CUSTOMIZATION OF HARDWARE MOULDS

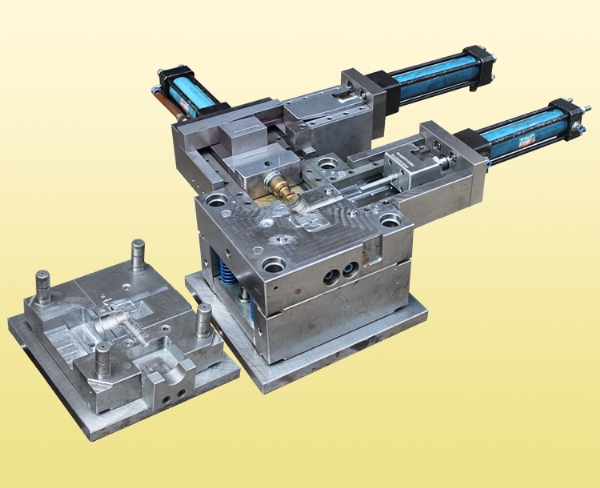

This paper discusses the customization of hardware moulds, which is a crucial process in the manufacture of hardware products. The term 'hardware mould' refers to a tool that is used to shape raw materials into the desired product form. Customization involves modifying the design and shape of the mould to meet the specific requirements of a hardware product. By understanding the principles and processes involved in hardware mould customization, manufacturers can produce products that are tailored to meet the needs of their customers. This approach can significantly enhance product quality, performance, and market competitiveness.

In today’s manufacturing industry, hardware moulds play a crucial role in the production process. These moulds are essential for shaping and cutting materials into desired forms. As such, they must be designed and manufactured to meet specific requirements and standards to ensure the production of high-quality products. One of the benefits of using custom-made hardware moulds is that they can be tailored to meet the unique needs of each individual business.

In this article, we will explore the importance of hardware mould customization in manufacturing and discuss the process involved in creating these tailor-made moulds. We will also highlight the benefits of using customized hardware moulds and address some of the challenges associated with them. By the end of this article, you should have a clear understanding of how hardware mould customization contributes to the overall productivity and efficiency of manufacturing operations.

THE IMPORTANCE OF HARDWARE MOULD CUSTOMIZATION IN MANUFACTURING

In manufacturing, hardware moulds are used in various processes, including plastic moulding, metal stamping, and rubber moulding. These moulds are designed to shape and cut materials into specific forms to create finished products. However, off-the-shelf moulds may not meet the unique needs of each business, which is why hardware mould customization is essential.

Customized hardware moulds can be tailored to meet specific production requirements, such as material type, shape, size, and tolerance levels. This ensures that each business can use the right tool for the job, resulting in increased productivity and efficiency. Additionally, customized hardware moulds can help businesses reduce their reliance on expensive third-party manufacturers by providing them with a cost-effective solution to meet their production needs.

PROCESS OF CREATING CUSTOMIZED HARDWARE MOULDS

Creating customized hardware moulds involves several steps. Firstly, businesses need to identify their specific production requirements, such as material type, shape, size, and tolerance levels. Once these requirements are determined, businesses can begin designing the mould using CAD software. This software allows businesses to create 3D models of the mould to ensure accuracy and fit before manufacturing.

Once the design is completed, businesses can proceed to manufacture the mould using CNC machining or other suitable techniques. This step ensures that the mould is precisely manufactured to meet the specified requirements. Following manufacturing, businesses can test the mould to ensure its performance and reliability before putting it into production.

BENEFITS OF USING CUSTOMIZED HARDWARE MOULDS

There are several benefits of using customized hardware moulds in manufacturing. Firstly, they can help businesses meet their specific production requirements, resulting in increased productivity and efficiency. Secondly, customized hardware moulds can help businesses reduce their reliance on expensive third-party manufacturers by providing them with a cost-effective solution to meet their production needs. Thirdly, customized hardware moulds can also help businesses improve product quality by ensuring that each product is produced to the same high standards.

CHALLENGES ASSOCIATED WITH CUSTOMIZED HARDWARE MOULDS

While customized hardware moulds offer numerous benefits, there are also some challenges associated with them. One major challenge is the upfront cost of creating customized moulds. This cost can be significant, depending on the complexity of the mould design and material type used. Additionally, there is also a risk that the customized mould may not meet expectations if it is not designed or manufactured correctly. This can result in wasted time and resources on re-designing or re-manufacturing the mould to meet the desired specifications.

In conclusion, hardware mould customization plays a crucial role in manufacturing, offering numerous benefits such as increased productivity, efficiency, and product quality while also addressing challenges such as upfront costs and risks associated with incorrect design or manufacture. By understanding these benefits and challenges associated with customized hardware moulds, businesses can make informed decisions about whether or not to use them in their manufacturing operations based on their unique needs and circumstances.

Articles related to the knowledge points of this article:

Title: Customizing Hardware Components in Xiaolan: The Art of Craftmanship and Innovation

Title: Exploring the Best Hardware for Customized Cabinet Doors: A Comprehensive Guide