Title: The Art of Precision Metalworking: An Exploration of Copper Component Manufacturing

In the world of industrial manufacturing, precision metalworking is a discipline that requires skill, expertise, and a deep understanding of the properties of various metals. One such field that stands out for its complexity and attention to detail is copper component manufacturing. As a leading manufacturer of precision copper parts for a diverse range of industries, our company has honed our craft over many years, striving to provide clients with products that meet the highest standards of quality and performance. In this article, we will take a closer look at the process of crafting precision copper components and the role that technology plays in ensuring accuracy and efficiency.

The Process of Crafting Copper Components

The production process for copper components begins with the selection of raw materials. Our suppliers source high-quality copper alloys that are ideal for the specific application in question. Once the materials have been procured, they are carefully inspected to ensure their purity and consistency. Next, the raw copper bars are cut to size and prepared for further processing. This may involve cleaning, deburring, and polishing the material to remove any surface contaminants and enhance its mechanical properties.

The next step in the production process is the creation of custom-designed shapes and forms from the copper bars. This is done using specialized tools and equipment such as lathes, milling machines, and CNC routers, which allow us to produce complex geometries with exceptional precision. During this stage, engineers work closely with technicians to ensure that the final product meets the required specifications and tolerances.

Once the shape and form have been created, the copper components are subjected to a series of tests to assess their strength, durability, and other relevant properties. This may include tension testing, load testing, or other types of destructive testing that simulate real-world operating conditions. If necessary, the components are modified or reworked until they meet the desired criteria.

Finally, the finished copper components are cleaned and ready for assembly into finished products. This may involve adding hardware such as screws, nuts, and bolts, or attaching other components such as sensors or actuators. In some cases, additional surface treatments such as painting or plating may be applied to enhance the aesthetic appeal of the final product and protect it from corrosion.

The Role of Technology in Precision Copper Component Manufacturing

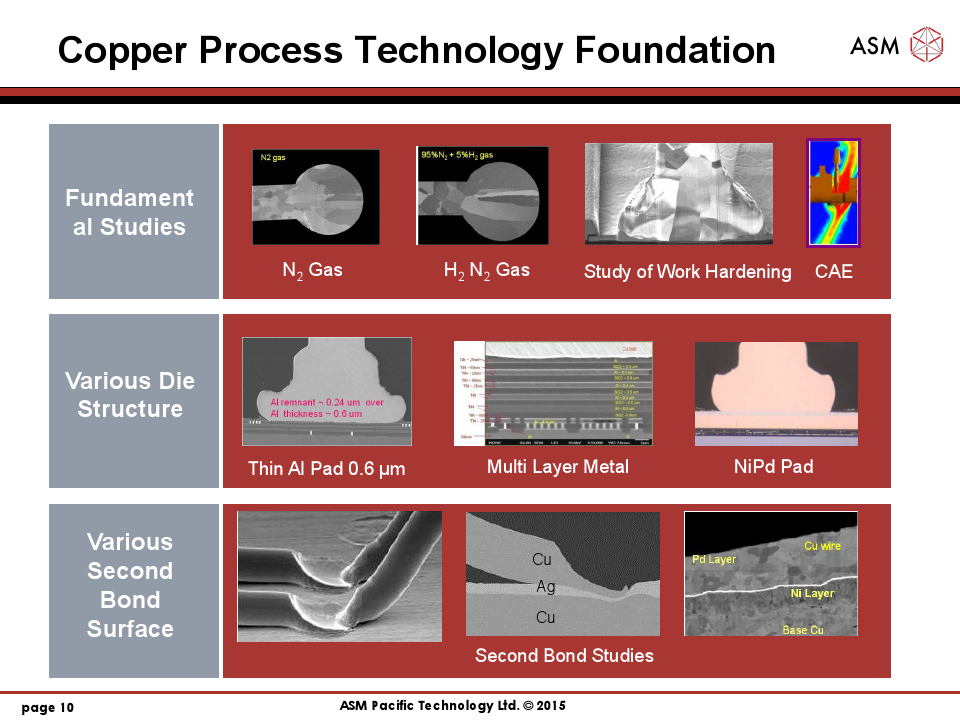

Technology plays a crucial role in ensuring the accuracy and efficiency of copper component manufacturing. One area where technology has had a significant impact is in the development of computer-aided design (CAD) software that allows engineers to create detailed models and simulations of their designs before they are translated into physical components. This not only reduces the time and effort required to develop new products but also improves the accuracy of the designs by catching potential errors early in the process.

Another area where technology has been instrumental is in the development of advanced manufacturing techniques such as additive manufacturing (AM), which allows for the creation of complex geometries with minimal waste and cost. By using specialized 3D printers or other AM equipment, we can produce customized copper components on demand without having to invest in costly tooling or machinery. This not only reduces our costs but also enables us to quickly respond to changing market demands and customer preferences.

Other technologies that are used in precision copper component manufacturing include robotic welding systems, laser cutting machines, and CNC machining centers. These tools allow us to achieve high levels of precision and consistency throughout the production process, minimizing the risk of defects or inconsistencies that could negatively impact the performance of the final product.

Conclusion

In conclusion, precision copper component manufacturing is a demanding and complex discipline that requires a deep understanding of metallurgy, engineering principles, and advanced technologies. As a leading provider of precision copper components for a wide range of industries, we pride ourselves on our commitment to excellence and our ability to deliver products that meet the highest standards of quality and performance. Whether you are looking for custom-designed components or standard off-the-shelf items, we have the expertise and resources to help you achieve your goals and succeed in today's competitive marketplace.

Articles related to the knowledge points of this article:

Tianjin Hardware Manufacturers: A Stronghold of Quality and Innovation

Hebei Advanced Hardware Manufacturers