Title: The Art of Manufacturing Sanitary Ware Hardware: A Masterclass from a Professional Sanitary Ware Hardware Manufacturer

The art of manufacturing sanitary ware hardware requires a high level of precision and expertise. As a professional sanitary ware hardware manufacturer, we understand the importance of delivering products that not only meet but exceed customer expectations. Our masterclass covers the key aspects of this process, from selecting the right materials to ensuring consistent quality control throughout the production cycle. We delve into the intricacies of design, incorporating innovative features that enhance functionality and durability. Our state-of-the-art manufacturing facilities enable us to produce products that are both aesthetically pleasing and highly functional. We also emphasize the importance of maintaining strict hygiene standards during production, minimizing the risk of contamination. By following our comprehensive guidelines, manufacturers can create sanitary ware hardware that is not only reliable but also highly desirable in today's market. Whether you are a seasoned industry professional or just starting out, our masterclass offers valuable insights that will help you take your manufacturing processes to the next level.

In the world of sanitaryware hardware, few things are as critical to the success of a product as the quality of its manufacturing process. At [Sanitary Ware Hardware Manufacturer's Name], we have dedicated ourselves to perfecting this process, creating hardware that is not just functional and durable but also aesthetically pleasing. In this article, we will take you through our manufacturing journey, highlighting the key steps we follow to ensure that every piece of hardware we produce meets the highest standards of quality.

Starting from Raw Materials

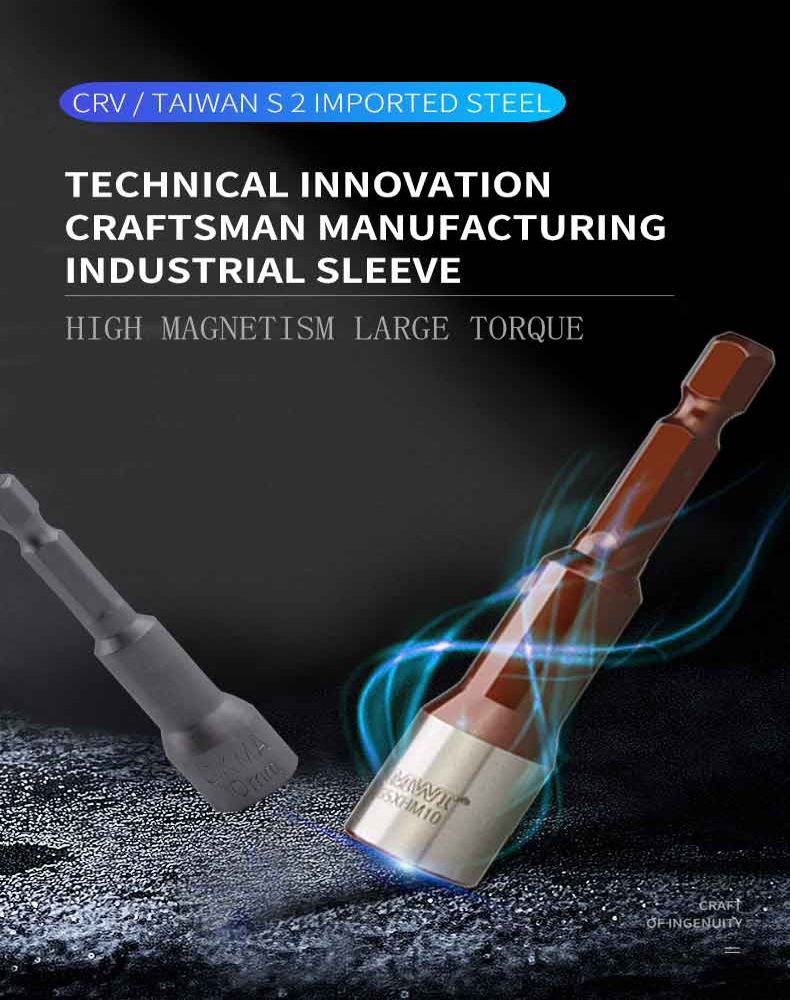

The first step in our process is selecting raw materials. We only work with suppliers who provide us with high-quality stainless steel, brass, and other metal components that can withstand the rigors of use in a sanitary environment. Our team of experts carefully scrutinizes each supplier to ensure they meet our rigorous quality requirements. Once we have selected our raw materials, we move onto the next step.

Design and Engineering

Our team of experienced engineers plays a crucial role in ensuring that every piece of hardware we produce is functional, efficient, and easy to install. They use state-of-the-art software to design our products, taking into account factors such as material strength, durability, and aesthetic appeal. Our engineers are passionate about their work and are constantly striving to improve our designs, seeking out new techniques and innovations to enhance our hardware's performance. They also collaborate closely with our sales and marketing teams to understand customer needs and preferences and incorporate these into our designs.

