Title: Customized Metal Hardware and Aluminum Components in Kunming: A Comprehensive Guide

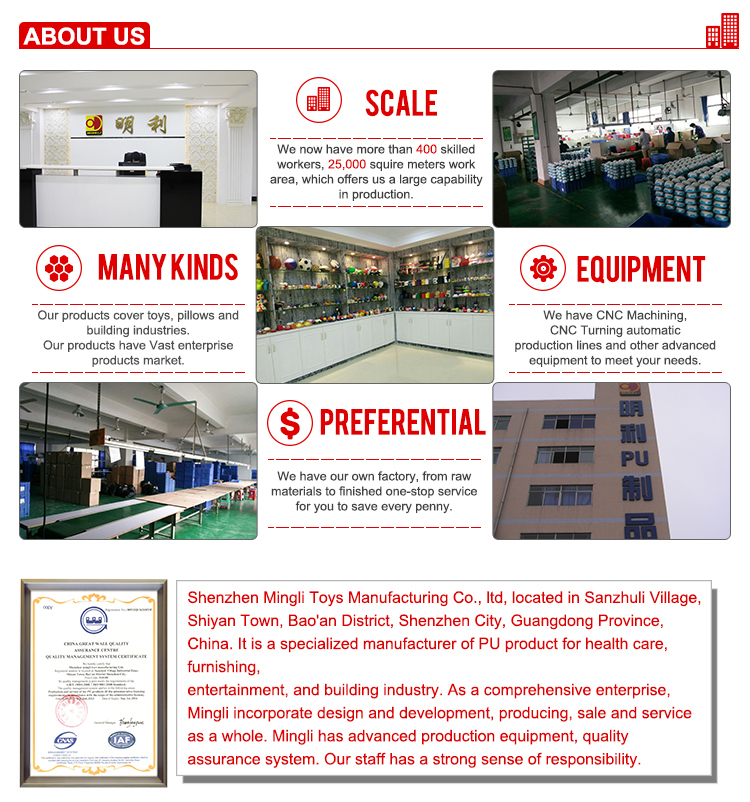

Kunming, a city in southwest China, is renowned for its specialized metal hardware and aluminum components industry. With a long history of manufacturing and advanced production technology, Kunming's hardware and component industry has been widely recognized and praised by customers both domestically and internationally. ,The customization service offered by the industry ensures that customers can tailor their products to their specific needs, making it a popular choice for companies looking to create unique or one-of-a-kind products. The use of high-quality materials such as aluminum not only enhances the durability and strength of the products but also reduces their weight, making them ideal for applications in various fields including aerospace, automotive, and construction. In addition, the industry has actively embraced sustainable development practices, ensuring that the production process is environmentally friendly. As a result, Kunming's metal hardware and aluminum component industry has become an essential part of the city's economy, contributing significantly to its growth and development.

Introduction:

Kunming, a city in southern China known for its mild climate and vibrant culture, has long been a hub for manufacturing industries. Among these industries, the metal hardware and aluminum component sector has seen a significant growth rate in recent years. With the increasing demand for customized products, many companies in Kunming have started offering tailored solutions to meet the specific needs of their clients. This article aims to provide a comprehensive guide on customized metal hardware and aluminum components in Kunming, covering various aspects such as materials, production processes, design options, and delivery.

Materials:

When it comes to custom metal hardware and aluminum components, the choice of material is crucial. Kunming offers a wide range of materials to choose from, including steel, brass, copper, aluminum, and plastic. Each material has its own set of properties that determine its suitability for different applications. For example, steel is commonly used for structural components due to its strength and durability; brass is favored for its attractive appearance and resistance to corrosion; copper is popular for its electrical conductivity and aesthetic appeal; aluminum is lightweight and versatile, making it ideal for aerospace and automotive applications; and plastics offer low maintenance and cost-effective alternatives for non-structural parts.

