无人机五金厂家,生产技术与市场趋势分析

Abstract:This article focuses on the无人机五金厂家的生产技术与市场趋势. It discusses the production techniques employed by these manufacturers, emphasizing on their advancements in drone hardware components manufacturing. Furthermore, it examines the current market trends, including the growth of unmanned aerial vehicles (UAVs) and the evolving demand for high-quality drone components. The article also delves into the market potential and future prospects of these manufacturers, considering technological advancements and market competition. Overall, it provides a comprehensive overview of the industry's state and its future outlook.

In the rapidly growing field of unmanned aerial vehicles (UAVs), hardware components play a pivotal role. As one of the leading manufacturers in the drone industry, drone hardware manufacturers, especially those specializing in五金 (metal components), are at the forefront of this technological revolution. This article delves into the production techniques and market trends of drone metal manufacturers.

一、无人机五金厂家的生产现状分析

Drones, being complex machinery, require a wide range of metal components for their construction. This includes critical parts such as frames, rotors, batteries, and other structural elements. As a result, drone metal manufacturers have emerged as a significant segment in the UAV supply chain. These manufacturers utilize advanced production techniques to ensure the quality and durability of their products.

Modern drone metal manufacturers utilize a combination of traditional manufacturing processes like casting, forging, and machining, with cutting-edge technologies like 3D printing and additive manufacturing. These techniques enable them to produce lightweight yet strong components that are essential for the performance of drones. Additionally, they also focus on material selection, often opting for lightweight metals like titanium and aluminum alloys that offer high strength-to-weight ratio.

二、生产技术探讨

The production technology employed by drone metal manufacturers is constantly evolving. 3D printing, in particular, has gained significant attention due to its ability to produce complex shapes and designs that are difficult to achieve through traditional manufacturing methods. This technology allows for the customization of components and reduces the overall manufacturing time and cost.

Moreover, drone metal manufacturers are also investing in research and development to improve the efficiency and reliability of their production processes. They are exploring new materials like composite metals and high-performance alloys that can offer better performance and longer lifespan for drones. Additionally, they are adopting advanced quality control measures to ensure that each component meets the stringent quality standards required for aerospace applications.

三、市场趋势分析

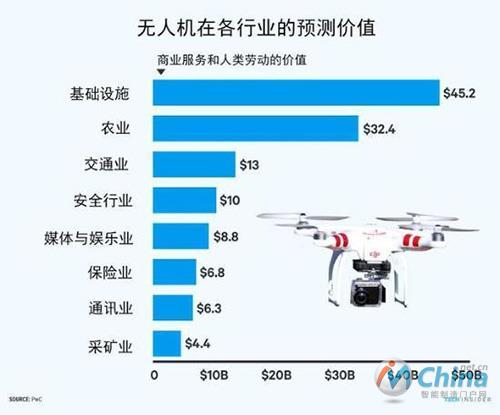

The market for drones is rapidly expanding, driven by various factors such as advancing technology, decreasing costs, and the emergence of new applications. This growth is leading to increased demand for high-quality metal components from drone metal manufacturers.

One of the key trends in the drone industry is the increasing adoption of electric propulsion systems, which are more efficient and environmentally friendly compared to traditional fuel-powered drones. This shift is leading to a surge in demand for lightweight metal components that can withstand the demands of electric propulsion systems. Additionally, the rise of autonomous drones is also driving the demand for advanced metal components that can support complex flight control systems.

Another trend that is influencing the drone metal manufacturing industry is the growing demand for customized drones in various industries such as agriculture, construction, and law enforcement. This trend is leading to a rise in the demand for customized metal components that can cater to specific needs and requirements of different industries.

四、结论

Drone hardware manufacturers specializing in metal components are at the forefront of the drone industry's technological revolution. They are adopting advanced production techniques and exploring new materials to produce high-quality metal components that can cater to the growing demand in various industries. With the market for drones expanding rapidly, these manufacturers are poised to play a pivotal role in shaping the future of this industry.

As the drone industry continues to evolve, it will be interesting to see how drone metal manufacturers adapt to these changes and continue to innovate in order to stay competitive in this rapidly growing market.

Articles related to the knowledge points of this article:

Title: Finding the Right Metal Supplier: A Comprehensive Guide to Crafting the Perfect Pitch

Title: Korean Kitchen Hardware Manufacturers: A Review of the Industry