Title: The Evolution of Lighting Industry: From Traditional Methods to Advanced Laser Cutting Technology in Hardware Manufacturers

Title: The Evolution of Lighting Industry: From Traditional Methods to Advanced Laser Cutting Technology in Hardware ManufacturersThe lighting industry has undergone significant transformation over the years, from traditional methods to advanced laser cutting technology used by hardware manufacturers. Initially, the lighting industry relied heavily on manual labor and traditional manufacturing techniques such as metalworking and welding. However, with the introduction of advanced technologies like laser cutting, the industry has seen a remarkable shift towards automation and precision manufacturing.Laser cutting technology offers numerous benefits for the lighting industry, including increased efficiency, accuracy, and speed. This technology allows hardware manufacturers to produce complex shapes and designs quickly, reducing production time and costs. In addition, laser cutting produces minimal waste, making it an environmentally friendly option.As the lighting industry continues to evolve, it is likely that we will see even more innovative applications of laser cutting technology. This technology has already revolutionized the way hardware manufacturers produce their products, and it will undoubtedly play a crucial role in shaping the future of the industry. With its ability to streamline production processes and improve product quality, laser cutting is poised to remain a game-changer in the lighting industry for years to come.

In the world of lighting, few elements play as significant a role as hardware. From the simple switches and bulbs to complex fixtures and decorative accents, hardware is the backbone of modern lighting design. And at the heart of every successful lighting project lies the ability to precisely cut and shape these essential components. This is where laser cutting, a state-of-the-art manufacturing technique, comes into play.

The story of modern lighting starts with the introduction of electric lighting in the late 19th century. At first, electrical components were produced using traditional methods like metalworking and soldering. However, as demand for more intricate and customizable designs grew, these methods proved inadequate. It was only with the advent of laser cutting that manufacturers could produce complex shapes and contours with unprecedented precision and speed.

