Title: Custom Metal Fabrication for a Range of Applications

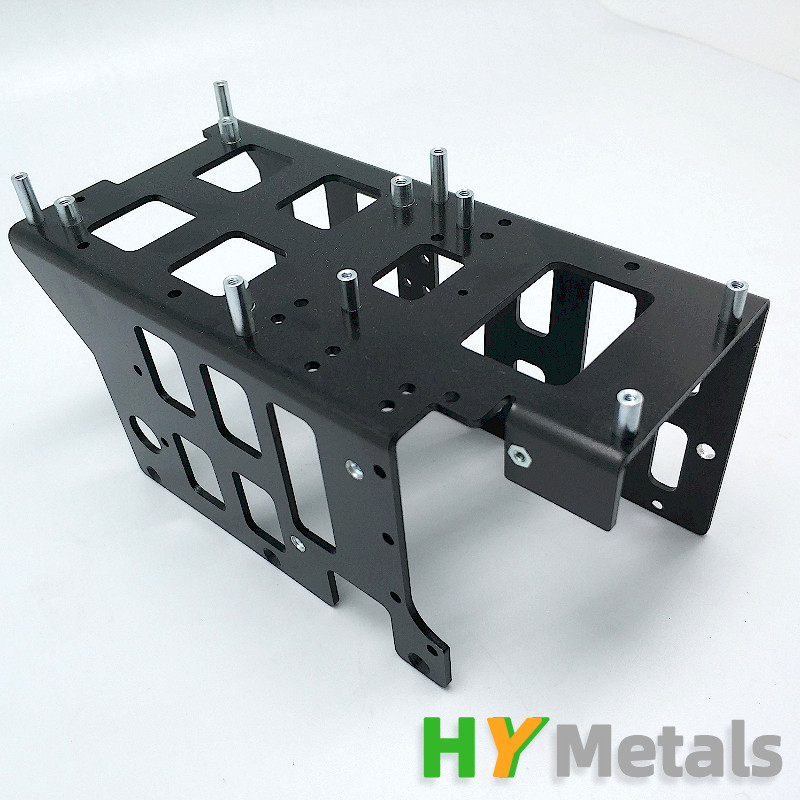

Custom Metal Fabrication for a Range of Applications Custom metal fabrication is a process that involves cutting, shaping, and assembling metal components to create a range of products and applications. This process can be used to produce parts for various industries, including automotive, aerospace, medical, and more. Custom metal fabrication allows for precision manufacturing of complex shapes and designs that may not be possible using traditional machining techniques. In addition, it provides cost-effective solutions for small to large-scale production runs. By utilizing advanced technology and skilled craftsmen, custom metal fabricators can create products that meet the highest quality standards. Whether it’s for a new automotive part, a medical device, or an aerospace component, custom metal fabrication provides the versatility and precision necessary to meet the demands of today’s manufacturing industry.

Custom metal fabrication is a process that involves cutting, shaping, and assembling metal materials to create finished products. This process is used in various industries, including automotive, aerospace, and medical, to name a few. In this article, we will explore the world of custom metal fabrication and how it contributes to the success of many businesses.

Cutting metal is the first step in the fabrication process. This step involves using a variety of tools and machines to cut the metal into the desired shapes and sizes. The cutting process can be done manually or with the help of machines, depending on the complexity of the design and the volume of the production. Once the metal is cut, it is ready for the next step, which is shaping.

Shaping is the process of bending, folding, or otherwise manipulating the metal to achieve the desired shape. This process can be done using various techniques, including hammering, press braking, and laser bending. The choice of technique depends on the type of metal being used and the complexity of the shape. Once the metal is shaped, it can be assembled with other pieces to create a finished product.

Custom metal fabrication is used in a wide range of applications. One example is the automotive industry. Many car manufacturers use custom metal fabrication to create the body panels, frames, and other components of their vehicles. Another example is the aerospace industry, which uses custom metal fabrication to create aircraft parts and components. The medical industry also uses custom metal fabrication to create surgical instruments, dental implants, and other medical devices.

In addition to these industries, custom metal fabrication is also used in many other sectors, including construction, transportation, and agriculture. Construction companies use custom metal fabrication to create structural supports, railings, and other components of buildings. Transportation companies use it to create railway tracks, bridges, and other transportation infrastructure. And agriculture uses it to create agricultural machinery and equipment.

Custom metal fabrication plays a crucial role in these industries and applications because it allows businesses to create products that meet their specific needs and requirements. It allows for a high level of customization and precision, which can be essential for certain applications. For example, in the medical industry, surgical instruments must be precision-crafted to ensure they are effective and safe for use in human bodies. Custom metal fabrication allows manufacturers to achieve this precision and quality.

Moreover, custom metal fabrication can help businesses save time and money by reducing the need for manual labor and increasing productivity through automation. Many modern custom metal fabricators use advanced technology to automate many of the fabrication processes, which not only speeds up production but also reduces human error. This can be particularly beneficial for businesses that require high volumes of products or those that operate on tight deadlines.

In conclusion, custom metal fabrication is a crucial process for many industries and applications. It allows businesses to create products that meet their specific needs and requirements, saving time and money in the process. By understanding the world of custom metal fabrication, businesses can better utilize this process to enhance their operations and achieve their goals.

Articles related to the knowledge points of this article:

Title: An Overview of the Top Custom Hardware Brands in Anhui Province

Title: Customizing Hardware Baskets in Zhaoqing: A Comprehensive Guide

Title: Customized Metal Hook Production Solutions for Industrial Applications

Title: Shandong Hardware and Sheet Metal Processing Customization