Telescope压铸五金配件,工艺、应用与发展趋势

Abstract:This article focuses on the Telescope压铸五金配件, discussing its craftsmanship, applications, and developmental trends. The article begins with an introduction to the basic concept and manufacturing process of Telescope压铸五金配件. It then delves into the various applications of this product in different industries, highlighting its significance in enhancing performance and usability. Furthermore, the article explores the current and future trends in the development of Telescope压铸五金配件, emphasizing on the innovation and technological advancements that are driving its evolution. The conclusion summarizes the overall importance of this product in various fields and its potential for further growth and improvement.

In the field of astronomy and optics, telescope压铸五金配件 play a pivotal role in enhancing the performance and precision of telescopes. These metal components are not just structural supports but are also integral parts of the entire optical system, ensuring accurate alignment and durability. As the demand for high-performance telescopes increases, the need for advanced and sophisticated telescope压铸五金配件 has also grown significantly.

Process of Telescope Die-Casting Metal Parts

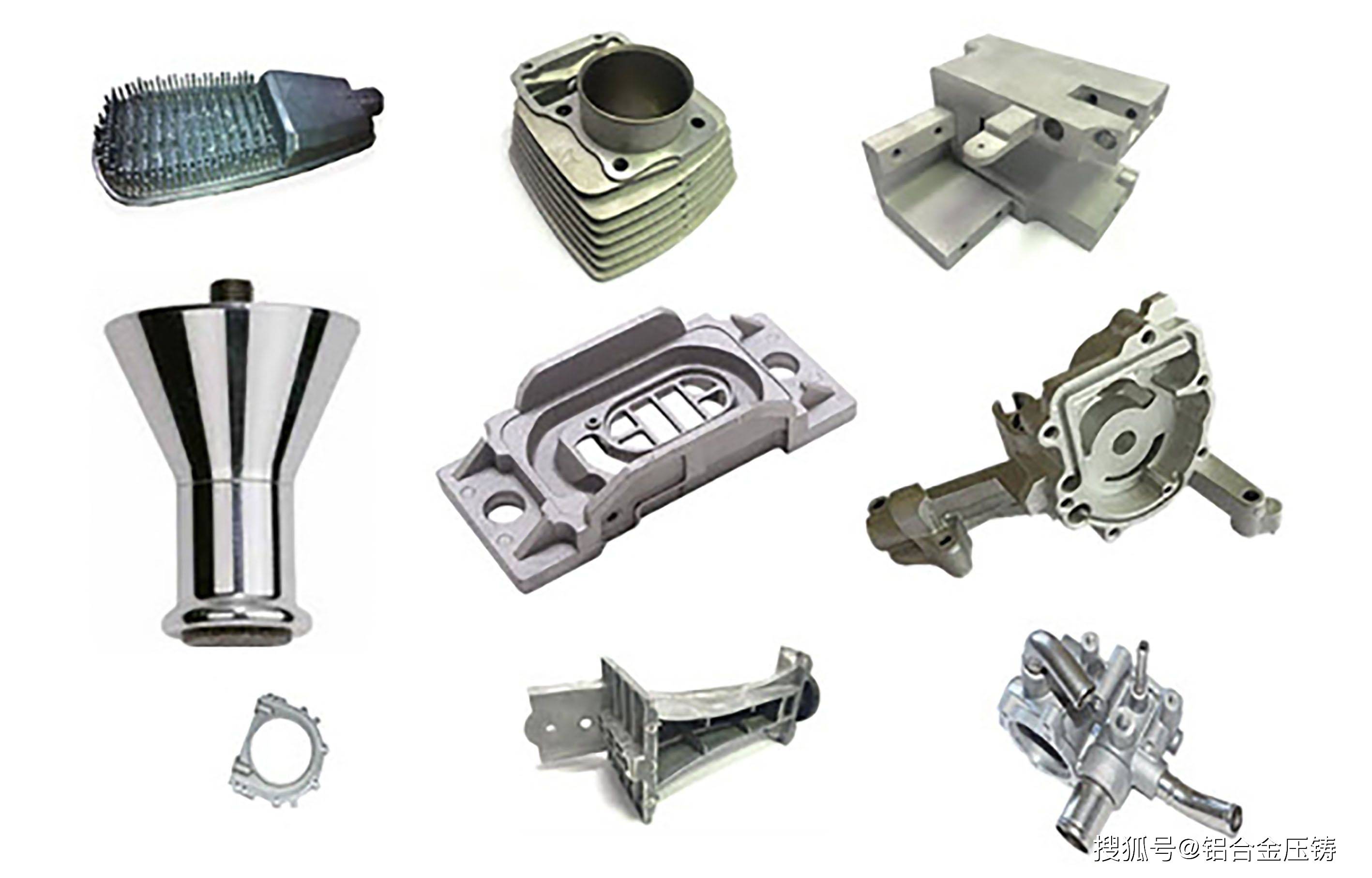

The process of manufacturing telescope压铸五金配件 involves several stages, starting from the design phase to the final quality check. The die-casting process is a crucial step in this manufacturing chain. Here’s a brief overview of the process:

1、Design and Material Selection: The initial stage involves designing the metal parts using CAD software, considering the mechanical and optical properties required for the specific application. The material selection is crucial as it needs to be lightweight, strong, and resistant to corrosion. Zinc, aluminum, and magnesium alloys are commonly used for telescope components.

2、Die Preparation: After the design is finalized, the die is prepared using high-grade steel. The design is carved into the die using CNC machining techniques.

3、Molten Metal: The chosen metal is melted in a furnace and kept at an elevated temperature to maintain its fluidity.

4、Die Casting: The molten metal is injected under high pressure into the die, which shapes the metal according to the design.

5、Post-Processing: After the initial casting, the parts undergo several post-processing steps like deburring, polishing, and machining to achieve the final shape and dimensions.

6、Quality Check: Each component undergoes rigorous quality checks to ensure they meet the specified standards in terms of mechanical strength, optical quality, and durability.

