Nanjing Hardware Manufacturers: A Look into Their Production Process

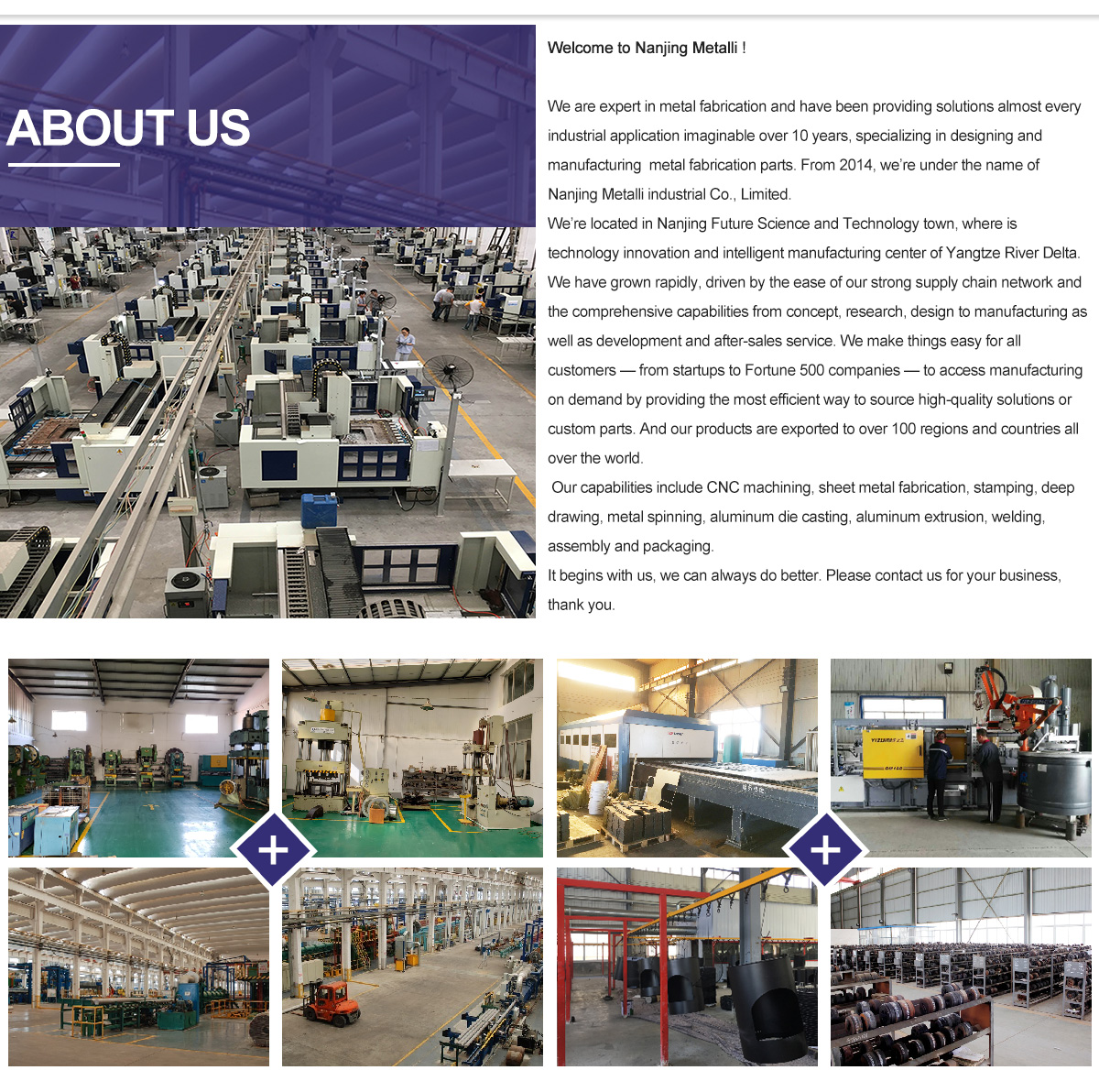

Nanjing hardware manufacturers have been providing high-quality products to customers worldwide for many years. Their production process is based on the use of advanced machinery and technology, which ensures that each product produced meets the highest standards of quality and performance. The manufacturers also have a team of skilled and experienced professionals who oversee the entire production process to ensure that all products are produced with precision and accuracy. From raw material selection to final product inspection, each step is carefully controlled to ensure that the products meet the specifications and requirements of their customers. This attention to detail and commitment to quality has made Nanjing hardware manufacturers a trusted name in the industry.

Nanjing, the capital of Jiangsu Province, is home to numerous hardware manufacturers. These manufacturers have a long history of producing high-quality hardware products, serving various industries and markets worldwide. In this article, we will explore the production process of Nanjing hardware manufacturers, looking at the different stages and steps involved in creating these products.

The first stage of production at Nanjing hardware manufacturers is raw material selection. Manufacturers choose high-quality raw materials to ensure that their products have the necessary durability and longevity. These materials may include steel, aluminum, copper, plastic, or other materials, depending on the type of hardware being produced.

Once the raw materials are selected, they undergo cutting and shaping to create the desired product shapes. This step is crucial in ensuring that the products have the correct dimensions and shapes to meet customer specifications. Cutting and shaping processes may involve using machines such as CNC machines, lasers, or waterjets, depending on the manufacturer's capabilities and needs.

After cutting and shaping, the products undergo surface treatment to enhance their appearance and protect them from corrosion or damage. Surface treatments may include painting, coating, polishing, or other processes, depending on the specific product requirements. This step is crucial in ensuring that the products have a smooth, aesthetically pleasing surface that is also functional and durable.

Once the surface treatment is completed, the products are inspected to ensure that they meet the required quality standards. This inspection process involves checking the dimensions, shape, surface finish, and other aspects of the products to ensure that they are all within acceptable limits. Any products that do not meet these standards are rejected and returned to the previous stages for further processing.

Finally, the products are packaged and shipped to the customer. Packaging may involve wrapping the products in plastic or cardboard boxes, labeling them with necessary information such as product name, manufacturer name, and contact details. The products are then loaded onto trucks or containers for transportation to the customer's specified location.

In conclusion, Nanjing hardware manufacturers have a well-established production process that involves raw material selection, cutting and shaping, surface treatment, inspection, packaging, and shipping. This process ensures that customers receive high-quality hardware products that meet their specifications and requirements. By understanding this process, customers can have a better understanding of how their products are made and ensure that they are receiving the best possible quality from these manufacturers.

Articles related to the knowledge points of this article:

Henan Hardware Manufacturers: A Comprehensive Guide

Henan Window Hardware Manufacturers

Title: Exploring the World of Hangzhou Kitchen Cabinet Hardware Manufacturers