Manufacturing Process

The manufacturing process starts with cutting the raw materials into precise shapes and sizes using specialized machines. Our factory has invested heavily in modern machinery that allows us to produce high volumes of hardware efficiently and accurately. We follow strict quality control measures at every stage of the manufacturing process to ensure that our hardware meets our exacting standards. Our team of skilled technicians checks each piece of hardware for accuracy, ensuring that it meets the specifications outlined in our designs.

Surface Treatment

Once we have produced our hardware, we apply various surface treatments to enhance its durability, corrosion resistance, and aesthetic appeal. We use advanced technologies such as electroplating, polishing, and sandblasting to achieve these goals. These treatments not only add a layer of protection to our hardware but also give it a sleek, polished finish that looks great in any sanitary setting.

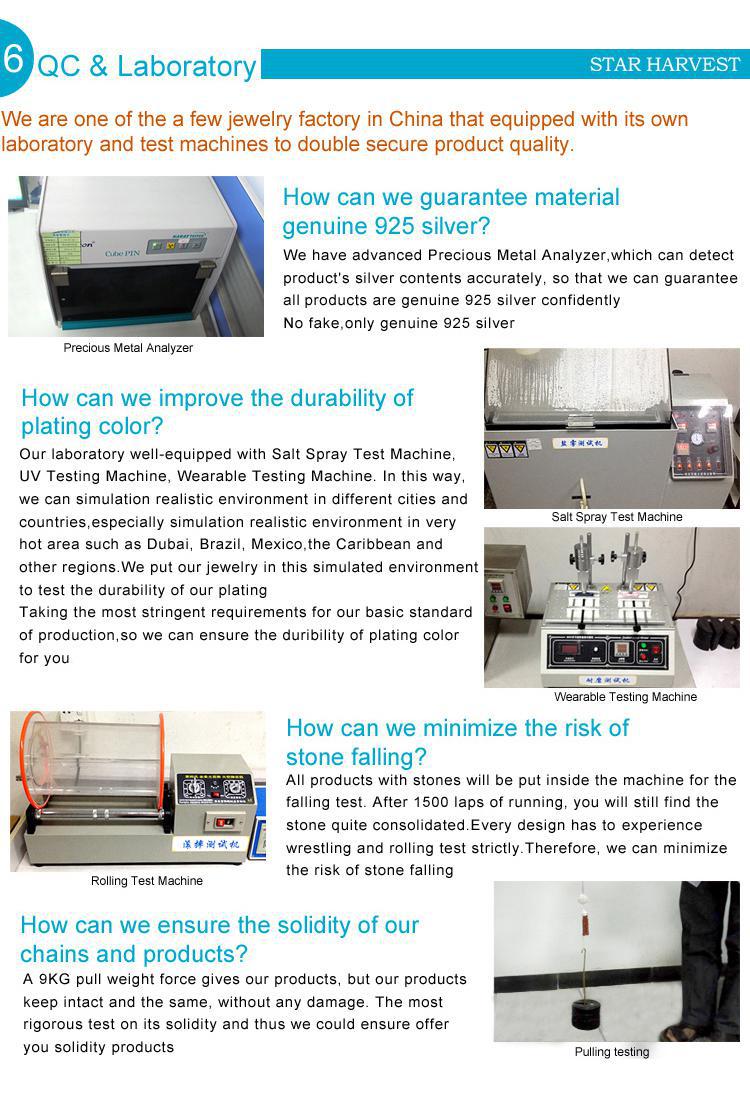

Quality Control

Before we ship our hardware to customers, we conduct extensive quality control checks to ensure that it meets our high standards. Our team of quality control experts inspects every piece of hardware, checking for defects such as cracks, scratches, or discoloration. They also test the functionality of each piece to ensure that it works correctly in different settings. If any hardware fails our inspection, we rework it or replace it if necessary. This ensures that every piece of hardware we ship to customers is top-quality and ready to meet their needs.

Conclusion

At [Sanitary Ware Hardware Manufacturer's Name], we believe that quality is not an option but a fundamental requirement for success in the sanitaryware hardware industry. From our dedication to selecting only the highest-quality raw materials to our meticulous attention to detail throughout the manufacturing process, we strive to deliver exceptional products that exceed our customers' expectations. We are proud of what we do and are committed to continuing to innovate and improve as we work towards building a better future with every piece of hardware we produce.

Articles related to the knowledge points of this article:

Dongguan Spring Hardware Manufacturers

Title: Exploring the World of Copper and Hardware Manufacturing in Taizhous Proximity

Title: A Comprehensive Guide to the Top Hardware Manufacturers in Guannan District