Title: Exploring the Excellence of Foshan Sanitary Ware Hardware Manufacturing: A Masterpiece in Chinese Metalwork Industry

Foshan, a city located in southern China's Guangdong Province, has long been renowned for its exceptional craftsmanship in metalwork, particularly in the field of sanitary ware hardware manufacturing. This city is home to some of the most skilled artisans and manufacturers in this industry, who have perfected the art of creating high-quality sanitary ware hardware over the years. Their expertise lies in their ability to combine traditional Chinese techniques with modern technology and innovation to produce products that are not only functional but also aesthetically pleasing. The precision and attention to detail that these craftsmen bring to every piece they create make Foshan sanitary ware hardware manufacturing a masterpiece in China's metalwork industry. From the intricate designs and patterns to the durable materials used, every aspect of Foshan's sanitary ware hardware is a testament to the excellence and dedication of its creators. In today's world of fast-paced consumerism and mass production, Foshan's commitment to preserving the art of handcrafted sanitary ware hardware is more important than ever. It is a shining example of how traditional skills can be passed down through generations and still remain relevant and valuable in the modern era. As such, Foshan's sanitary ware hardware manufacturing is not just an industry; it is a cultural treasure that deserves recognition and appreciation from people all around the world.

Introduction:

Foshan, a city located in Guangdong Province in southern China, has been renowned for its exceptional manufacturing capabilities in various industries. Among them, the sanitary ware hardware manufacturing sector stands out as a prime example of Chinese metalworking prowess. With a history spanning several decades, Foshan has established itself as a leading producer of high-quality sanitary ware hardware, including铜五金制品, catering to the needs of global consumers. This article aims to delve into the fascinating world of Foshan sanitary ware hardware manufacturing, highlighting its evolution, production processes, and the role it plays in shaping the future of this dynamic industry.

I. The Evolution of Foshan Sanitary Ware Hardware Manufacturing

A. Early Beginnings: Foshan's roots can be traced back to the late 1970s when the city began to witness an influx of migrant workers from neighboring provinces seeking employment in the newly emerging manufacturing sector.

B. Formation of Sanitary Ware Hardware Manufacturers Association: In response to the growing demand for sanitary ware hardware products, Foshan's government established the Sanitary Ware Hardware Manufacturers Association in the early 1980s, which served as a platform for local businesses to network, share knowledge, and collaborate on technological advancements.

C. Technological Innovations and Product Development: Over the years, Foshan's sanitary ware hardware manufacturers have continuously invested in research and development, embracing cutting-edge technologies such as automation, robotics, and artificial intelligence to enhance product quality, efficiency, and competitiveness. Today, Foshan's sanitary ware hardware industry boasts a diverse range of products, including but not limited to:

1、Faucets and valves

2、Showerheads and valves

3、Toilet seats and bowls

4、Bathtub faucets and handles

5、Kitchen and bathroom cabinets

6、Lighting fixtures and switches

7、Door locks and handles

8、Pipe fittings and connectors

9、Home appliances and electronic devices (e.g., washing machines, dishwashers) that feature stainless steel or copper hardware.

II. The Production Processes in Foshan Sanitary Ware Hardware Manufacturing

A. Design and Engineering: The first step in the production process involves designing and engineering custom hardware solutions based on customers' requirements and preferences. This requires a skilled workforce with expertise in both technical and artistic aspects of metalwork, ensuring that each product meets both functional and aesthetic standards.

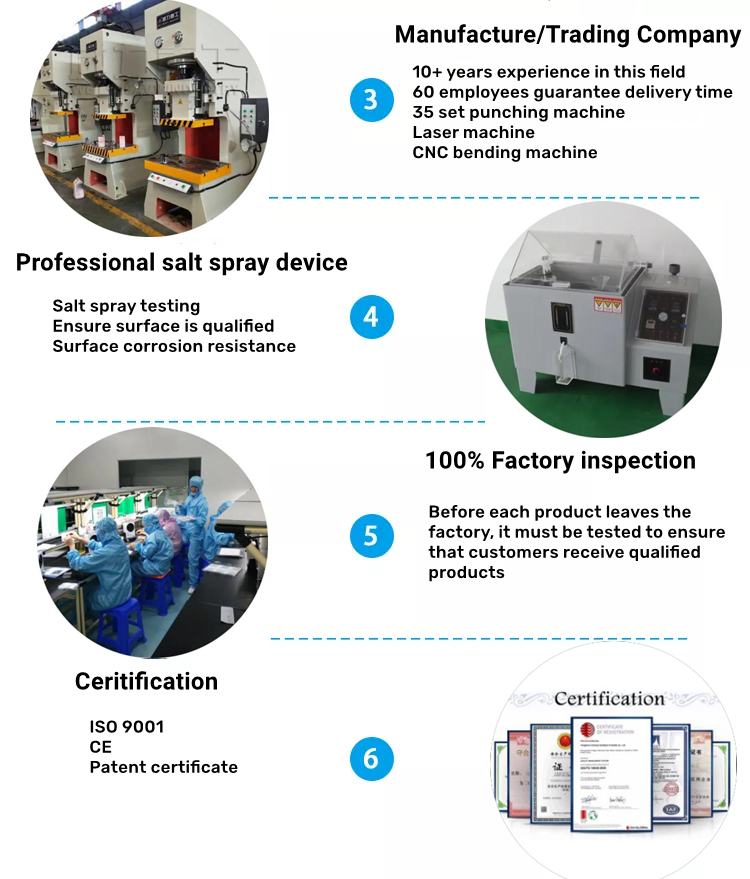

B. Material Sourcing and Quality Control: Foshan's sanitary ware hardware manufacturers source high-quality raw materials from well-established suppliers worldwide, ensuring consistency and reliability in product performance. The manufacturers also implement rigorous quality control measures throughout the production process, including material testing, surface treatment, assembly verification, and final inspection to ensure that each product meets stringent international standards.

C. Manufacturing Techniques: The manufacturing process involves various techniques tailored to different types of hardware products. Some commonly used methods include:

1、Casting: This technique involves pouring molten metal into molds to create solid components that can be shaped into desired designs. Casting is often applied to manufacture large volumes of parts with consistent quality characteristics.

2、Forging: This method involves compressing heated metal into shape using hammers or other mechanical forces. Forging is particularly suitable for producing complex shapes or intricate details that cannot be achieved through other techniques such as casting or machining.

3、Machining: Machine tools such as lathes, milling machines, and CNC routers are used to cut, shape, or engrave metal parts according to predefined specifications. Machining is essential for producing precision components with smooth surfaces and tight tolerances required for high-end hardware products.

D. Surface Treatment: To enhance product aesthetics and durability, Foshan's sanitary ware hardware manufacturers apply various surface treatments such as polishing, painting, electroplating, or coating using advanced technologies like PVD (Physical Vapor Deposition) or sandblasting. These treatments not only add visual appeal but also protect the metal against corrosion, wear & tear, and environmental damage.

III. The Role of Foshan Sanitary Ware Hardware Manufacturing in Shaping the Future of Chinese Metalworking Industry

A. Global Export Market Presence: With its exceptional quality standards and advanced manufacturing processes

Articles related to the knowledge points of this article:

Title: The Art of Craftmanship: An In-Depth Look into High-End Single Chair Furniture Manufacturer

Manual Hardware Manufacturers Ranking

Dongguan Modern Hardware Manufacturer’s Stock

Technical Support for Hardware Manufacturers: Importance and Challenges