Title: The Processing of Electronic Cigarette Hardware Components

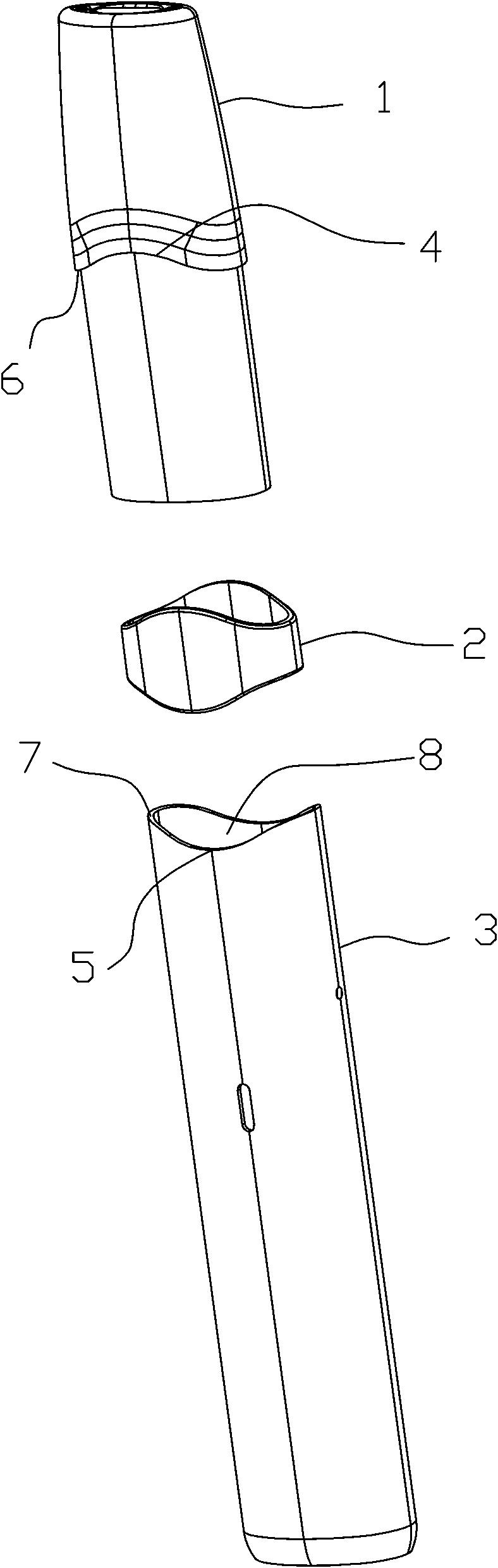

This paper presents the processing of electronic cigarette hardware components, which includes the material selection, manufacturing process, and surface treatment. The material selection process considers factors such as thermal stability, electrical conductivity, and mechanical strength. The manufacturing process involves cutting, milling, and assembly operations, while the surface treatment process includes coating, polishing, and plating techniques. The aim of these processing steps is to ensure that the electronic cigarette hardware components meet the required standards of quality and performance.

Electronic cigarettes have become increasingly popular in recent years, offering an alternative to traditional smoking. This rise in popularity has led to a surge in the demand for electronic cigarette hardware components, particularly those made from metal. As such, the processing of these hardware components has become a crucial aspect of the industry.

In this article, we will explore the processing of electronic cigarette hardware components made from metal, focusing on the key stages involved in their production. We will also discuss the importance of using high-quality metal materials and how processing techniques have evolved to meet the demands of the electronic cigarette industry.

Key Stages in the Processing of Electronic Cigarette Hardware Components

1、Metal Selection and Preparation

The first stage in the processing of electronic cigarette hardware components is selecting and preparing the metal material. High-quality metal is essential for ensuring the durability and longevity of these components. Commonly used metals include stainless steel, aluminum, and titanium. Each metal has its own unique properties that make it suitable for specific applications within the electronic cigarette hardware.

2、Cutting and Shaping

Once the metal has been selected, it is then cut and shaped to form the individual components. This stage involves using precision cutting tools and machines to ensure that each component is cut to the correct size and shape. This is a crucial step as any errors at this stage can affect the performance and reliability of the final product.

3、Surface Treatment

After cutting and shaping, the components undergo surface treatment to enhance their performance and longevity. This may involve coating the surface with a protective layer, such as a thin film of nickel or chromium, to prevent corrosion and enhance electrical conductivity. Other surface treatments may include polishing or sanding to achieve a desired finish or to remove any imperfections from the cutting process.

4、Assembly and Testing

Once all the individual components have been processed, they are then assembled together to form the final electronic cigarette hardware product. This involves connecting the various components using soldering or welding techniques. After assembly, each product is then tested to ensure its performance and reliability meet the required standards. Testing may involve checking for electrical continuity, assessing mechanical stability, and ensuring that each component functions as intended.

5、Packaging and Shipping

Once testing is complete, the electronic cigarette hardware components are then packaged for shipping to their final destination. Packaging involves using appropriate packaging materials to protect the components during transportation and ensure that they arrive in good condition. Shipping may involve using standard postal services or specialized logistics providers, depending on the distance and requirements of the customer.

Conclusion

In conclusion, processing electronic cigarette hardware components involves several key stages, including metal selection and preparation, cutting and shaping, surface treatment, assembly and testing, and packaging and shipping. Each stage is crucial in ensuring that the final product meets the desired performance standards and is durable enough to withstand regular use. By understanding these processing steps, it becomes possible to appreciate the complexity of producing high-quality electronic cigarette hardware components for use in a range of electronic cigarette devices.

Articles related to the knowledge points of this article:

Title: Hardware Fittings: The Unsung Heroes of the Construction Industry

Tea Table Hardware Components: Essential Elements for a Stylish and Functional Piece of Furniture