Exploring the Cost Structure of Non-Standard Customized Metal Hardware in Shenzhen

As a fast-growing industry in Shenzhen, non-standard customized metal hardware has attracted the attention of many manufacturers and consumers alike. However, the cost structure of this industry remains a mystery to many. To better understand the cost structure of non-standard customized metal hardware in Shenzhen, a thorough analysis is needed. This study aims to explore the various factors that contribute to the overall cost of manufacturing and distributing non-standard customized metal hardware products in this region. The analysis will focus on the production process, raw materials, labor costs, transportation expenses, and other related costs. By examining these factors in detail, we hope to provide valuable insights into how non-standard customized metal hardware businesses can improve their operations and increase profitability. Ultimately, our research will help companies in this field make better decisions and compete more effectively in the global market.

In the bustling metropolis of Shenzhen, China, a city renowned for its innovative spirit and technological prowess, a niche industry thrives: the customization of metal hardware. This industry involves the production of bespoke metal components for various applications, ranging from consumer goods to commercial equipment. While the demand for these customized products is substantial, the process of creating them can be complex and requires specialized knowledge and skills. One key factor that determines the cost of non-standard customized metal hardware in Shenzhen is the complexity of the design and the materials used. In this article, we will explore the various factors that contribute to the cost structure of non-standard customized metal hardware in Shenzhen, highlighting the role played by each element and how they impact the final price.

The first factor that affects the cost of non-standard customized metal hardware in Shenzhen is the design complexity of the product. A simple design with standard dimensions and shapes can be produced more efficiently and at a lower cost. However, products with intricate designs or unique shapes require more time and resources to produce, which increases the overall cost. The design phase is critical as it sets the foundation for the entire production process. Without a well-designed product, the manufacturing process may become unnecessarily complicated, leading to additional costs. Therefore, it is essential to invest in thorough design research and development to ensure that the final product meets both functional and aesthetic requirements while keeping production costs low.

Another critical factor that contributes to the cost of non-standard customized metal hardware in Shenzhen is the materials used. Different metals have different properties, such as strength, flexibility, and corrosion resistance, which impact their suitability for specific applications. For example, aluminum is a lightweight and versatile metal that is commonly used in consumer products, such as bicycles and airplane parts. However, it can be prone to scratches and dents, which may affect its appearance and durability. On the other hand, stainless steel is resistant to corrosion and can withstand harsh environmental conditions, making it ideal for outdoor equipment and appliances. However, it is heavier than aluminum and may require additional fabrication steps to achieve a desirable finish. Therefore, choosing the right material based on the specific application requirements is crucial to minimize costs without compromising performance.

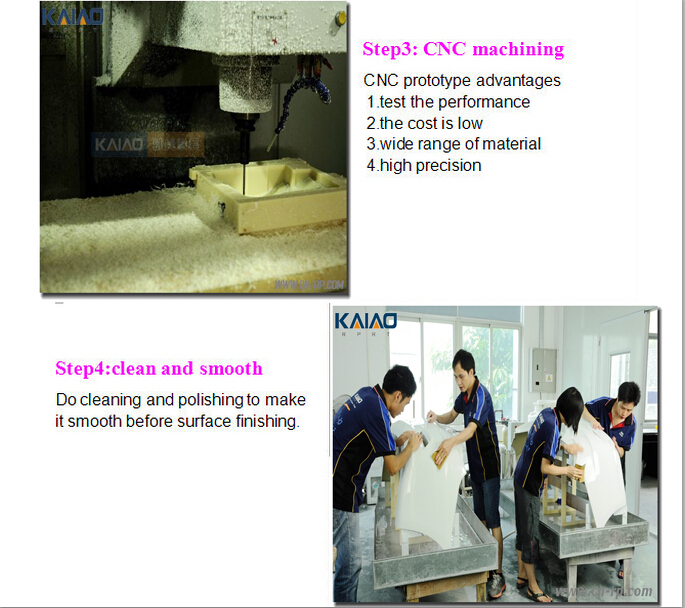

During the manufacturing process, several stages contribute to the overall cost of non-standard customized metal hardware in Shenzhen. These stages include prototyping, engineering, cutting, bending, drilling, and assembly. Each stage involves a set of operations that require specialized tools and equipment. For example, prototyping may involve creating small-scale models to test design concepts, while engineering may involve calculating material usage and structural analysis. Cutting, bending, drilling, and assembly are all critical processes that require skilled workers who can operate specialized machinery effectively. The complexity of these stages varies depending on the product design and material choice. In general, products with more complex geometries or multiple components require more extensive manufacturing processes, which increase production costs. As a result, manufacturers must balance cost-effectiveness with quality to remain competitive in the market.

Finally, the location of the manufacturer also plays a role in determining the cost of non-standard customized metal hardware in Shenzhen. Shenzhen is home to several large-scale industrial districts that specialize in manufacturing various types of metal products. These districts offer access to advanced manufacturing technology and skilled labor, which helps reduce costs compared to operating in remote locations. Additionally, many international companies have established factories in Shenzhen to take advantage of its proximity to major shipping ports and customer bases in Asia. However, these benefits come at a premium cost due to higher overhead expenses such as rent and utilities. Therefore, manufacturers must carefully consider their supply chain strategies when deciding where to operate their business in Shenzhen.

In conclusion, understanding the cost structure of non-standard customized metal hardware in Shenzhen involves analyzing several key factors that influence production costs. These factors include design complexity, materials selection, manufacturing processes, and geographical location. By considering each element carefully and balancing cost-effectiveness with quality, manufacturers can develop innovative products at competitive prices while maintaining high standards of craftsmanship. As Shenzhen continues to evolve as a hub for advanced manufacturing technologies and industries, it will be crucial for manufacturers to stay ahead of trends and adapt accordingly to maintain a competitive edge in the global marketplace.

Articles related to the knowledge points of this article:

Iron Hardware Fittings: The Backbone of Construction

A Journey of Naming: Creating a Unique Name for a Hardware Accessory