Title: Non-standard Hardware Fittings: An Introduction to Their Uses and Benefits

This article introduces non-standard hardware fittings and explains their uses and benefits. Non-standard fittings are commonly used in plumbing, electrical, and mechanical systems, providing a convenient and cost-effective solution for connecting and adapting various components. These fittings are designed to fit specific applications, providing a customized solution for each project. By using non-standard fittings, engineers and technicians can save time and money on installation, maintenance, and replacement costs. Additionally, these fittings are often more reliable and durable than standard fittings, providing a longer service life.

In the world of manufacturing, non-standard hardware fittings have become an integral part of various industrial applications. These fittings, often overlooked in favor of their standard counterparts, possess unique qualities that make them highly advantageous in specific scenarios. By understanding the benefits and uses of non-standard hardware fittings, engineers and designers can unlock their potential to enhance product performance and efficiency.

What are Non-standard Hardware Fittings?

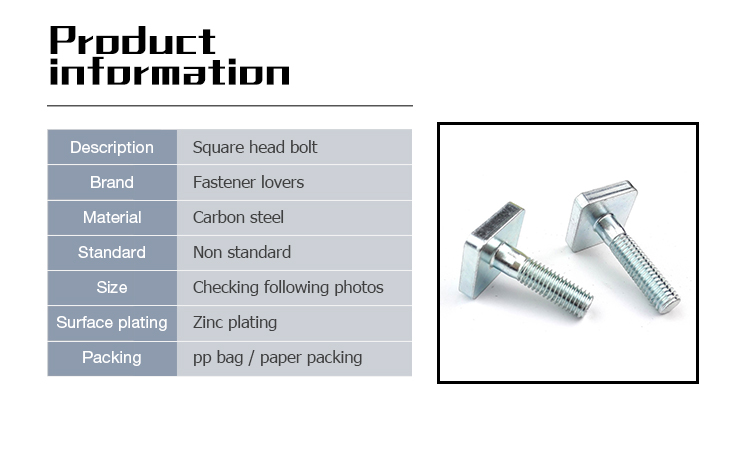

Non-standard hardware fittings are exactly what their name implies: hardware components that deviate from traditional standards in terms of shape, size, or material composition. While standard fittings are typically designed to meet the general needs of an industry, non-standard fittings are tailored to meet the unique requirements of specific applications. This approach allows for a higher level of customization and allows designers to optimize their products for specific use cases.

Uses of Non-standard Hardware Fittings

1、High-Performance Applications: In industries where performance is paramount, non-standard hardware fittings are commonly used. For example, in aerospace, automotive, and high-tech equipment manufacturing, these fittings are often employed to ensure optimal performance under extreme conditions. By customizing the shape, size, and material composition, engineers can create fittings that are stronger, lighter, and more durable than standard options.

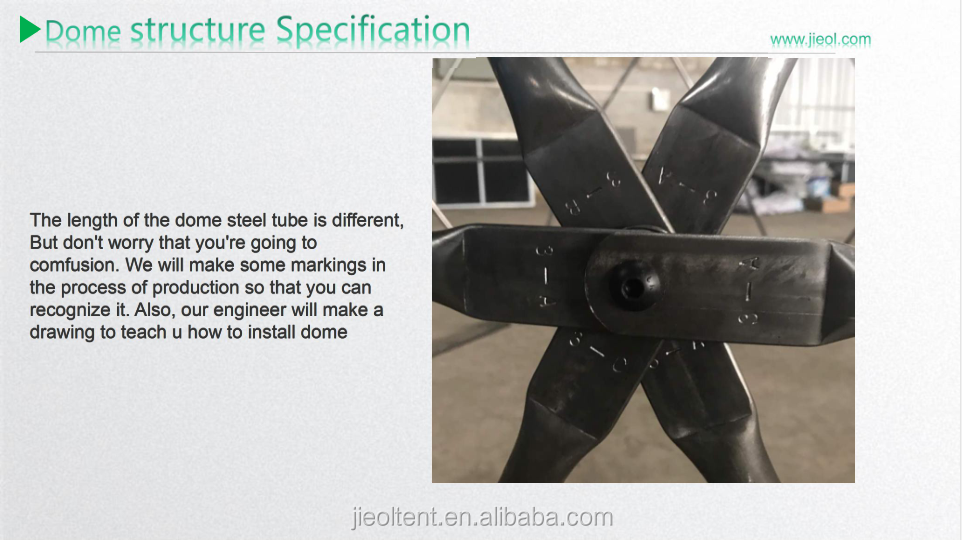

2、Complex Assembly Processes: In many assembly processes, non-standard hardware fittings play a crucial role. They may be used to connect different components together, providing a secure and reliable connection that can withstand the rigors of repeated use. Additionally, these fittings can be designed to accommodate complex shapes or irregular surfaces, making them ideal for challenging assembly scenarios.

3、Cost Optimization: While standard hardware fittings are typically mass produced using standard materials and processes, non-standard fittings can be optimized for cost. By using unique materials or manufacturing techniques, engineers can create fittings that are both cost-effective and meet the specific needs of an application. This approach allows for a higher level of flexibility in terms of material selection and manufacturing process, leading to a more cost-effective solution.

Benefits of Non-standard Hardware Fittings

1、Enhanced Performance: Non-standard hardware fittings often offer superior performance compared to their standard counterparts. By customizing the shape, size, and material composition, engineers can create fittings that are stronger, lighter, and more durable. This approach allows for a higher level of optimization, leading to improved product performance.

2、Greater Flexibility: One of the biggest benefits of non-standard hardware fittings is their flexibility. Unlike standard fittings, which are designed to meet the general needs of an industry, non-standard fittings can be tailored to meet the unique requirements of specific applications. This approach allows for a higher level of customization and allows designers to optimize their products for specific use cases.

3、Cost Savings: While non-standard hardware fittings may have a higher upfront cost compared to standard fittings, they often offer significant cost savings in the long run. By using unique materials or manufacturing techniques, engineers can create fittings that are both cost-effective and meet the specific needs of an application. This approach allows for a more efficient use of materials and manufacturing resources, leading to a more cost-effective solution.

In conclusion, non-standard hardware fittings offer a unique and valuable solution for industries that require customized hardware components. By understanding the benefits and uses of these fittings, engineers and designers can unlock their potential to enhance product performance and efficiency. Whether it is high-performance applications, complex assembly processes, or cost optimization, non-standard hardware fittings provide a tailored solution that meets the specific needs of each application.

Articles related to the knowledge points of this article:

The Development of Leather and Hardware Accessories for Boxes and Bags