Title: Precision Hardware Production for Furniture Batch Manufacturing

Precision hardware production has become a crucial aspect of furniture batch manufacturing due to the increasing demand for high-quality and customized products. The use of advanced machinery, such as CNC machines and robotics, has enabled manufacturers to produce precise components with minimal errors. These technologies allow for faster production times and greater accuracy in measurements, ensuring that each piece of furniture meets the required specifications. Additionally, precision hardware production helps to reduce waste and optimize material usage, leading to cost savings for furniture manufacturers. With the continued advancements in technology, it is likely that precision hardware production will become even more prevalent in the furniture industry, allowing for greater flexibility and customization in the manufacturing process. As a result, furniture manufacturers who invest in precision hardware production will be able to stay competitive in an increasingly globalized marketplace.

In the world of furniture manufacturing, precision hardware is a critical component that determines the durability, functionality, and aesthetic appeal of the final product. From hinges and knobs to screws and brackets, these small but significant details can make all the difference in creating a high-quality piece of furniture. That's why precision hardware production for furniture batch manufacturing must be done with the utmost care and attention to detail.

The Importance of Precision Hardware in Furniture Manufacturing

Precision hardware plays a crucial role in the construction of furniture. It allows for smooth operation and proper alignment of components, ensuring that the furniture functions as intended. Additionally, precision hardware can enhance the overall appearance of the furniture, making it look more stylish and polished.

However, not all hardware is created equal. The hardware used in furniture manufacturing must be of the highest quality to ensure durability and longevity. This means selecting materials that are strong, resistant to wear and tear, and able to withstand frequent use over time.

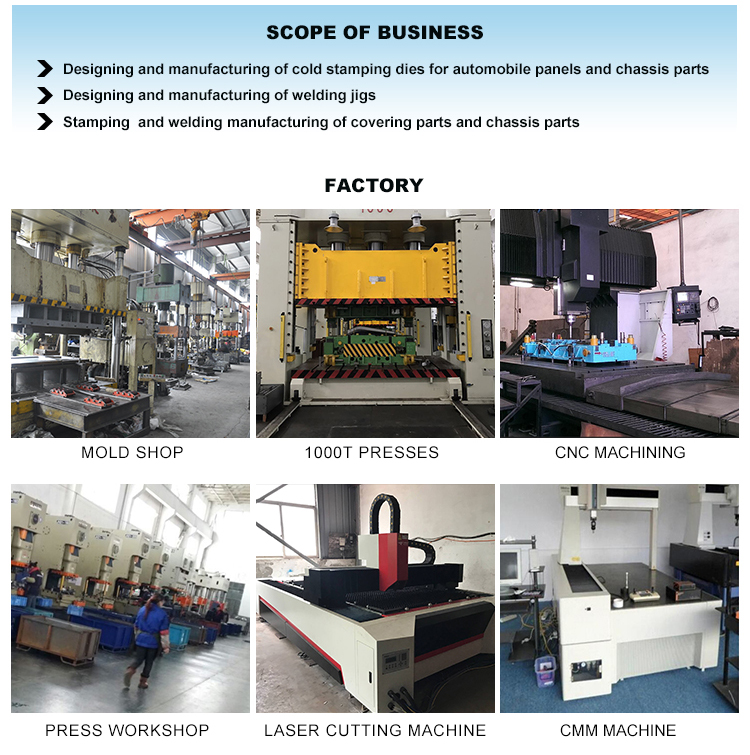

The Process of Precision Hardware Production for Furniture Batch Manufacturing

The process of precision hardware production for furniture batch manufacturing involves several steps. First, the manufacturer must design the hardware components to meet the specific requirements of the furniture project. This includes determining the size, shape, and material of each component based on the needs of the furniture.

Next, the manufacturer must manufacture the hardware components using advanced machinery and tools. This typically involves programming specialized machines to produce complex shapes and sizes of hardware components with precision and accuracy. In some cases, custom designs may require additional time and resources to produce.

Once the hardware components have been manufactured, they must be carefully inspected to ensure that they meet the required quality standards. This may involve testing the components for strength, durability, and functionality using specialized equipment. If any components fail to meet these standards, they may need to be reworked or replaced.

Finally, the manufactured hardware components are packaged and prepared for shipment to the furniture manufacturer. This may involve labeling each package with relevant information such as part number, size, and material.

The Benefits of Precision Hardware Production for Furniture Batch Manufacturing

There are several benefits to precision hardware production for furniture batch manufacturing. First, it ensures that the furniture is built to high standards of quality and durability. This helps to extend the lifespan of the furniture and reduce the need for frequent repairs or replacements.

Additionally, precision hardware production for furniture batch manufacturing can help to reduce costs by minimizing waste and optimizing resource utilization. By producing hardware components precisely and efficiently, manufacturers can avoid unnecessary expenses associated with rework or waste disposal.

Furthermore, precision hardware production for furniture batch manufacturing can help to streamline the production process by reducing lead times and improving efficiency. This can result in faster delivery times and lower prices for consumers.

Conclusion

As demand for high-quality, durable furniture continues to grow, the importance of precision hardware production for furniture batch manufacturing cannot be overstated. By selecting materials and manufacturing techniques that emphasize precision and durability, furniture manufacturers can create products that meet the needs of their customers while minimizing costs and maximizing efficiency. As such, precision hardware production should be a key focus for any serious furniture manufacturer looking to stay ahead of the competition.

Articles related to the knowledge points of this article:

Premium Baggage Hardware Customization

Title: Ranking of Metal Stamping Assembly Custom Companies in China

Title: Crafting Custom Lighting Hardware in Qingyuan: A Masterclass in Metalworking and Assembly