Title: Customizing Metallic Components in Bengbu: The Ultimate Guide to Rubber Bending

Title: Customizing Metallic Components in Bengbu: The Ultimate Guide to Rubber BendingBengbu, a city in China's Anhui province, has long been known for its expertise in producing metal components. One of the key skills involved in creating these components is rubber bending, a process used to shape metal into various forms. In this ultimate guide, we delve into the world of custom metallic components and explore the art of rubber bending.The first step in creating custom metal components is understanding the requirements of the customer. This involves discussing design preferences, material choice, and production specifications. With this information, the team at Bengbu begins crafting the components using state-of-the-art machinery and tools.Once the initial design has been created, it's time to apply the rubber bender technique. This delicate process involves heating up the metal piece and applying pressure to create a specific shape. Skilled craftsmen use their years of experience and expertise to ensure that each component is shaped to perfection.As you progress through the rubber bending process, it's essential to maintain consistency in quality control. This involves regularly inspecting the components to identify any defects or imperfections. If necessary, the metal pieces are reshaped until they meet the desired standards.Custom metallic components produced in Bengbu are highly valued for their superior quality and durability. These components can be utilized in various applications, from automotive manufacturing to industrial equipment. So if you're looking to create custom metal components with unparalleled craftsmanship, look no further than Bengbu and its expert rubber benders.

Bengbu, a city situated in the eastern part of China, is renowned for its metalworking industry. One of the key products that Bengbu excels in is the manufacturing of metallic components, particularly rubber bending. These components are widely used in various industries, including automotive, construction, and aerospace. In this article, we will delve into the world of customizing metal components in Bengbu, exploring the process, benefits, and tips for success.

Metallic Component Manufacturing: A Comprehensive Overview

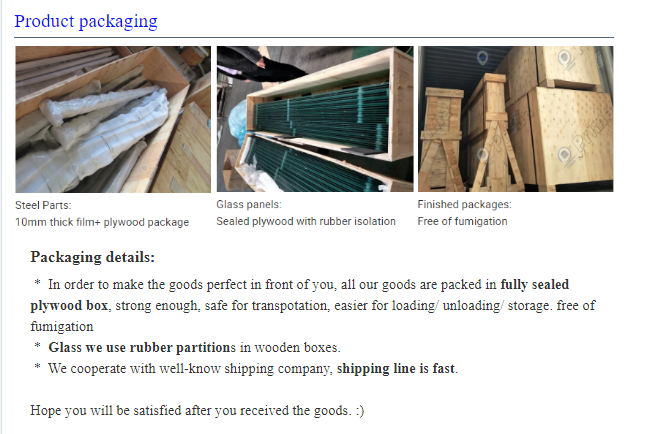

At its core, the production of metal components involves several crucial steps. The process begins with designing the component using computer-aided design (CAD) software. Once designed, the component is then cut from a solid block of metal using specialized cutting tools. The component is then shaped and polished to achieve the desired specifications. Finally, the component is tested for strength and durability before being packaged and shipped.

The Benefits of Custom Metal Components in Bengbu

There are numerous benefits to choosing Bengbu for your custom metal component needs. Firstly, Bengbu boasts a highly skilled workforce with decades of experience in metalworking. This ensures that your components are manufactured to the highest standards possible. Secondly, Bengbu offers a wide range of metal types and alloys to choose from, allowing you to select the perfect material for your project. Thirdly, Bengbu's efficient production processes ensure that your components are delivered quickly, reducing lead times and maximizing your productivity. Lastly, Bengbu's commitment to quality assurance means that your components are guaranteed to be durable and reliable.

Tips for Successful Custom Metal Component Manufacturing in Bengbu

Now that you understand the benefits of custom metal components in Bengbu, let's explore some tips for ensuring successful production. Firstly, it is essential to work closely with your manufacturer to define your specific requirements accurately. This includes specifying materials, dimensions, and other critical details. Secondly, be prepared to provide detailed engineering drawings or CAD files to ensure that the final product meets your expectations. Thirdly, consider conducting pre-production tests to verify that your components meet safety and performance standards. Finally, maintain open lines of communication with your manufacturer throughout the production process to address any issues that may arise.

Case Study: Custom Rubber Bending Components in Bengbu

A leading automotive company located in China sought to customize rubber bending components for their new assembly line. They turned to a reputable manufacturer in Bengbu for assistance. After working closely with the manufacturer, they were able to specify their requirements accurately and receive high-quality components within their required timeline. The custom components not only met their safety and performance standards but exceeded their expectations. As a result, the automotive company was able to increase their production efficiency and profitability.

Conclusion

In summary, Bengbu offers an unparalleled level of expertise and craftsmanship when it comes to custom metal components, particularly rubber bending. By following the tips outlined in this article and working closely with a reputable manufacturer like those based in Bengbu, you can ensure that your custom components are manufactured to the highest standards possible, delivering exceptional value and performance for your business. So why wait? Start planning your next custom metal component project today!

Articles related to the knowledge points of this article:

Custom Function Hardware for an Entire House: Pictures and More

Title: The Art and Science of Customization in CNC Hardware Processing in Henan Province

Title: Custom Hardware for Windows and Doors in Ningbo

Engineering Hardware Customization: Advantages and Challenges

Title: Customized Local Hardware Solutions in Suzhou: A Comprehensive Guide