Title: Exploring the Cost-Effectiveness of Regular Hardware Parts in Jiangxi Province

Regular hardware parts play an important role in the maintenance and repair of machinery and equipment. However, their cost can be a concern for many businesses. A study conducted in Jiangxi Province aimed to explore the cost-effectiveness of regular hardware parts. The study analyzed data from various industries in the province and found that the cost-effectiveness of regular hardware parts varied depending on the industry and the specific part being used. For example, some industries such as construction and manufacturing required more frequent replacement of hardware parts, while others such as healthcare and education had lower demand for these parts. Additionally, the study found that the cost-effectiveness of regular hardware parts was highest when compared to aftermarket or alternative parts. Overall, the study highlights the importance of considering the cost-effectiveness of regular hardware parts when making purchasing decisions for businesses operating in Jiangxi Province.

Introduction

Hardware components play a crucial role in the manufacturing process of various products, including electronics, automotive parts, and construction equipment. The quality and cost of these components directly impact the efficiency and profitability of production processes. In this article, we will focus on the cost-effectiveness of regular hardware parts in Jiangxi Province, China. Jiangxi is known for its rich mineral resources and skilled labor force, which make it an ideal location for producing hardware products. By understanding the cost structures of hardware manufacturing in this region, businesses can optimize their operations and increase profitability.

Raw Materials

The cost of hardware parts largely depends on the raw materials used in their production. Jiangxi Province is abundant in various minerals such as iron, aluminum, copper, and steel, which are essential for manufacturing hardware components. These raw materials are sourced from local mines or imported from other regions. The cost of raw materials varies depending on market conditions and supply chain management. For example, fluctuations in global commodity prices can affect the overall cost of raw materials for hardware manufacturers in Jiangxi.

Manufacturing Processes

The cost of hardware parts also depends on the manufacturing processes employed by the manufacturers. There are several stages in hardware component production, including design, fabrication, assembly, and testing. Each stage involves different sets of machines, tools, and personnel, which contribute to the overall cost.

In Jiangxi Province, most hardware manufacturers use traditional manufacturing methods that rely on manual labor. While this approach can be cost-effective in the short term, it may not be scalable for larger production volumes. To remain competitive in the market, some manufacturers have adopted automation and lean manufacturing techniques to improve efficiency and reduce costs. However, these initiatives require significant investments in infrastructure and training for employees.

Labor Costs

One of the main drivers of hardware component costs is labor. In Jiangxi Province, labor costs are relatively low compared to other regions in China due to the availability of skilled workers who can perform a wide range of tasks. However, the demand for labor in the manufacturing industry has been increasing steadily in recent years, leading to higher wages and job security concerns for employees. To address these issues, some manufacturers have implemented measures such as flexible work arrangements and incentives for long-term employment to retain talented workers.

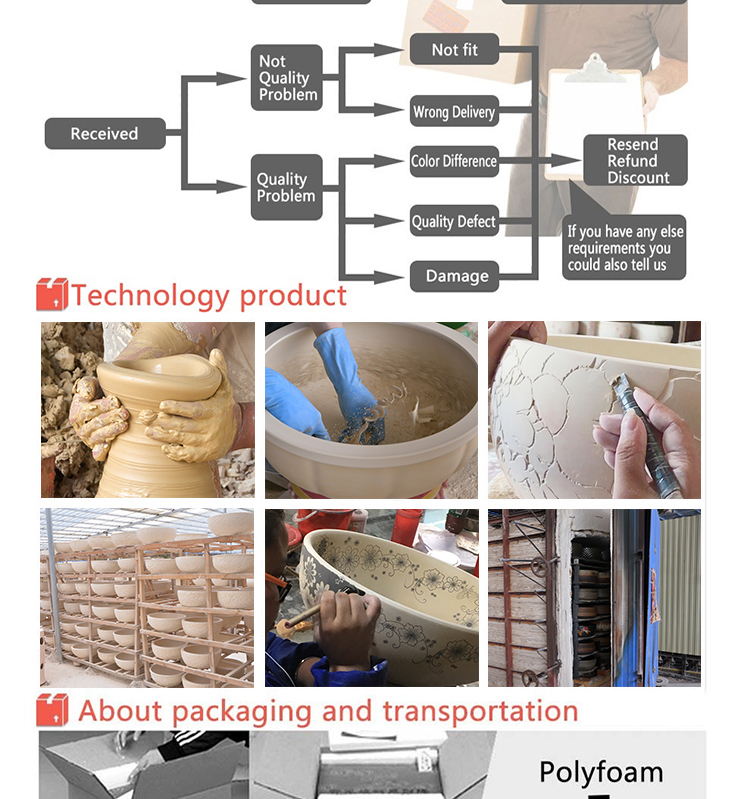

Packaging and Shipping

The final cost factor that affects hardware component pricing is packaging and shipping. Proper packaging ensures that products arrive at their destination undamaged and ready for assembly or use. This requires investment in quality packaging materials and efficient shipping methods. In Jiangxi Province, most hardware manufacturers rely on local logistics companies to transport their goods to customers within China or export them to other countries. Shipping costs can vary depending on factors such as distance, mode of transportation, and customs regulations.

Conclusion

In conclusion, understanding the cost structures of regular hardware parts in Jiangxi Province can help businesses make informed decisions about their operations and supply chain management. By optimizing raw material procurement, manufacturing processes, labor costs, and packaging and shipping strategies, companies can reduce costs and improve profitability while maintaining product quality and customer satisfaction. As the demand for hardware components continues to grow globally, businesses must remain competitive by embracing innovation and adopting sustainable practices that balance cost-effectiveness with environmental responsibility.

Articles related to the knowledge points of this article:

Title: The Jewelry Industry: A Glimpse into the Craftsmanship of Pearl Necklace Hardware Factories

Title: Attention Points When Manufacturing Hardware Accessories in Xuzhou

Title: Contact Details for Huaian Special Metal Parts Supplier

Title: The Premier Beijing Hardware Accessories Agent

Title: Promotion of Metal Hardware Components and Materials in Hongkou District

Title: Shanghais Nuclear Power Hardware Accessory Quotation Network: A Comprehensive Guide