Title: Customization of Automobile Hardware Processing in Dongguan: An Overview of the Industry and Its Challenges

Customization of automobile hardware processing in Dongguan is a rapidly growing industry. It involves the manufacturing and assembly of various automotive parts that are customized according to customer requirements. This industry has experienced significant growth in recent years, with many local companies expanding their operations in this area.However, there are several challenges faced by the industry. One of the biggest challenges is the high level of competition in the market. Many small and medium-sized enterprises (SMEs) are involved in this industry, which makes it difficult for larger players to gain a foothold. Another challenge is the limited technological capabilities of SMEs, which can lead to delays in product development and delivery.Despite these challenges, the industry is expected to continue its growth trajectory in the coming years. This is due to the increasing demand for customized automotive parts, as well as the government's support for the development of the industry. To overcome the challenges faced by the industry, it is important for SMEs to focus on improving their technological capabilities and investing in research and development. This will enable them to stay competitive and meet the needs of customers in the ever-changing automotive industry.

Introduction

Dongguan, a city located in the eastern part of China, has become a hub for automobile manufacturing and hardware processing. In recent years, there has been a surge in demand for customized automotive hardware products due to the growing popularity of car modification and personalization. This has led to the development of a vibrant industry that offers a wide range of services, including design, prototyping, machining, and assembly. However, despite its success, the industry faces several challenges that need to be addressed to ensure its continued growth and sustainability.

The Automotive Hardware Processing Industry in Dongguan

The automotive hardware processing industry in Dongguan can be broadly categorized into three main segments: design and prototyping, machining, and assembly. Each segment plays a crucial role in the production process and requires specialized skills and equipment.

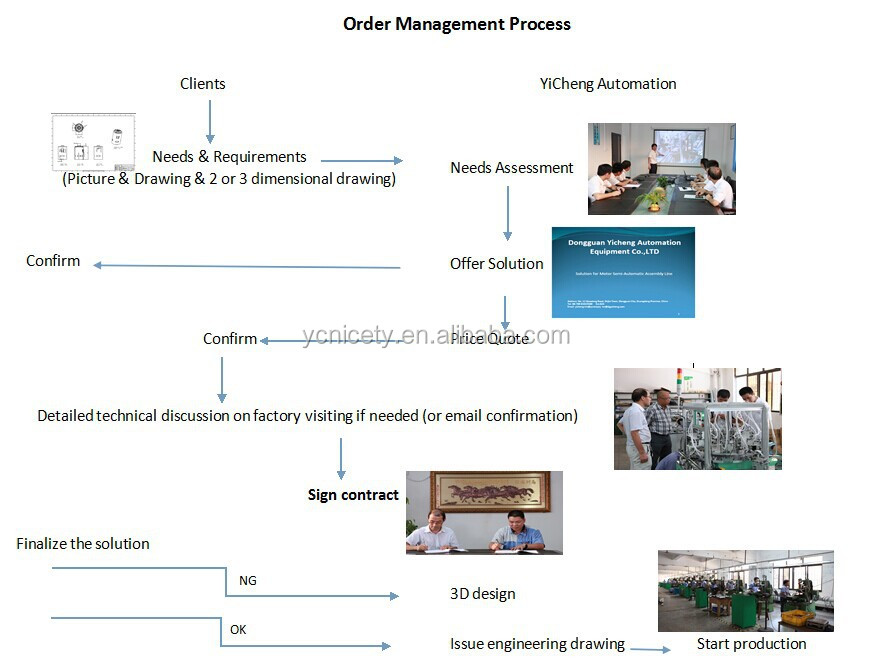

Design and prototyping: The design and prototyping stage involves creating detailed drawings and models of the hardware components that will be manufactured. This is followed by the use of computer-aided design (CAD) software to create 3D models of the parts. The designs are then verified for accuracy and feasibility before moving onto the next stage.

Machining: In this stage, the raw metal materials are transformed into finished parts using various cutting tools such as lathes, mills, and drills. The quality of the final product depends on the skill and experience of the machine operators, as well as the precision of the machines themselves.

Assembly: Once the components have been machined to perfection, they are assembled into complete units or systems. This may involve additional processes such as painting, coating, and polishing to enhance the appearance and functionality of the finished product.

Challenges Facing the Automotive Hardware Processing Industry in Dongguan

Despite its rapid growth, the automotive hardware processing industry in Dongguan faces several challenges that need to be addressed to ensure its continued success. These include:

1、Skill shortages: There is a shortage of skilled workers with expertise in advanced manufacturing technologies such as CAD/CAM, CNC, and other digital tools. This makes it difficult for companies to keep up with the pace of innovation and meet customer demands for high-quality products. To overcome this challenge, there is a need for greater investment in education and training programs that can equip the workforce with the necessary skills.

2、Quality control: Ensuring the quality of automotive hardware products is critical to maintaining customer trust and satisfaction. However, achieving consistent quality standards can be challenging, especially when working with large volumes of parts or when dealing with complex geometries. To address this challenge, companies must implement rigorous quality control measures throughout their production processes, including regular inspections, audits, and testing.

3、Supply chain management: The automotive hardware processing industry relies heavily on raw materials and components from various suppliers around the world. Managing these supply chains effectively can be a complex task that requires close coordination between manufacturers, logistics providers, and regulatory agencies. To improve supply chain efficiency and reduce costs, companies should adopt lean manufacturing principles and explore new sourcing strategies such as local sourcing or collaborative partnerships.

4、Environmental regulations: The automotive hardware processing industry is subject to strict environmental regulations designed to minimize waste, reduce pollution, and conserve natural resources. Companies must comply with these regulations to avoid costly penalties and maintain public trust. To achieve this goal, they should invest in sustainable technologies such as energy-efficient machines and recycling facilities, as well as develop eco-friendly business practices that promote waste reduction and resource conservation.

5、Innovation: The automotive hardware processing industry is constantly evolving, with new technologies and trends emerging every year. Companies that fail to innovate risk falling behind their competitors and losing market share. To stay ahead of the curve, they should foster a culture of innovation that encourages creativity, experimentation, and continuous learning

Articles related to the knowledge points of this article:

Customizing Window Hardware in Ningbo: A Detailed Guide

CUSTOM METAL FABRICATION IN SHANTOU: A PRECISE CRAFTSMANSHIP

Title: Crafting Custom Metal Toys: A Unique and Personalized Experience