制作电子五金按需定制

Electronic hardware customization is a service that allows customers to order small quantities of electronic hardware components according to their specific needs. This service has become increasingly popular in recent years due to the rise of the Internet of Things (IoT), which has created a demand for customized electronic hardware products.In this context, it is important to understand the benefits of using electronic hardware customization services. One of the main benefits is that it allows customers to save time and money by avoiding the high costs associated with large-scale production runs. Additionally, customization allows customers to specify their own designs, which can help them create unique and innovative products that meet their specific needs.Moreover, electronic hardware customization services provide customers with a convenient way to obtain the components they need for their projects without having to source them from multiple suppliers. This approach simplifies the procurement process and reduces the risk of errors or discrepancies in the quality of components.In conclusion, electronic hardware customization is a valuable service that can help customers save time and money while creating innovative products that meet their specific needs.

Fabricating Custom Electronic Hardware: A Guide to On-demand Manufacturing

摘要:

本文介绍了电子五金按需定制的概念和流程,包括材料选择、设计、加工和组装等方面的内容,也探讨了电子五金按需定制在各个领域的应用场景和优势,本文旨在帮助读者了解电子五金按需定制的基本知识,从而能够更好地选择适合自己需求的定制服务。

In today's world, with the rise of technology and the demand for customized products, the concept of on-demand manufacturing has become prevalent. One such example is the fabrication of electronic hardware. Electronic hardware is essential in various fields, from computer science to aerospace, and the need for customized electronic hardware is ever-increasing. This article will guide you through the process of making custom electronic hardware using on-demand manufacturing techniques. We will also explore the various applications and benefits of using these techniques. By the end of this article, you will have a clear understanding of how to create your own customized electronic hardware using on-demand manufacturing.

1. On-demand manufacturing

On-demand manufacturing, also known as ‘just-in-time’ manufacturing, is a production strategy that allows businesses to manufacture products only when they are needed, in the quantity required. This approach significantly reduces the cost and time associated with traditional manufacturing methods, as businesses do not have to invest in large inventories or long-term production lines. On-demand manufacturing allows for a high level of customization, as each product can be tailored to meet the specific requirements of the customer. This approach is particularly beneficial for small and medium-sized businesses (SMEs), as it allows them to compete with larger companies by offering customized products at a lower cost.

2. Material selection

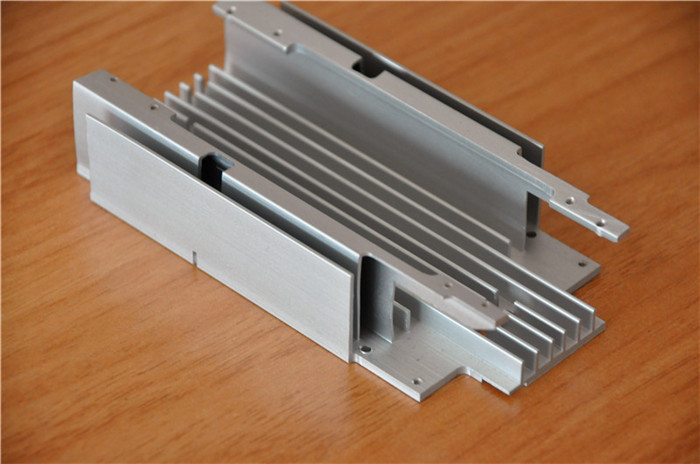

The first step in creating customized electronic hardware is selecting the right materials. Different materials have different properties, such as conductivity, heat resistance, and mechanical strength. It is essential to choose materials that meet the specific requirements of your application. For example, if your electronic hardware needs to withstand high temperatures, you should choose a material with good heat resistance. On the other hand, if your application requires high levels of conductivity, you should opt for materials like copper or aluminum. The material selection process should be done in consultation with your manufacturer, as they will have a wealth of experience in dealing with various materials and can advise you on the best options for your application.

3. Design

Once you have selected the right materials, the next step is to design your electronic hardware. This involves creating a detailed blueprint or CAD (Computer-Aided Design) model of your product. The design process should take into account the shape, size, and functionality of your electronic hardware. It is essential to work closely with your manufacturer during this stage, as they can provide guidance on design best practices and ensure that your design is feasible for manufacturing. Additionally, manufacturers may use their own CAD software or tools to help you create a design that meets your specifications.

4. Processing and Assembly

Once you have a finalized design, it is time to move on to processing and assembly. This involves cutting, bending, and forming the material into its final shape. It is essential to ensure that these processes are carried out accurately to ensure that the final product meets the required specifications. Assembly refers to the process of combining all the individual parts to create the final electronic hardware product. This process should be done with precision to ensure that all parts are properly aligned and secured in their intended positions. Manufacturers typically use specialized equipment and techniques to ensure accurate processing and assembly of electronic hardware components.

5. Applications and benefits

The use of on-demand manufacturing techniques for creating customized electronic hardware offers numerous benefits in various fields. Some of these benefits include:

Cost reduction: On-demand manufacturing allows for significant cost savings as businesses only manufacture products when they are needed, reducing inventory costs and obsolescence risks.

Time savings: Traditional manufacturing methods often involve long lead times due to the need for large-scale production runs. On-demand manufacturing allows for quick turnaround times as each product is made to order.

Customization: This approach allows for a high level of customization, as each product can be tailored to meet the specific requirements of the customer. This approach is particularly beneficial for SMEs, as it allows them to compete with larger companies by offering customized products at a lower cost.

Sustainability: On-demand manufacturing techniques contribute to sustainability by reducing material waste and energy consumption associated with large-scale production runs.

In conclusion, on-demand manufacturing techniques have transformed how we create customized electronic hardware. By understanding these techniques and working closely with manufacturers, businesses can create products that meet their specific needs while reducing costs and environmental impact.

Articles related to the knowledge points of this article:

Title: Customized龙岗五金外壳: Quality and Precision for Your Devices

Title: Customized Metal Hardware and Aluminum Components in Kunming: A Comprehensive Guide

Custom Hardware Brands: A Diverse Range of Options for Your Projects