Flange Nuts Wholesale: A Guide to Selecting and Purchasing

This guide provides an overview of flange nuts wholesale, including important considerations for selecting and purchasing these fasteners. Flange nuts are a type of nut with a built-in flange that allows them to be used in a variety of applications. They are commonly used in mechanical, aerospace, and automotive industries. When selecting flange nuts, it is important to consider factors such as material, size, and shape. For example, stainless steel flange nuts are commonly used in applications that require high resistance to corrosion and high temperatures. On the other hand, aluminum flange nuts are lightweight and commonly used in automotive applications. Size and shape also vary depending on the application. Finally, it is important to find a reputable supplier who can provide high-quality flange nuts at a reasonable price. By following these guidelines, you can ensure that you select and purchase the right flange nuts for your application.

Flange nuts, also known as flange bolts, are a type of fastener with a unique design that allows them to provide support and withstand high levels of stress. These nuts are commonly used in various applications, including automotive, aerospace, and construction, due to their ability to resist corrosion and provide a strong, secure connection.

What are flange nuts?

Flange nuts are bolts that have a flange on one end, which is typically perpendicular to the axis of the bolt. The flange serves as a bearing surface and allows the nut to distribute the load more evenly over a larger area, reducing stress concentrations. These nuts are often made from stainless steel or other high-performance materials that can withstand harsh environments and are resistant to corrosion.

Types of flange nuts

There are several types of flange nuts available, each designed for specific applications. Common types include:

Standard flange nuts: These have a plain or slightly threaded shank and are suitable for general use in a range of applications.

High-performance flange nuts: These are designed for applications that require high strength and resistance to corrosion. They are often made from stainless steel or other specialty materials.

Threaded flange nuts: These have a threaded shank that allows for greater flexibility in installation and removal. They are commonly used in applications where the nut needs to be easily replaced or adjusted.

Selecting flange nuts

When selecting flange nuts, it is important to consider the following factors:

Material: The material from which the flange nuts are made is crucial. Stainless steel is commonly used in high-performance applications due to its resistance to corrosion and high strength. However, standard applications may use carbon steel or other materials depending on the specific requirements.

Size and shape: The size and shape of the flange nuts also need to be considered. Different shapes, such as hex, square, or round, have their own benefits and are designed for specific applications. Hex-shaped flange nuts, for example, are commonly used in applications where easy access to the bolt is needed during installation or removal.

Thread type: The type of thread on the flange nuts is important. Common thread types include standard coarse threads for general use and fine threads for precision applications. The thread type should match the application's requirements in terms of load-bearing capacity and ease of installation.

Surface treatment: Flange nuts may undergo surface treatments such as coating or plating to enhance their corrosion resistance or load-bearing capacity. These treatments should be selected based on the environmental conditions and expected usage of the bolts.

Purchasing flange nuts

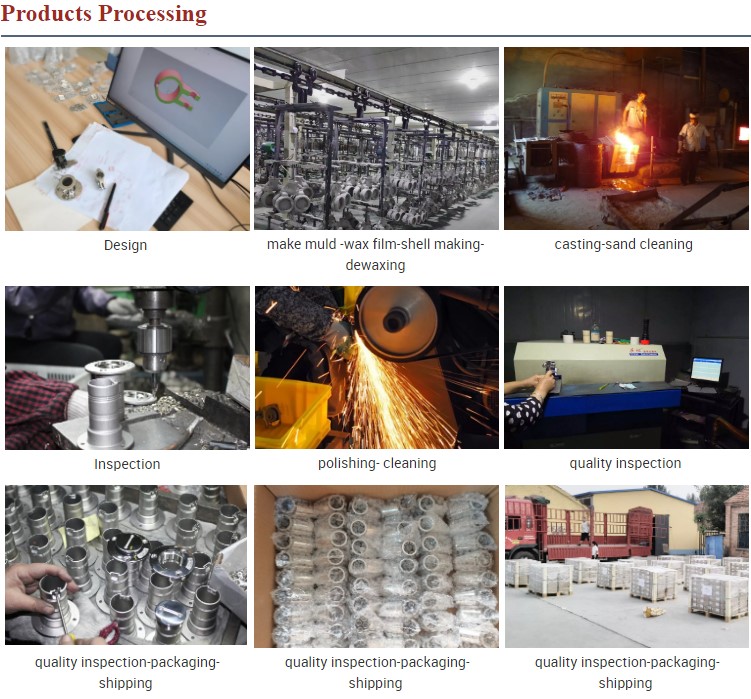

When purchasing flange nuts, it is essential to specify the exact requirements of the bolts, including material, size, shape, thread type, and surface treatment. This information can be provided to a supplier or manufacturer who will then produce the bolts according to the specified requirements. It is important to choose a reliable supplier with a good reputation for producing high-quality bolts that meet or exceed industry standards. Additionally, purchasing bolts from a trusted supplier ensures consistency in quality and performance, which is crucial for any application that relies on these fasteners.

Articles related to the knowledge points of this article:

Wholesale Hardware Piping Pictures: A Visual Guide to Piping Materials and Fittings

Handrail Gate Control Hardware Wholesale

Title: Exploring the Shandong Linyi Hardware Wholesale Market: A Hub of Trade and Innovation