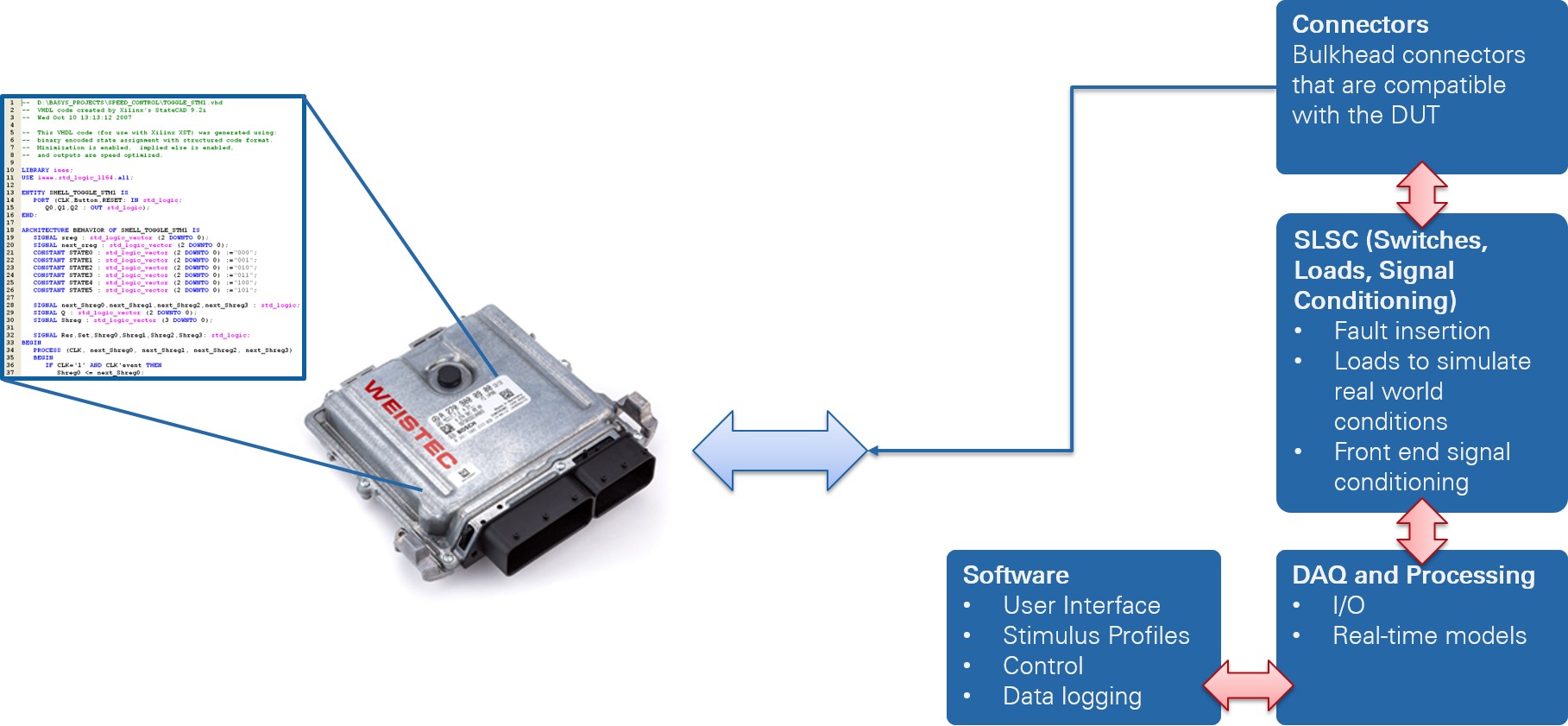

What is Customized Hardware?

Customized Hardware refers to hardware components that are specifically designed and built to meet the unique requirements of an individual or a business. This may include customized computers, servers, routers, or any other device that requires specific hardware configurations to perform specific tasks efficiently. Customized hardware offers flexibility and scalability, allowing users to tailor their hardware to their specific needs, rather than being limited to standard off-the-shelf options. It is often used in high-performance computing, data centers, and other specialized applications where standard hardware cannot meet the demands of the task. The customization process involves selecting the right components, designing the system architecture, and integrating the hardware to ensure optimal performance and reliability.

In today's world of personalized products and services, customized hardware has become an integral part of various industries, including construction, manufacturing, and even the automotive industry. Customized hardware refers to a process where specific metal components are designed and produced according to individual needs and specifications. These components are tailored to meet specific requirements and are often used in a range of applications.

In simple terms, “五金定制” in English translates to “customized hardware.” This process involves several steps that ensure the final product meets the desired quality, performance, and aesthetic standards. Here is an overview of what customized hardware entails.

Design and Specification

The first step in customized hardware involves the design and specification process. This involves working closely with the client to understand their requirements and preferences. The client may provide a specific design or concept, or the manufacturer may suggest designs based on their expertise and experience. The design process considers factors such as material, shape, size, finish, and performance requirements.

Once the design is finalized, the specifications are developed. These specifications detail the exact requirements of the component, including its dimensions, material properties, and manufacturing processes. This information is crucial for the manufacturer to produce the component accurately and efficiently.

Manufacturing Process

The manufacturing process for customized hardware involves various techniques and technologies. The exact processes used depend on the type of component being produced and the material being used. Common manufacturing processes include machining, casting, forging, and stamping.

Machining involves the use of machines to cut, shape, or remove material from a raw block to create the desired component. Casting is a process where molten metal is poured into a mold to create the shape of the component. Forging involves shaping metal by hammering or pressing it into the desired form. Stamping is a process where metal sheets are pressed through molds to create components with specific shapes and features.

Quality Assurance

Quality assurance is a crucial aspect of customized hardware production. This ensures that the components meet the specified standards and perform as expected. Quality assurance processes include testing, inspection, and certification.

Testing involves checking the components for mechanical properties, such as strength, durability, and fatigue resistance. Inspection involves examining the components for defects, such as cracks or impurities, using visual inspection or advanced techniques like X-ray or ultrasound scanning. Certification is provided when the components meet all quality standards and are safe for their intended use.

Applications

Customized hardware is used in various applications across different industries. In the construction industry, customized hardware is used in doors, windows, cabinets, and other fixtures. In the automotive industry, customized hardware is used in engines, suspension systems, and interior components. In the manufacturing industry, customized hardware is used in machines, equipment, and tooling.

The benefits of customized hardware are numerous. It allows for precise fit and function, ensuring that components work as intended without any issues. It also allows for cost optimization by eliminating the need for stock components that may not meet specific requirements. Additionally, customized hardware allows for branding and customization, adding value to products and making them unique.

Conclusion

Customized hardware has become an integral part of modern manufacturing and construction processes. It allows for precision engineering and customization, ensuring that components meet specific requirements and perform as expected. With advances in technology and manufacturing techniques, customized hardware is becoming more affordable and accessible for businesses and individuals alike.

Articles related to the knowledge points of this article:

Title: A Comprehensive Guide to Beijing Metal Die Casting Customized Services

Whole House Customization: Giant Forest Hardware

Nanjing Customized Hardware Bulk Customization