CUSTOMIZED PROCESSING OF METAL AND PLASTIC MATERIALS FOR HARDWARE INDUSTRY

The hardware industry is one of the most important manufacturing sectors in the world, offering a wide range of products from simple fasteners to complex machinery. In this industry, the processing of metal and plastic materials is crucial for the production of high-quality hardware products. Customized processing services have become popular in recent years due to the rise in demand for customized hardware products. These services provide flexibility and efficiency in processing, allowing manufacturers to produce products tailored to their specific needs. From material selection to finished product inspection, customized processing ensures that each product meets the desired specifications and quality standards. By offering customized processing services, hardware manufacturers can enhance their productivity, reduce waste, and improve overall profitability.

In the hardware industry, the processing of metal and plastic materials is essential for the manufacture of various products. This article will explore the customized processing of these materials to meet the demands of hardware manufacturers. We will discuss the importance of material selection, processing techniques, and product quality in this context.

Metal materials are widely used in hardware industry due to their mechanical properties, thermal stability, and electrical conductivity. Customized processing of metal materials allows manufacturers to tailor the properties of the material to meet specific product requirements. For example, some products may require high strength and durability, while others may need good electrical conductivity. By selecting the appropriate metal material and processing techniques, manufacturers can ensure that their products meet these requirements.

Plastic materials have also become important in hardware industry due to their lightweight, good insulation properties, and resistance to corrosion. Customized processing of plastic materials allows manufacturers to adjust the properties of the material to meet the demands of their products. For example, some products may require high heat resistance, while others may need good mechanical properties. By selecting the appropriate plastic material and processing techniques, manufacturers can achieve the desired product characteristics.

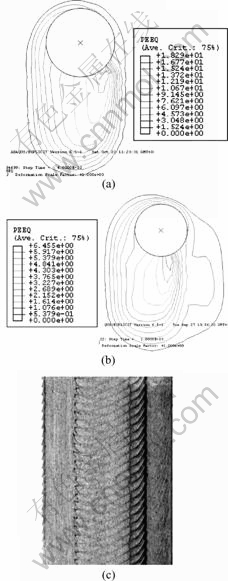

In addition to material selection, processing techniques are crucial for achieving high-quality products. Customized processing techniques can help manufacturers enhance the mechanical properties, thermal stability, and electrical conductivity of their products. For example, some manufacturers may use advanced machining techniques to achieve high precision and smooth surfaces on their metal components. Others may employ plastic molding techniques to produce complex shapes and structures in plastic materials.

Finally, product quality is essential for hardware manufacturers to ensure that their products meet customer expectations. Customized processing allows manufacturers to tailor the properties of their products to meet specific customer requirements. By selecting the appropriate material and processing techniques, manufacturers can ensure that their products have high mechanical strength, thermal stability, and electrical conductivity. This approach also allows manufacturers to improve their product reliability and reduce warranty claims.

In conclusion, customized processing of metal and plastic materials is essential for hardware manufacturers to meet the demands of their customers. By selecting the appropriate materials and processing techniques, manufacturers can ensure that their products have high quality and meet customer expectations.

Articles related to the knowledge points of this article:

Customized Hardware Equipment Solutions

Title: Custom Processing and Printing of Metals Hardware Ink in Meizhou - An Experts Guide

Title: Customized Automobile Hardware Handle in Heyuan