Title: Exploring the World of Hardware Pagination: A Comprehensive Guide to Wholesale Hardware Pagination

Wholesale hardware pagination is a crucial aspect of the industry that requires meticulous attention to detail. This comprehensive guide aims to explore the world of hardware pagination, providing readers with an in-depth understanding of the process and its importance in ensuring efficient distribution of hardware products. From the basics of pagination to advanced techniques, this guide covers it all. It highlights the various factors that contribute to successful hardware pagination, such as product selection, pricing, and marketing strategies. The guide also delves into the role of technology in hardware pagination, discussing the use of software and digital tools to streamline the process. Additionally, it explores the challenges faced by hardware pagination professionals and provides practical tips for overcoming them. Overall, this guide serves as a valuable resource for anyone looking to enhance their knowledge and skills in wholesale hardware pagination, ensuring they can navigate the complex world of hardware distribution with ease.

In the world of manufacturing and construction, few things are as fundamental as hardware pagination. These small but mighty metal components play a crucial role in the assembly and closure of a vast array of products, from furniture to machinery, and they are an essential component of any industrial or commercial supply chain.

At their core, hardware pagination involves the cutting, bending, and shaping of metal sheets into various shapes and sizes that can be used to connect two or more pieces of material together. This process requires precision, accuracy, and expertise, and it is one that is carried out by thousands of manufacturers and suppliers around the globe.

Among these manufacturers and suppliers, a select group stands out for their exceptional quality, reliability, and innovation - they are the wholesale hardware pagination suppliers. These companies work closely with factories across the world to source high-quality materials and advanced equipment to produce hardware pagination components that meet the demanding needs of their customers.

This article aims to explore the world of hardware pagination wholesale, providing readers with a comprehensive guide to understanding this complex and vital industry. We will examine the different types of hardware pagination, the materials used, the manufacturing process, and the importance of quality control in this critical stage of production.

Part One: Understanding Hardware Pagination

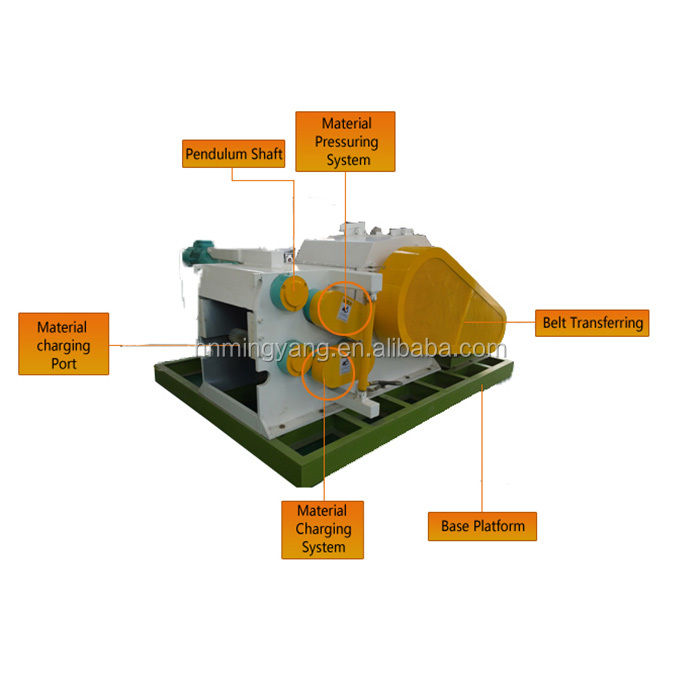

At its most basic level, hardware pagination is the process of joining two or more pieces of material together using metal components such as hinges, brackets, and connectors. The specific type of hardware pagination used will depend on the application and the materials involved. For example, door hinges use a combination of metal components to provide stability and strength, while drawer glides require precise alignment to ensure smooth operation.

Hardware pagination is typically carried out in a factory environment using specialized equipment such as press brakes, lathes, and welding machines. These machines allow manufacturers to create complex shapes and designs that would be difficult or impossible to achieve by hand. The quality of the hardware paginating components produced will depend on several factors including the materials used, the precision of the equipment, and the expertise of the workers operating it.

Part Two: Materials for Hardware Pagination

The choice of materials used in hardware pagination can have a significant impact on the performance and durability of the final product. Commonly used metals for hardware pagination include stainless steel, aluminum, and brass. Each has its own unique properties that make it suitable for different applications.

Stainless steel is a popular choice due to its resistance to corrosion and high strength-to-weight ratio. It is often used in applications where exposure to water or other chemicals is possible. Aluminum is lightweight and durable, making it suitable for applications where weight savings are important. It is also resistant to corrosion, although it is more susceptible to scratches than stainless steel. Brass is a warm-colored metal that is resistant to tarnish and rust. It is commonly used in decorative applications.

Part Three: Manufacturing Process for Hardware Pagination

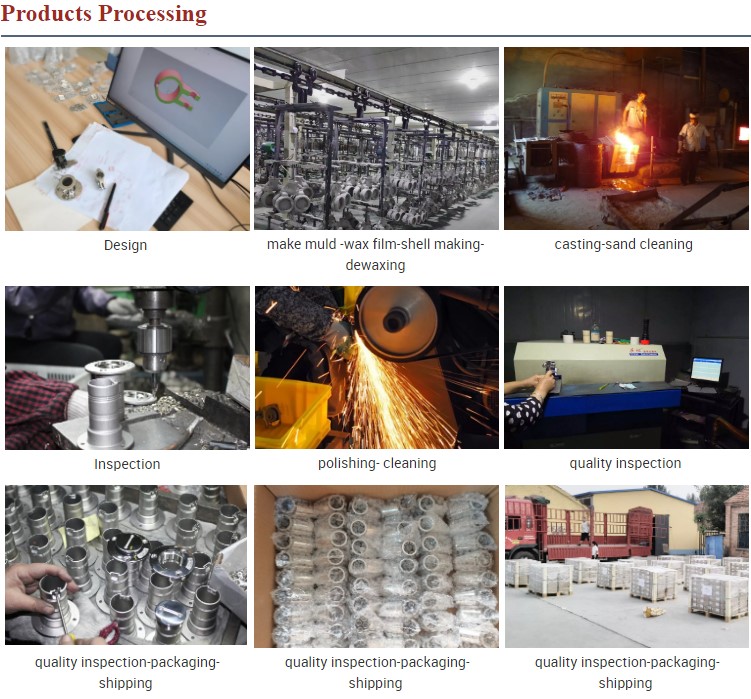

The manufacturing process for hardware paginating components begins with the selection of raw materials and the cutting of them into shape using specialized machinery such as presses, lasers, or CNC routers. Next, the components are shaped using further machinery such as bending machines or lathes. Finally, the components are finished by welding, drilling, or painting as necessary.

Quality control is a critical stage in the hardware paginating process. Manufacturers must ensure that each component meets strict specifications for strength, durability, and precision. This often involves subjecting components to rigorous testing using methods such as X-ray scanning or stress analysis. Any defects or issues with a component must be corrected before it can be sold or installed in a final product.

Part Four: The Importance of Quality Control in Hardware Pagination

Quality control is essential in all stages of production, but it is particularly critical in hardware paginating components due to the complexity of the manufacturing process. Any defects or issues with a component can have far-reaching consequences

Articles related to the knowledge points of this article:

Title: Finding the Best Hardware Wholesale Market in Fuzhou

Silver Chi Hardware Wholesale: The Comprehensive Guide