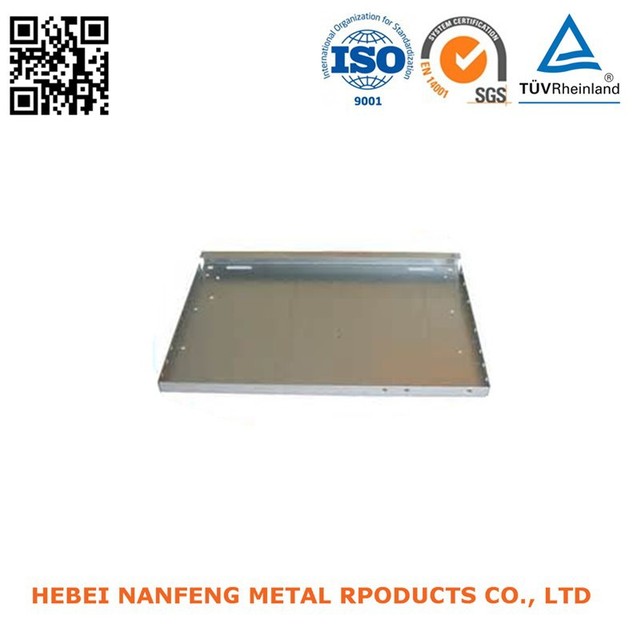

Title: Custom Fabrication of Non-Standard Hardware and Sheet Metal Components

This article outlines the custom fabrication process for non-standard hardware and sheet metal components. It explains the importance of understanding material selection, manufacturing techniques, and assembly processes to produce high-quality, durable products that meet the unique needs of customers. The article also discusses the benefits of using a reliable custom fabrication service to ensure precision, cost-efficiency, and on-time delivery of these components.

Introduction:

In the industrial and manufacturing sectors, there is a growing demand for non-standard hardware and sheet metal components. These components are designed to meet specific requirements and are often tailored to individual applications. As a result, they require a level of customization that can be achieved through the use of advanced manufacturing techniques and materials. This article will explore the process of custom fabrication of non-standard hardware and sheet metal components, emphasizing the importance of using high-quality materials, selecting suitable manufacturing techniques, and meeting customer specifications.

Body:

Firstly, it is essential to use high-quality materials for non-standard hardware and sheet metal components. The materials selected should be able to withstand the conditions in which they will be used, such as temperature, pressure, and chemical exposure. Additionally, the materials should be chosen based on their mechanical properties, thermal conductivity, and electrical resistance. By using high-quality materials, the lifespan of the components can be extended, and their performance can be optimized.

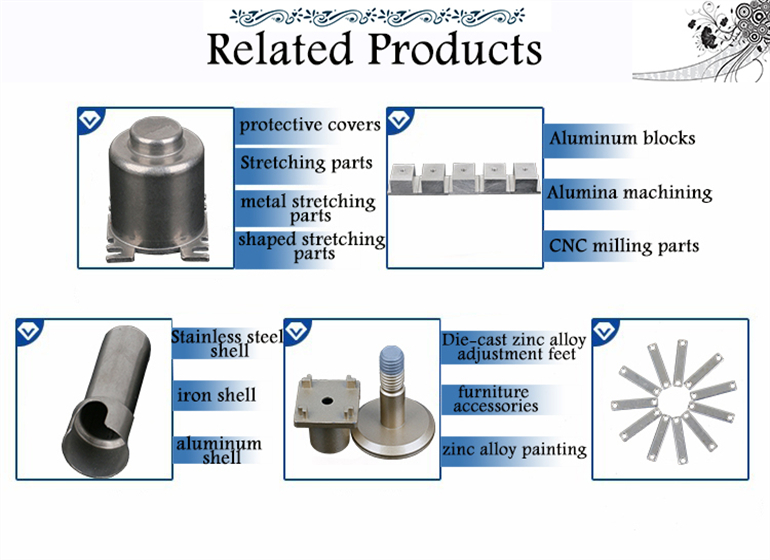

Secondly, it is important to select suitable manufacturing techniques for custom fabrication of non-standard hardware and sheet metal components. The manufacturing process should be chosen based on the complexity of the design, the material being used, and the required tolerance levels. Techniques such as CNC machining, sheet metal forming, welding, and assembly should be selected based on their ability to produce high-quality components that meet the specified requirements. Additionally, using automated manufacturing equipment can help to reduce human error and improve productivity.

Thirdly, it is crucial to meet customer specifications for non-standard hardware and sheet metal components. The components should be designed and manufactured according to the specific requirements provided by the customer. This includes meeting the required dimensions, shapes, and tolerances, as well as ensuring that the components are suitable for their intended application. By meeting customer specifications, it is possible to ensure that the components will perform as expected and contribute to the overall performance of the system in which they are incorporated.

Conclusion:

In conclusion, custom fabrication of non-standard hardware and sheet metal components is a complex but essential process in the industrial and manufacturing sectors. By using high-quality materials, selecting suitable manufacturing techniques, and meeting customer specifications, it is possible to produce components that are tailored to individual applications and meet the demanding requirements of modern industry.

Articles related to the knowledge points of this article:

DIY Custom-Made Wardrobe Hardware for a Seamless Design