The art of polishing in hardware accessories industry

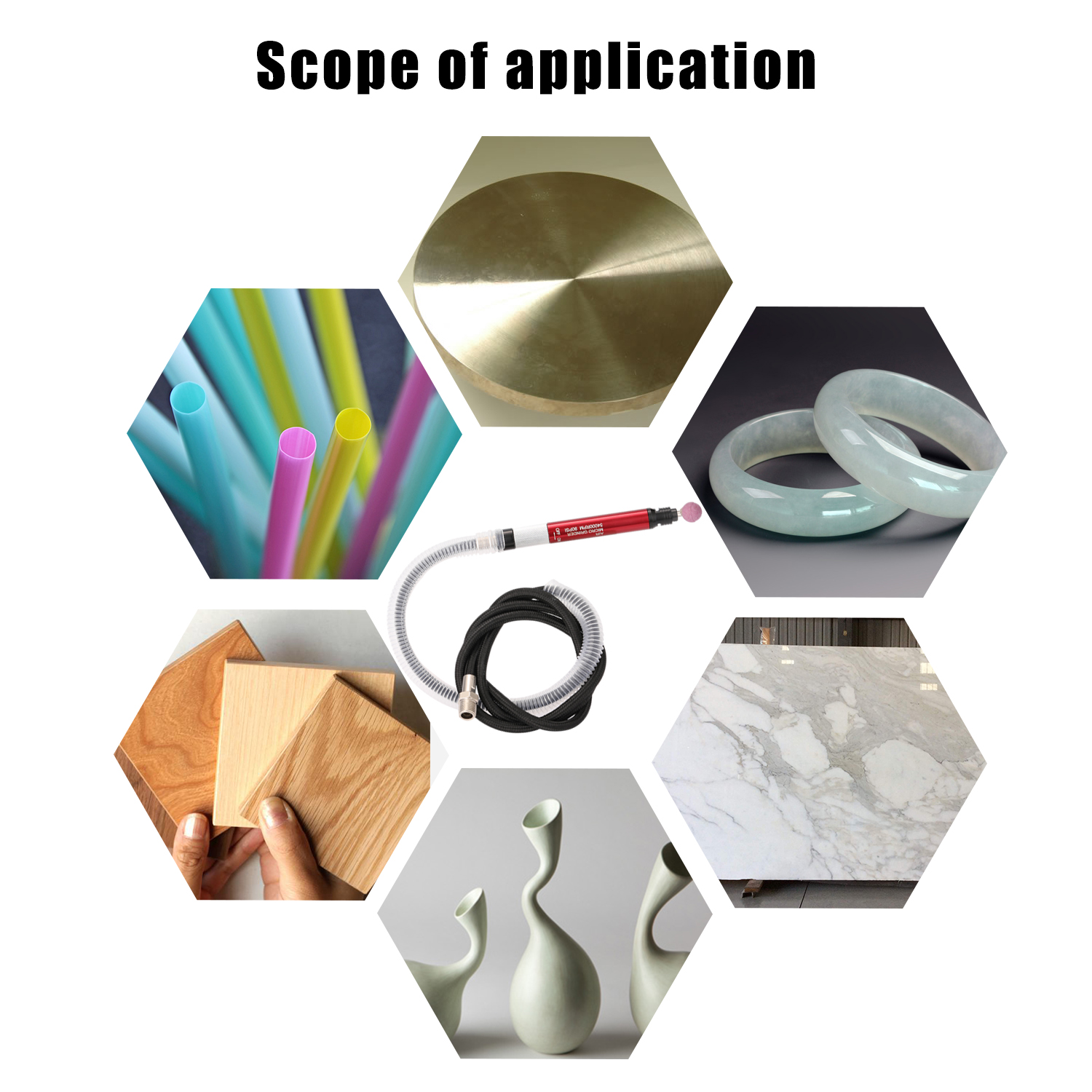

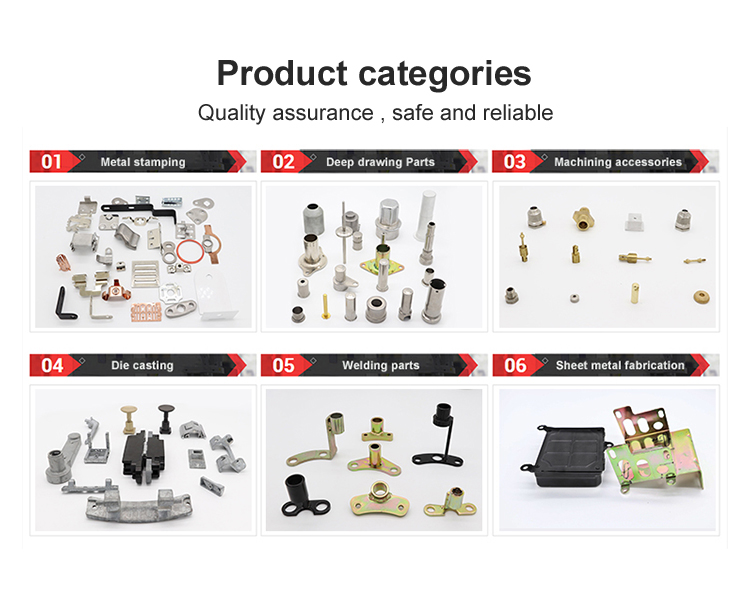

In the hardware accessories industry, polishing is an essential process that involves removing imperfections and smoothing out surfaces to achieve a high level of precision and quality. This art form requires a combination of skill and patience, as each piece must be meticulously worked upon to ensure its smooth and seamless finish. Polishers use a variety of tools and techniques to achieve the desired results, from using sandpaper to buffing compounds. By removing scratches, marks, and unevenness from the surface, polishing ensures that the hardware accessory is ready for its intended use. This process is particularly important in industries where precision and appearance are critical, such as automotive, aerospace, and jewelry manufacturing.

In the hardware accessories industry, polishing is a crucial process that ensures the quality and longevity of the products. The skilled craftsmanship behind this process has been passed down through generations, and it continues to evolve with the advancement of technology and new materials. This article delves into the history, techniques, and importance of polishing in hardware accessories.

History of polishing in hardware accessories

The history of polishing in hardware accessories can be traced back to ancient times. Metals were often polished to enhance their appearance and protect them from rusting. In the Middle Ages, polishing techniques were further developed, with the use of abrasive compounds to smoothen and brighten the surfaces of metals. By the 19th century, polishing had become an integral part of hardware accessories manufacturing, with the development of new polishing machines and techniques.

Techniques of polishing in hardware accessories

