Title: An In-Depth Analysis of the Henan Small Hardware Components Inspection Checklist

The Henan Small Hardware Components Inspection Checklist is a comprehensive document that provides detailed instructions for inspecting small hardware components in Henan province. The checklist covers various aspects of inspection, including visual inspection, dimensional inspection, and functional inspection. It also includes specific requirements for each component type, such as screws, bolts, and nuts. One of the key features of the Henan Small Hardware Components Inspection Checklist is its emphasis on quality control. The checklist requires that all inspected components meet certain standards, such as accuracy, uniformity, and consistency. This helps to ensure that products manufactured in Henan are of high quality and meet customer expectations. Another important aspect of the Henan Small Hardware Components Inspection Checklist is its use of advanced technology. The checklist incorporates modern inspection tools and equipment, such as automated visual inspection systems and precision measuring devices. This not only improves the efficiency of the inspection process but also enhances the accuracy of results. Overall, the Henan Small Hardware Components Inspection Checklist plays a crucial role in ensuring the quality and consistency of small hardware components in Henan province. By following this checklist, manufacturers can ensure that their products meet strict quality standards and deliver value to customers.

In today's fast-paced business environment, efficiency and accuracy are paramount. This is particularly true in the manufacturing industry, where small hardware components play a crucial role. These components, such as screws, bolts, and nuts, may seem trivial, but they are the building blocks of almost any structure or machine. Their quality can make or break a product's functionality, longevity, and overall safety. Therefore, it is essential to have a robust system in place for inspecting these components to ensure they meet specified standards.

This is where the Henan Small Hardware Components Inspection Checklist comes into play. This checklist serves as a comprehensive guide for verifying that each small hardware component meets the necessary quality standards. It covers all aspects of inspection, from visual inspection to chemical analysis. Let's delve deeper into what this checklist contains and how it helps maintain product quality.

The inspection process begins with a visual inspection. This involves examining each component to check for any signs of damage, wear, or defects. The inspector must pay close attention to the surface finish, dimensions, and tolerances specified for each component. Any discrepancies should be documented and reported to the appropriate team for further investigation.

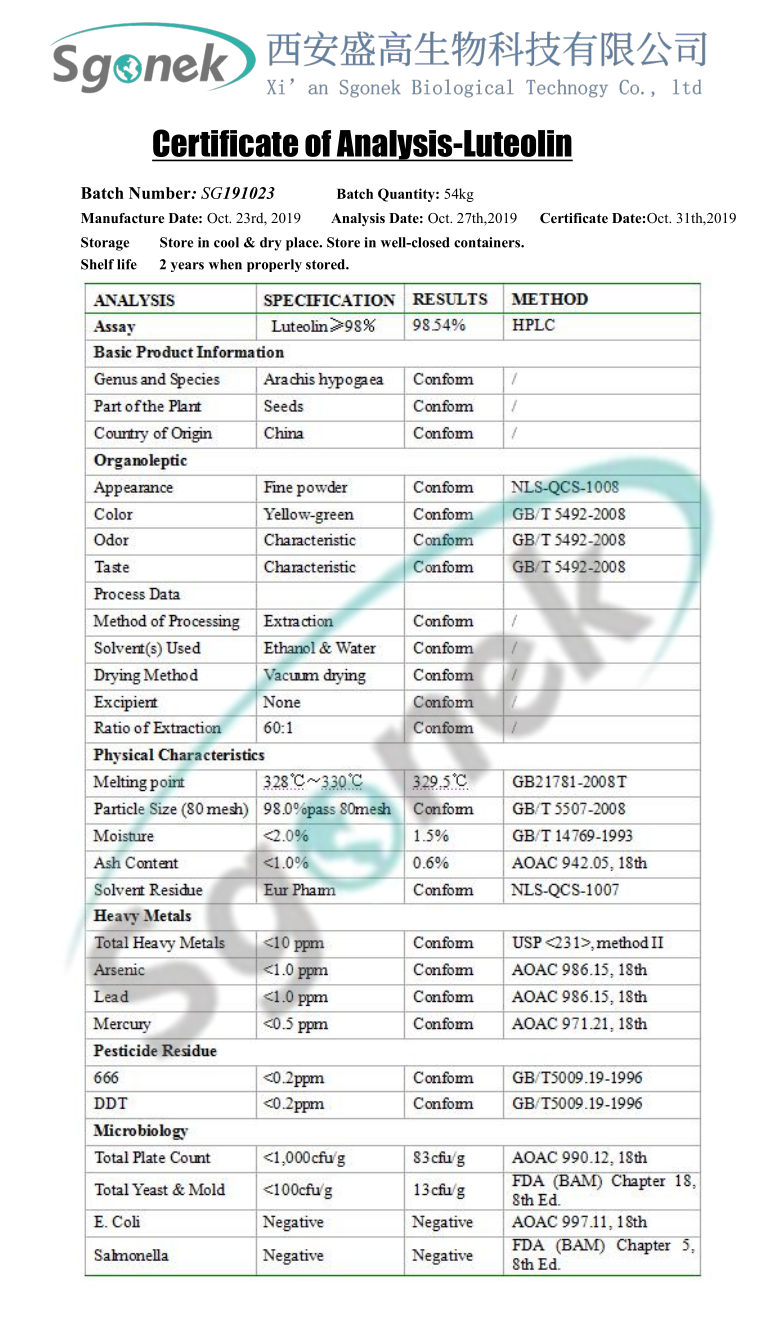

Next up is the chemical analysis stage. Here, various tests are performed to determine the composition and properties of each component. These tests may include hardness testing,磁性测试,电导率测试等。 The results of these tests help ensure that each component meets the required specifications and is free from any harmful substances.

Another critical aspect of the inspection process is the testing of each component's strength and durability. This may involve subjecting the component to different loading conditions to gauge its resistance to stress and strain. The inspector must document any issues that arise during these tests and report them to the relevant team for resolution.

In addition to these more traditional methods of inspection, technology has also been integrated into the checklist to increase efficiency and accuracy. For instance, some factories now use automated scanning systems to quickly identify any defects on components as they pass through an inspection area. This not only saves time but also reduces the likelihood of human error.

The Henan Small Hardware Components Inspection Checklist is designed to be flexible and adaptable to different manufacturing processes and products. It can be easily customized based on the specific requirements of each factory or product line. This ensures that each component receives a thorough and accurate inspection, regardless of its intended use.

However, it's important to note that while the Henan Small Hardware Components Inspection Checklist plays a crucial role in maintaining product quality, it is not a standalone solution. Factory managers and employees must also take an active role in ensuring that each component is inspected correctly and consistently throughout the production process. This includes proper training for new employees, regular review and updates of the checklist, and effective communication between departments.

In conclusion, the Henan Small Hardware Components Inspection Checklist is a powerful tool for ensuring that each small hardware component meets specified quality standards. By combining traditional inspection methods with innovative technologies, it enables factories to operate efficiently while maintaining high levels of product quality. However, its effectiveness depends on the commitment and cooperation of all parties involved in the manufacturing process. With the right mindset and approach, any factory can benefit from implementing such a comprehensive inspection system.

Articles related to the knowledge points of this article:

Assembly of Bed Hardware Accessories

Title: Top 10 Largest Hardware Accessories Brands in Shanxi Province

Title: Reliable Hardware Accessories in Dongguan: Your One-Stop Solution for All Your Needs

Title: Exploring the Reputable Hardware Equipment and Machinery Industry in Zhaoqing

Garden Hardware Fittings: A Comprehensive Guide

Title: Exploring the Quality of Hardware Accessories in Jiangxi at Direct Factory Prices