HARDWARE ACCESSORIES SPECIFICATIONS

This document outlines the specifications for hardware accessories that are compatible with a specific product or system. It provides detailed information about the different hardware components, including their physical dimensions, electrical characteristics, and mechanical properties. The goal is to ensure that the hardware accessories meet the performance and reliability standards required for the intended application. By referring to these specifications, users can identify the correct hardware accessories for their specific needs and ensure compatibility with the main product or system.

In the field of mechanical engineering, hardware accessories play a crucial role. They are the components that connect, support, and facilitate the functioning of various mechanical systems. Therefore, it is essential to have a detailed understanding of their specifications to ensure their compatibility, performance, and longevity. This article will explore the specifications of hardware accessories commonly used in mechanical engineering.

1. Fasteners

Fasteners are hardware accessories that are used to connect two or more components together. They are available in a wide range of shapes and sizes to suit different applications. Some common fasteners include bolts, screws, nails, and rivets.

Bolts are threaded fasteners commonly used to connect metal components. They have a male thread that engages with a female thread in the component being connected. The specifications of bolts include their diameter, length, thread type, and material composition.

Screws are also threaded fasteners but are typically smaller than bolts and are often used to connect wooden or plastic components. They have a single thread on their shank that engages with a corresponding female thread in the component being connected. The specifications of screws include their diameter, length, thread type, and material composition.

Nails are non-threaded fasteners commonly used to connect wooden components. They have a smooth shank and are driven into the component being connected using a hammer or nail gun. The specifications of nails include their diameter, length, material composition, and type (e.g., common nails, finish nails, brad nails).

Rivets are non-threaded fasteners that are used to connect metal components. They have a male thread on one end that engages with a female thread on the other end to form a strong connection. The specifications of rivets include their diameter, length, material composition, and type (e.g., solid rivets, hollow rivets).

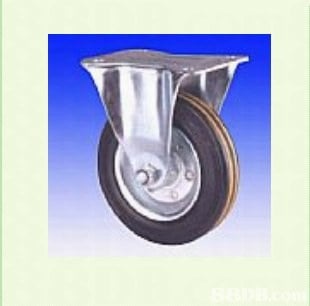

2. Bearings

Bearings are hardware accessories that support rotational motion in mechanical systems. They reduce friction and wear between moving parts, ensuring smooth and efficient operation. Common bearings include ball bearings, roller bearings, and plain bearings.

Ball bearings consist of two concentric rings with a number of steel balls positioned between them. The outer ring is stationary while the inner ring rotates, creating a smooth rolling motion between the balls and the rings. The specifications of ball bearings include their diameter, material composition, type (e.g., deep groove ball bearings, angular contact ball bearings), and load capacity.

Roller bearings are similar to ball bearings but use cylindrical rollers instead of steel balls. They are typically used in applications where heavy loads or high speeds are encountered. The specifications of roller bearings include their diameter, length, material composition, type (e.g., single row roller bearings, double row roller bearings), and load capacity.

Plain bearings are non-rotating bearings that support axial or radial loads in mechanical systems. They consist of two metal surfaces separated by a thin film of oil or grease to reduce friction. The specifications of plain bearings include their diameter, material composition, type (e.g., bronze plain bearings, steel plain bearings), and load capacity.

3. Gaskets

Gaskets are thin sealing devices made from soft materials like rubber, silicone, or graphite. They are used to fill gaps between two surfaces to prevent leakage of fluids or gases. The specifications of gaskets include their thickness, material composition, type (e.g., flat gasket, corrugated gasket), and operating temperature range.

4. Hoses and Tubes

Hoses and tubes are flexible containers used to transport fluids or gases in mechanical systems. They are made from a variety of materials like rubber, plastic, or metal and come in different shapes and sizes to suit different applications. The specifications of hoses and tubes include their diameter, length, material composition, type (e.g., pressure hose, suction hose), and operating temperature range.

5. Sealants

Sealants are substances used to fill gaps or joints in mechanical systems to prevent leakage of fluids or gases. They are typically applied in liquid form and then cure to form a solid sealant layer. Common sealants include silicone sealant, acrylic sealant, and polyurethane sealant. The specifications of sealants include their type (e.g., waterproof sealant, high-temperature sealant), material composition, and operating temperature range.

In conclusion, hardware accessories play a crucial role in mechanical engineering applications by providing the necessary connections, support, and sealing functions for smooth and efficient operation of mechanical systems. Understanding their specifications is essential for selecting the right hardware accessories for specific applications while considering factors like compatibility, performance, and longevity.

Articles related to the knowledge points of this article:

Wenzhou Hardware Accessories: The Heart of Machinery

Title: Recycling of Hardware Accessories: A Sustainable Solution for Waste Management

Title: Categorization of Jiangyin Industrial Metal Parts Processing

Windows and Doors Hardware Accessories: A Comprehensive Guide