Title: Precision Metal Stamping and Electroplating Services in Tongxiang - Tailored Solutions for Hardware Fabrication

Tongxiang is a city that offers precision metal stamping and electroplating services for hardware fabrication. These services are tailored to meet the needs of businesses looking to produce high-quality metal components with precision and accuracy. The city's experienced technicians use advanced technology and equipment to ensure that each order is completed to the customer's specifications. From design to production, Tongxiang's metal stamping and electroplating services provide a complete solution for hardware fabrication. With a commitment to quality and attention to detail, customers can trust that their orders will be delivered on time and to specification. Whether you are a small business or a large corporation, Tongxiang's precision metal stamping and electroplating services have the expertise and resources to help you achieve your goals. Contact us today to learn more about how we can assist with your next hardware fabrication project.

Introduction

Tongxiang, a city situated in the eastern part of China, is renowned for its rich history, vibrant culture, and exceptional craftsmanship. The town's strategic location has made it a hub for various industries, particularly metalworking and fabrication. Among these industries, the hardware sector stands out as one of the most prominent due to its widespread applications in everyday life. From door handles and hinges to car parts and household appliances, hardware products play a crucial role in enhancing convenience, functionality, and aesthetics. In this context, Tongxiang's metal stamping and electroplating services have gained significant popularity among customers looking for custom-made solutions.

Metal Stamping and Electroplating Services in Tongxiang

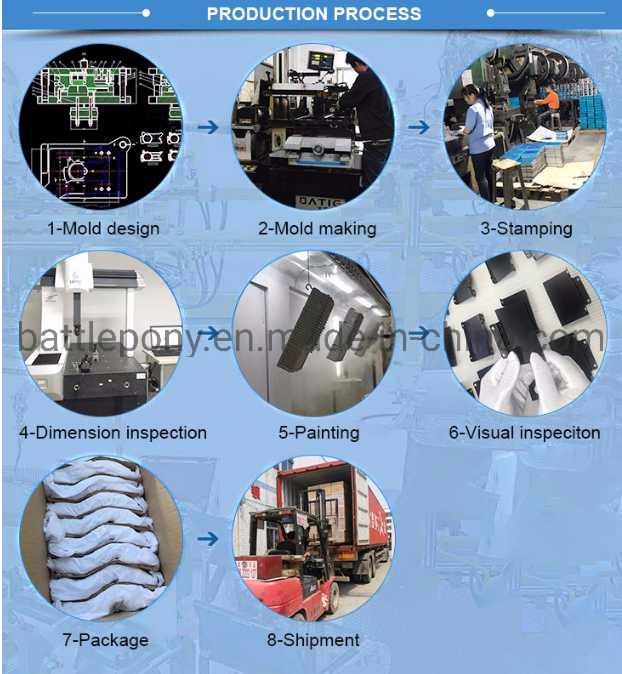

The process of metal stamping involves shaping raw materials into desired designs using precision machines that apply immense force. This technique allows for mass production of identical or slightly varied components with high accuracy and speed. The following sections provide an outline of the key features, benefits, and applications of metal stamping services in Tongxiang.

1、Design and Creation

To start the metal stamping process, clients typically provide design drawings or specifications outlining their requirements. The design team then analyzes the details to determine the appropriate material choice, size, weight, and shape. Once the design is finalized, the manufacturing unit prepares the tooling required for the stamping process by creating precise patterns on metal sheets or dies. The die is placed against the sheet to transfer the design onto the material, followed by clamping, bending, and stretching to shape the component.

2、Materials Selection

There are various metals suitable for metal stamping, depending on the application's requirements. Some of the commonly used metals include stainless steel, aluminum, iron, brass, and titanium. Stainless steel is popular due to its resistance to corrosion, heat, and impact. Aluminum is lightweight, flexible, and ideal for applications that require strength and durability without added weight. Iron and brass are durable and corrosion-resistant options suited for structural components such as gears and shafts. Titanium is a versatile metal with excellent strength-to-weight ratio, making it suitable for aerospace and automotive applications where weight reduction is critical.

3、Quality Control

Quality control plays a crucial role in ensuring that metal stamping components meet customer specifications and expectations. Tongxiang's manufacturing units employ rigorous quality assurance measures, including visual inspections, dimensional checks, and surface finishes assessment. Additionally, they use state-of-the-art testing equipment such as X-ray machines, CT scanners, and micrometers to verify the accuracy and consistency of the components. These measures ensure that only high-quality products leave the facility and meet international standards.

4、Assembly and Packaging

Once the metal stamping process is complete, the components are ready for further processing or assembly. Depending on the final product's complexity, additional steps may include drilling, welding, painting, or polishing. Tongxiang's experienced technicians can handle any customization requirement or assemble components according to specific instructions provided by customers. Once assembled, the components are packaged carefully to prevent damage during transit and storage.

5、Electroplating Services

Electroplating is a surface finishing technique that involves applying a thin layer of metal onto a substrate using an electric current. The process can improve the aesthetic appeal of components while providing additional protection against wear and corrosion. Tongxiang offers a range of electroplating services catering to various needs, including:

a) Zinc Plating: A cost-effective option for coating low-cost metals such as iron and brass with a durable zinc layer. Zinc plating helps prevent rust formation while improving surface hardness and corrosion resistance. It is commonly used in household items like kitchenware and furniture.

b) Chrome Plating: An advanced plating technique that produces a lustrous silver-gray finish on steel or other metals. Chrome plating provides superior durability and resistance to corrosion compared to other plating methods. It is commonly used in automotive parts, industrial equipment, and decorative items like jewelry and watches.

c) Dacromet Plating: A premium plating technique that creates a thick layer of nickel-chromium alloy over steel surfaces. Dacromet plating provides excellent corrosion resistance and surface hardness but comes at a higher cost compared to other plating methods. It is commonly used in high-end automotive parts, medical devices, and electronic equipment.

Conclusion

Tongxiang's metal stamping and electroplating services offer a comprehensive solution for customers seekingcustomized hardware solutions that meet their specific requirements. By utilizing advanced technologies and skilled professionals

Articles related to the knowledge points of this article:

Custom Cabinet Folding Door Hardware

Custom Furniture Hardware Brands: A Comprehensive Guide

Title: Guangdong Customized Hardware Exhibition

ZHOUSHAN Ouwei Customized Hardware: Quality and Precision Meet in this Fishing City

Title: Exploring the Professionalism and Quality of Huzhou Metal Storage Racks Manufacturer