Applications of Telescope Die-Casting Metal Parts

The telescope压铸五金配件 are used in various applications within the telescope system. Some of the key applications include:

1、Truss Tubes and Mountings: These metal parts provide structural support to the telescope and ensure stability during observations.

2、Lens Barrels and Cell Holders: These components hold the lenses and other optical elements in place, ensuring accurate alignment and focusing.

3、Adjustable Rings and Rings Supports: These metal rings are used to adjust and focus the telescope, providing precise positioning for precise observations.

4、Tripods and Platforms: The base of the telescope requires sturdy metal parts to support its weight and provide stability during operation.

Trends in Telescope Die-Casting Metal Parts Manufacturing

With the evolution of technology and growing demand for high-performance telescopes, there are several emerging trends in the manufacturing of telescope压铸五金配件:

1、Material Innovation: Manufacturers are exploring new materials like high-strength alloys and composite materials that offer better mechanical and optical properties.

2、Automation and Robotics: The use of robots and automated machines is increasing in the manufacturing process, reducing human intervention and enhancing productivity.

3、3D Printing: 3D printing technology is being explored for manufacturing customized and complex-shaped metal parts.

4、Sustainable Manufacturing: Manufacturers are focusing on sustainable manufacturing practices to reduce waste, energy consumption, and environmental impact.

Conclusion

Telescope压铸五金配件 are crucial components in enhancing the performance and precision of telescopes. The manufacturing process involves multiple stages, starting from design to final quality check. With the evolution of technology, there are several emerging trends in this field, which offer exciting opportunities for innovation and improvement.

The future of telescope manufacturing lies in developing advanced materials, adopting sustainable manufacturing practices, and integrating modern technologies like automation and 3D printing to enhance productivity and reduce costs. As we look forward to exploring the vast universe, these advancements in telescope压铸五金配件 will play a pivotal role in unlocking its mysteries.

Articles related to the knowledge points of this article:

Aluminum Alloy Door and Window Hardware Fittings

Title: Established and Well-Supplied Sanwei Hardware Parts in Shanwei, Guangdong Province

Vita Hardware Components: The Key to Quality and Performance

Title: Where to Find Cheap and High-Quality Hardware Accessories for Your Project?