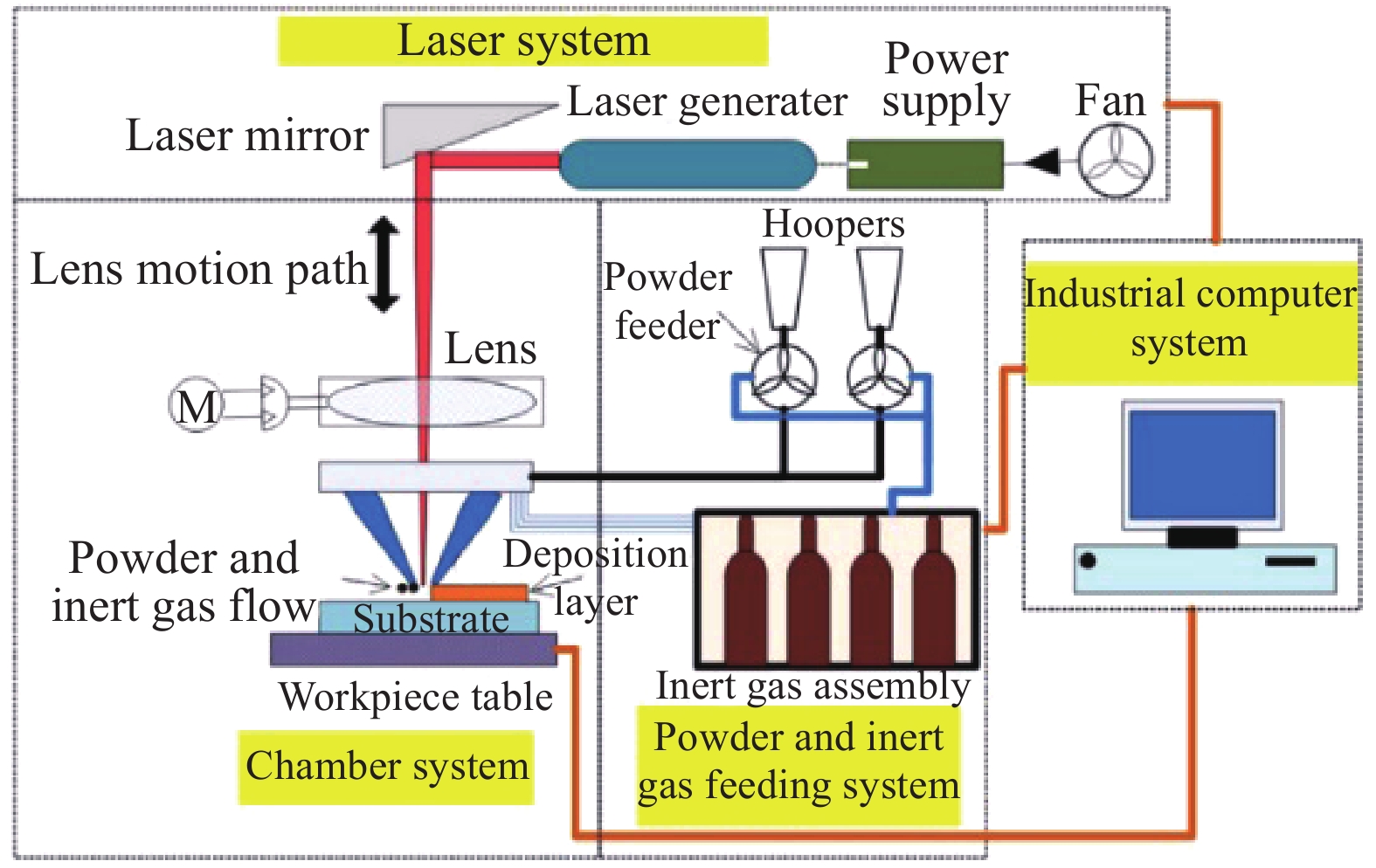

Laser cutting, in essence, uses a high-powered laser beam to melt or vaporize material as it passes through a cutting blade or mask. This process allows engineers and designers to create precise cuts in a variety of metals, including aluminum, copper, and stainless steel. Not only does it offer greater flexibility than traditional cutting methods, but it also results in cleaner cuts with fewer burrs and less waste. In other words, laser cutting opens up a world of possibilities for hardware manufacturers looking to stay ahead of the curve.

One of the key advantages of laser cutting is its ability to produce parts with intricate details and tight tolerances. With traditional techniques like water jet cutting or flame cutting, even the most skilled craftsmen struggle to achieve the level of accuracy required for certain applications. By contrast, laser cutting can handle tasks ranging from simple circles and squares to complex curves and angles, all with pinpoint accuracy. This makes it an ideal choice for applications that require high precision, such as aerospace, automotive, or medical equipment.

Another benefit of laser cutting is its speed and efficiency. Unlike other cutting methods, which often require multiple passes or specialized tools, laser cutting can complete a single pass through the material in seconds. This not only saves time but also reduces labor costs and increases productivity. Additionally, because laser cutting does not involve any chemical processes or thermal effects, it is a cleaner and more environmentally friendly option compared to traditional cutting methods.

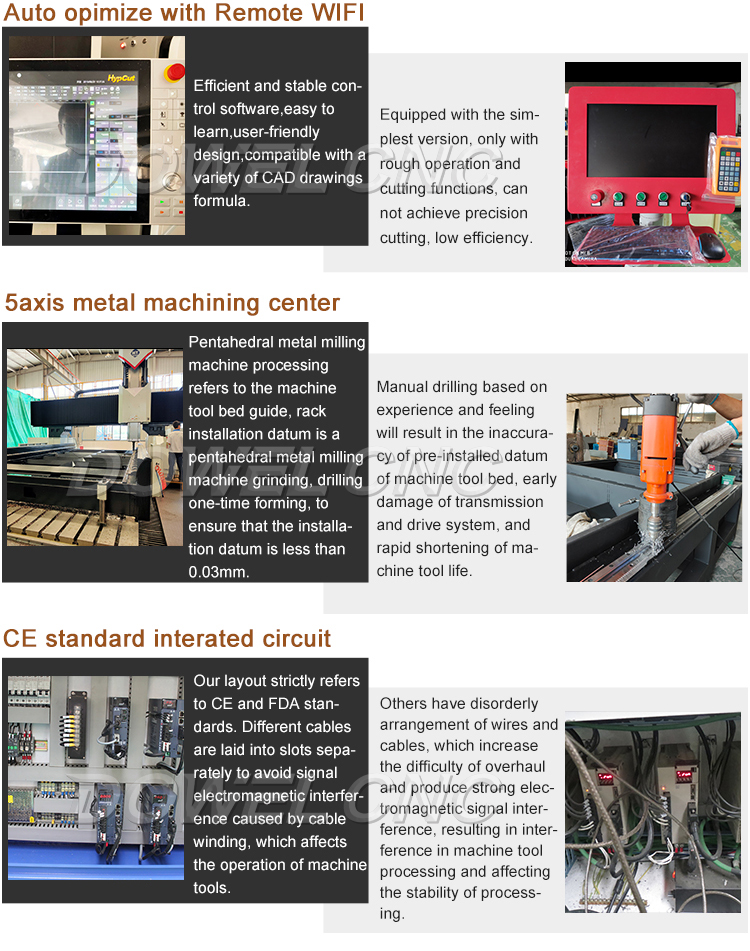

Of course, the adoption of laser cutting in hardware manufacturing is not without its challenges. One major hurdle is the cost of acquiring and maintaining the necessary laser machines and software. These systems can be expensive, and many smaller manufacturers may find them prohibitively costly. However, as technology continues to advance and costs come down, it is likely that laser cutting will become more widespread among hardware manufacturers.

Another challenge is the need for specialized knowledge and training to operate laser cutters safely and effectively. While there are many tutorials and online resources available for learning how to use laser cutters, working with this technology requires a certain level of technical expertise. This means that some small manufacturers may struggle to find qualified staff capable of operating these machines. However, as more companies adopt laser cutting, there is likely to be a growing pool of experienced professionals available to fill this need.

Despite these challenges, the future looks bright for laser cutting in hardware manufacturing. As designers continue to push the boundaries of what's possible with lighting technology, laser cutting will undoubtedly play a central role in meeting their needs. Whether producing sleek modern fixtures or intricate industrial components

Articles related to the knowledge points of this article:

Title: Leading High-End Aluminum Door Hardware Manufacturers in the Market

Hebei Wardrobe Hardware Manufacturers

Xian Tao Hardware Manufacturers

Title: Exploring the World of Hardware Manufacturing in Jinhua: A Guide to Local Suppliers

Xuzhou Environmental Protection Hardware Manufacturers Stock