The Processing of Small Hardware Fittings

This paper introduces the processing of small hardware fittings, which is a crucial step in the manufacturing industry. The processing of these fittings involves a series of operations, including cutting, shaping, polishing, and packaging. Each operation must be carried out with precision and care to ensure that the final product meets the required specifications. The use of modern machinery and technology has made the processing of small hardware fittings more efficient and accurate. However, it is still essential to have skilled workers who can monitor and adjust the machines to ensure that the processing is done correctly.

Small hardware fittings are essential components in various industries, including machinery, electronics, and automotive. These fittings are often made from metal materials and require precision processing to ensure their accuracy and reliability. In this article, we will explore the processing of small hardware fittings in detail.

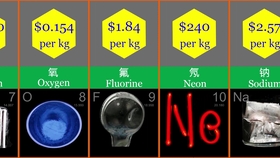

Small hardware fittings are typically made from copper, brass, steel, or aluminum. These materials are chosen for their mechanical properties, such as strength, hardness, and corrosion resistance. Additionally, these materials are easy to machine and provide good electrical conductivity.

Processing small hardware fittings involves several steps. First, the raw material is cut into the desired shape using a CNC machine or a manual cutting tool. Then, the cut pieces are cleaned and prepared for further processing. Next, the pieces are drilled or tapped to create the necessary holes or threads. Finally, the finished fittings are inspected for accuracy and quality before being packaged and shipped to the customer.

One of the key challenges in processing small hardware fittings is maintaining precision. These fittings are often very small in size, and any deviation from the desired dimensions can affect their performance in the final application. To ensure precision, manufacturers use high-quality CNC machines and measure the dimensions of each fitting using precision measuring instruments.

Another challenge is preventing contamination during processing. Small hardware fittings are often used in environments where cleanliness is crucial, such as in electronics or medical devices. Therefore, manufacturers take extra care to keep the workspace clean and use clean materials to ensure the contamination-free production of small hardware fittings.

In conclusion, processing small hardware fittings requires precision and care to ensure their accuracy and reliability. These fittings play a crucial role in various industries, and manufacturers continue to innovate and improve their processing techniques to meet the growing demand for these essential components. As the use of small hardware fittings increases in various applications, the need for efficient and cost-effective processing methods will also rise. Manufacturers will need to find ways to streamline their processes to meet these demands while maintaining or improving the quality of their products.

Articles related to the knowledge points of this article:

Title: The Jewelry Industry: A Glimpse into the Craftsmanship of Pearl Necklace Hardware Factories

Household Hardware Fittings: An Essential Guide

Tent Hardware Accessories: An Essential Guide

Used Hardware Accessories: A Buyer’s Guide

Title: 汕尾 - Your One-Stop Solution for Modern Hardware Parts Supply