Title: Customizing Metallic Inks Production: A Comprehensive Guide for Hardware and Electronics Industries

Customizing metallic inks production is a crucial step for the hardware and electronics industries. These inks are used in various applications such as printing, labeling, and coating. To ensure quality control and customer satisfaction, customization can be done to suit specific requirements. This article provides a comprehensive guide on how to customize metallic inks production. It includes understanding the properties of metallic inks, selecting the appropriate equipment, determining the formulation for custom inks, and implementing quality control measures. The article also discusses the benefits of customization, such as increased productivity, reduced waste, and improved product differentiation. By following these guidelines, businesses can produce high-quality metallic inks that meet their unique needs and stand out in the competitive market.

Introduction:

Metallic inks are widely used in various industries, including the hardware and electronics sectors. These inks offer unique properties such as durability, resistance to wear and tear, and excellent printing accuracy. However, finding a reliable manufacturer that can produce high-quality metallic inks tailored to specific needs can be challenging. This article aims to provide an overview of how to select the right supplier for custom metallic ink production, highlighting the key factors to consider when working with a hardware or electronics company.

1. Understanding Your Requirements: Before you start searching for a metallic ink manufacturer, it's crucial to understand what specific attributes you require from your inks. This includes factors such as color consistency, gloss level, printability, and application methods (e.g., screen printing, offset printing). Having a clear idea of your requirements will help you narrow down your search and identify potential suppliers who can meet your specific needs.

2. Researching Potential Manufacturers: Once you have a list of requirements, it's time to start researching potential manufacturers. Look for companies that have experience producing metallic inks and have a reputation for delivering high-quality products. Check online reviews, industry publications, and trade associations to learn more about their capabilities and customer satisfaction levels. It's also a good idea to request samples of their metallic inks to evaluate their quality firsthand.

3. Assessing Technical Expertise: When evaluating potential manufacturers, it's important to assess their technical expertise. Ask questions about their processes for formulating and manufacturing metallic inks, as well as any specialized equipment or technologies they use. A manufacturer with a deep understanding of the technical aspects of metallic ink production is likely to be more capable of tailoring their products to meet your specific needs.

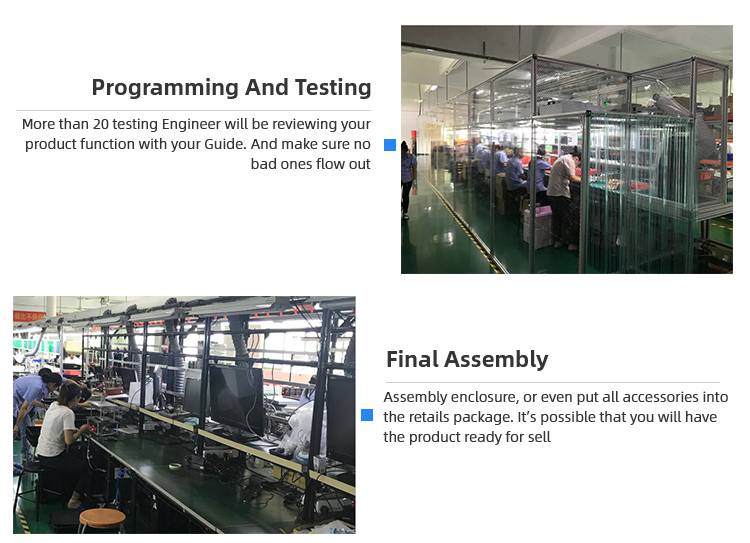

4. Quality Control Measures: Look for a manufacturer that has robust quality control measures in place to ensure consistent product quality. Ask about their testing protocols and inspection procedures, as well as any certifications or standards they adhere to (e.g., ISO, SGS). A manufacturer with strong quality control measures is less likely to produce inconsistent or low-quality products.

5. Cost Considerations: While cost is not the only factor to consider when selecting a manufacturer, it's still worth comparing pricing and negotiating terms with multiple suppliers. Be aware that lower prices may not always translate to better quality, so it's important to balance cost with other factors like technical expertise, delivery times, and customer support.

6. Customer Support: Finally, consider the level of customer support offered by potential suppliers. Ask about their response times, communication channels (e.g., email, phone), and availability for consultations or technical assistance. A manufacturer with excellent customer support is more likely to be responsive and helpful if you encounter any issues or need guidance during the customization process.

Conclusion:

Customizing metallic ink production requires careful consideration of various factors, including your specific requirements, potential manufacturers' technical expertise, quality control measures, cost considerations, and customer support. By taking the time to research and evaluate potential suppliers thoroughly, you can find a provider who can deliver high-quality metallic inks tailored to your needs. Remember that investing in quality metallic inks can pay off in the long run by ensuring better print accuracy, increased durability, and improved product performance.

Articles related to the knowledge points of this article:

Title: Exploring the World of Customized五金锁具 Manufacturer in Jinjiang, China

Customizing Baggage Hardware Components: A Detailed Guide

Title: Customization of Metal Hardware: A Comprehensive Guide

Custom Injection Molding in Hubei, China: A Comprehensive Guide

Title: Chongqing Hardware Customization Manufacturers

Customized Hardware Import for Quality Assurance in Manufacturing Processes