CUSTOM METAL FABRICATION: A DETAILED GUIDE

This detailed guide outlines the process of custom metal fabrication, from design to production. It explains the different techniques and processes used to fabricate metal components, including cutting, bending, welding, and finishing. The guide also highlights the importance of material selection, as well as the consideration of cost and time constraints. It provides a clear understanding of the entire metal fabrication process, essential for anyone looking to have custom metal components made.

Introduction:

Custom metal fabrication is a process of creating metal components and structures that are tailored to meet specific requirements. This process involves cutting, bending, welding, and finishing of metals to achieve the desired shape, size, and appearance. Custom metal fabrication is widely used in various industries such as automotive, aerospace, marine, and construction.

What is Custom Metal Fabrication?

Custom metal fabrication refers to the process of creating metal parts and structures that are not produced in standard sizes or shapes. It involves cutting, bending, welding, and finishing of metals to achieve the desired shape, size, and appearance. Custom metal fabrication allows for the creation of unique designs and complex shapes that may not be possible using standard manufacturing techniques.

Why Use Custom Metal Fabrication?

There are several benefits to using custom metal fabrication:

1、Tailored to Specific Requirements: Custom metal fabrication allows for the creation of metal components that meet specific requirements. Whether it is a unique design, complex shape, or non-standard size, custom fabrication allows for the production of parts that are tailored to meet individual needs.

2、Cost-Effective: In many cases, custom metal fabrication can be more cost-effective than standard manufacturing techniques. By creating parts in small quantities or using unconventional materials, custom fabrication can help reduce overall production costs.

3、High Quality Standards: Custom metal fabrication often requires a high level of precision and quality control. This ensures that each part meets the desired specifications and standards, resulting in a high-quality product.

4、Unique Design Capabilities: Custom metal fabrication allows for the creation of unique designs and complex shapes that may not be possible using standard manufacturing techniques. This allows for a great deal of creativity and design flexibility.

5、Short Lead Times: In many cases, custom metal fabrication can be completed in a relatively short time frame. This allows for quick response to unexpected demand or last-minute changes to designs.

How Does Custom Metal Fabrication Work?

The process of custom metal fabrication typically involves the following steps:

1、Design: The first step is to create a design for the desired metal component or structure. This can be done using computer-aided design (CAD) software or by hand. The design should specify the shape, size, material, and any other important details.

2、Material Selection: Next, the appropriate material for the desired application is selected. Common materials used in custom metal fabrication include steel, aluminum, stainless steel, and titanium. Each material has its own unique properties and advantages, so the selection should be based on the specific requirements of the application.

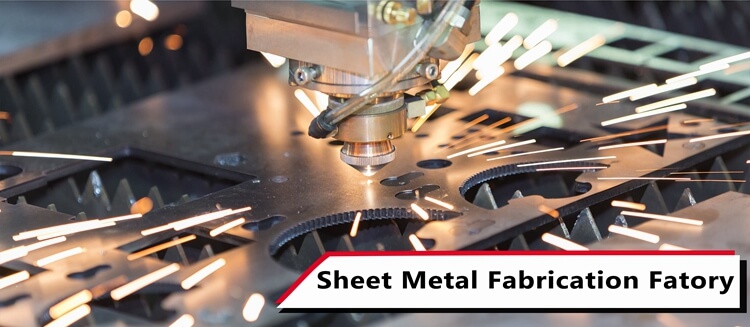

3、Cutting: Once the material is selected, it is cut to the desired shape using a variety of cutting techniques such as plasma cutting, laser cutting, or waterjet cutting. These techniques allow for precise cutting of complex shapes and designs.

4、Bending: The cut material is then bent to form the desired angles and shapes. Bending can be done using press brakes, bending machines, or hand tools depending on the complexity of the shape and material being used.

5、Welding: The bent pieces are then welded together to form the final structure or component. Welding techniques such as arc welding, laser welding, or electron beam welding are commonly used in custom metal fabrication.

6、Finishing: The final step is to finish the fabricated part to achieve the desired appearance and surface quality. This may involve sanding, polishing, painting, or other finishing techniques depending on the specific requirements of the application.

Conclusion:

Custom metal fabrication is a versatile and cost-effective way to create metal components and structures that meet specific requirements. By understanding the process involved in custom metal fabrication, it is possible to streamline production, reduce costs, and create high-quality products that meet individual needs.

Articles related to the knowledge points of this article:

Custom Hardware Charging in Beijing

Title: Customized Hardware Solutions in Hebei Province: Tailor-Made Products for Your Specific Needs

Custom Tailored Jackets for the Elite: A Look into the World of Hardware and Clothing

Title: Crafting Custom Hardware Solutions for the Hainan Region