Custom Hardware Manufacturing: A Look Inside the Factory

Custom hardware manufacturing is a process that requires precision and attention to detail. From the initial design phase to the final assembly process, each step must be carefully executed to ensure that the product meets the specifications and requirements of the customer. Inside the factory, you can find a range of machines and tools dedicated to cutting, shaping, and assembling the various components of the hardware. Workers must also adhere to strict safety regulations to ensure their own safety and the integrity of the product. In conclusion, custom hardware manufacturing is a complex process that demands precision and attention to detail to ensure that the final product is of high quality and meets the expectations of the customer.

The custom hardware manufacturing industry is a growing sector in the manufacturing industry. As businesses and individuals demand customized products to meet their specific needs, the role of the custom hardware manufacturer becomes increasingly important. This article provides a look inside a custom hardware factory to help readers understand the processes and procedures involved in creating these unique products.

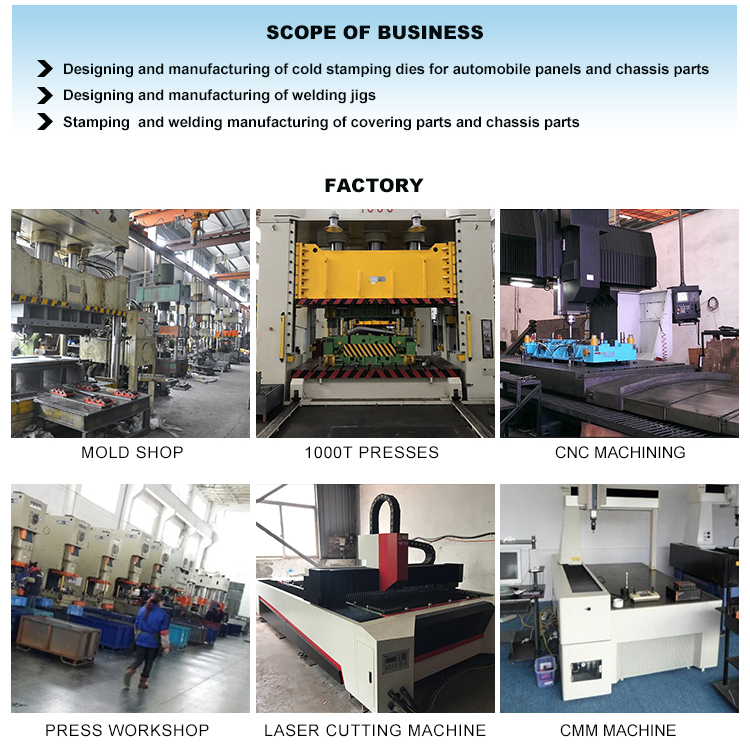

When you visit a custom hardware factory, you will notice that the environment is filled with machines, tools, and workers all focused on creating customized products. The factory is divided into different sections, each dedicated to a specific step in the manufacturing process. From raw material selection to cutting, bending, assembly, and packaging, each step is carefully controlled to ensure the highest quality product is produced.

One of the first steps in the manufacturing process is selecting the raw materials. Custom hardware manufacturers work with a variety of materials including steel, aluminum, brass, bronze, and stainless steel. Each material has its own unique properties and characteristics, which are considered when selecting it for a specific product. The manufacturer may also need to consider factors such as cost, availability, and recyclability.

Once the raw materials are selected, they are cut into the desired shapes using machines such as lasers, plasma cutters, or waterjets. The cutting process is precise and requires skilled operators to ensure accurate cuts are made. After cutting, the materials are often bent or formed into the desired shapes using presses or rollers. This process too requires precision and care to avoid any damage to the materials.

Once the raw materials have been cut and formed, they are ready for assembly. In this step, the various parts are brought together to create the finished product. This process can be manual or automated, depending on the complexity of the product being manufactured. For example, simple products may be assembled using manual labor, while more complex products may require robots or automated assembly lines.

Once the product is assembled, it is ready for testing and packaging. In this step, the manufacturer ensures that each product meets the required quality standards by conducting various tests such as strength tests, leak tests, and electrical tests. After testing, the products are packaged in appropriate packaging materials to protect them from damage during transportation and storage.

In conclusion, custom hardware manufacturing is a complex but rewarding process. By understanding the steps involved in creating customized products, you can appreciate the role of the custom hardware manufacturer in providing businesses and individuals with unique and functional products that meet their specific needs.

Articles related to the knowledge points of this article:

Title: Customization of Hardware Hanging Tags in Shaoxing: A Cultural and Industrial Exploration

Title: Elevating Home Decor with Customized Bronze Furniture Hardware

Title: Customizing Metalworking Equipment: A Comprehensive Guide

Title: Embracing Quality and Customer-centricity: An Insight into Bejings Customized Hardware Stores