There are several techniques used in polishing hardware accessories. One common technique is mechanical polishing, which involves using abrasive compounds or pastes to remove imperfections from the surface of the metal. Chemical polishing, on the other hand, involves using acids or other chemicals to etch or dissolve away surface impurities. Another technique is electro-chemical polishing, which combines elements of both mechanical and chemical polishing to create a smooth, highly reflective surface.

Importance of polishing in hardware accessories

Polishing hardware accessories is essential for several reasons. Firstly, it enhances the appearance of the product by removing scratches, blemishes, and other imperfections from the surface. This gives the accessory a more aesthetically pleasing appearance that can enhance its value and appeal to customers. Secondly, polishing also protects the metal from rusting or corroding, which can occur when the metal is exposed to moisture or oxygen. By removing these elements, polishing creates a smoother, more durable surface that can withstand the elements better. Finally, polishing improves the functionality of the accessory by removing any rough or uneven surfaces that could interfere with its performance or lifespan. A smoothly polished surface will be easier to use and will last longer before showing signs of wear and tear.

In conclusion, polishing in hardware accessories is not just a cosmetic process but one that adds value and durability to the product. It is essential for preserving the appearance and functionality of hardware accessories for years to come. With the right techniques and equipment, polishing can transform ordinary hardware into something that is both beautiful and functional.

Articles related to the knowledge points of this article:

Title: Selecting Hardware Accessories for Xinchang: A Comprehensive Guide to Getting the Best Deals

The Hardware Fitting Hinge: A Pivotal Component in Construction and Renovation

Shoe Buckle Hardware Accessories: Key Components for Shoe Production

Title: Billiards Hardware Accessories: An Introduction to their Importance and Application