Production Processes:

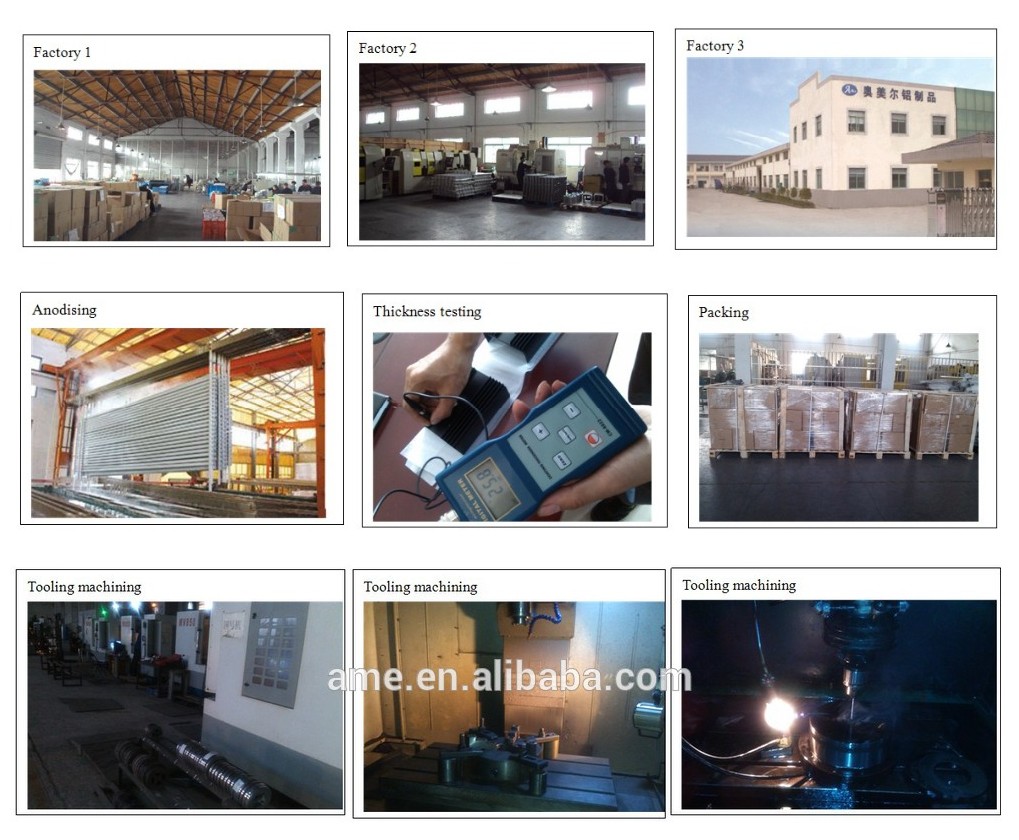

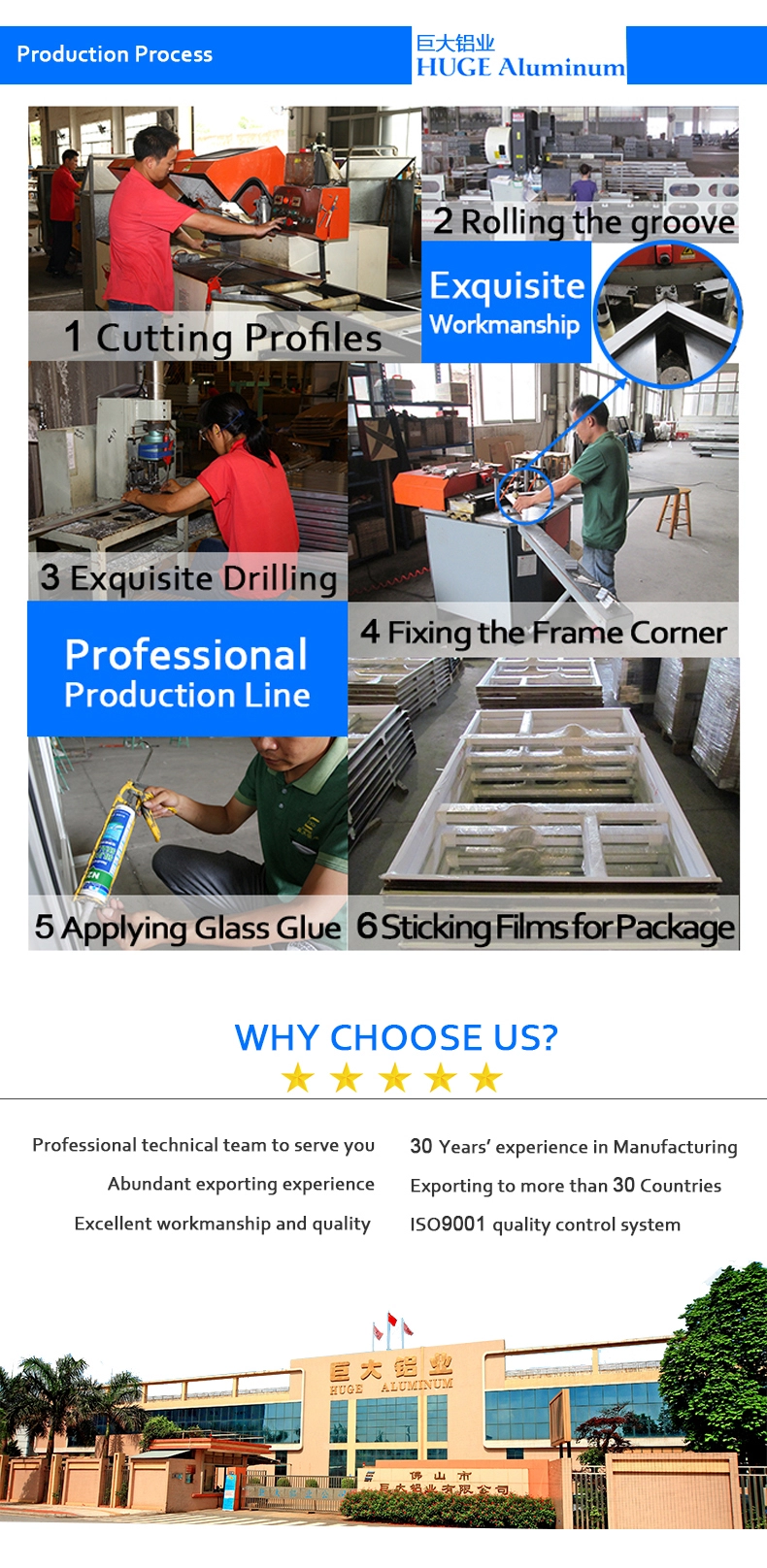

The production process of customized metal hardware and aluminum components in Kunming typically involves several stages, starting from the design phase to final assembly and quality inspection. The first step is to understand the specific requirements of the client and develop a detailed design plan. This may involve creating prototypes or mockups to test the functionality and aesthetics of the product. Once the design is finalized, the next step is to manufacture the raw materials into finished components using specialized equipment and machinery. Some common production techniques include cutting, bending, welding, stamping, drilling, and grinding. After the components are produced, they are subjected to rigorous quality control measures to ensure compliance with industry standards and customer expectations. Finally, the components are packaged and shipped to the destination according to the client's specifications.

Design Options:

One of the key advantages of custom metal hardware and aluminum components in Kunming is the availability of diverse design options. Customers can choose from a wide variety of shapes, sizes, colors, textures, and finishes to create a unique product that reflects their brand identity and style preferences. Some popular design features include engraved or embossed patterns, brushed or polished finishes, laser engravings, and custom branding elements. Additionally, some manufacturers offer customization services such as adding additional features like LED lighting or Bluetooth connectivity to enhance the functional capabilities of the product.

Conclusion:

In conclusion, Kunming has emerged as a leading destination for customized metal hardware and aluminum components due to its strong manufacturing base and skilled workforce. With a vast array of materials, production processes, design options, and delivery services available, customers can benefit from tailor-made solutions that meet their specific requirements and exceed their expectations. As the industry continues to grow and evolve, Kunming's role as a hub for innovation and creativity is expected to expand further, providing new opportunities for businesses looking to differentiate themselves in today's competitive market.

Articles related to the knowledge points of this article:

Title: Crafting Custom Hardware: The Art of Shanghais Metal Door Handle Manufacturing