Title: Xuzhou Hardware Manufacturers: A Journey Through Their Production Process

Xuzhou hardware manufacturers have long been renowned for the quality of their products, but what is it like to visit their production process? This journey takes you through the factories and workshops, from raw material to finished product. You will witness the precision machining of metal parts, the assembly of components, and the quality control measures in place to ensure each product meets the highest standards. The journey also includes a visit to the packaging department, where products are carefully wrapped and prepared for shipment. Here, you can see the Xuzhou hardware manufacturers' commitment to quality and efficiency, which has made them a trusted name in the industry.

Xuzhou, a city in Jiangsu province, China, is renowned for its diverse industrial sectors, one of which is hardware manufacturing. The city's hardware industry has a long history dating back to the early 20th century and has since evolved to become one of the most prominent in China. Xuzhou hardware manufacturers have established a reputation for producing high-quality products that meet international standards, making them a reliable source for global markets.

In this article, we will delve into the production process of Xuzhou hardware manufacturers to explore the various stages involved in creating high-quality products. We will also discuss the unique features of Xuzhou hardware and what makes it stand out from other hardware produced in China.

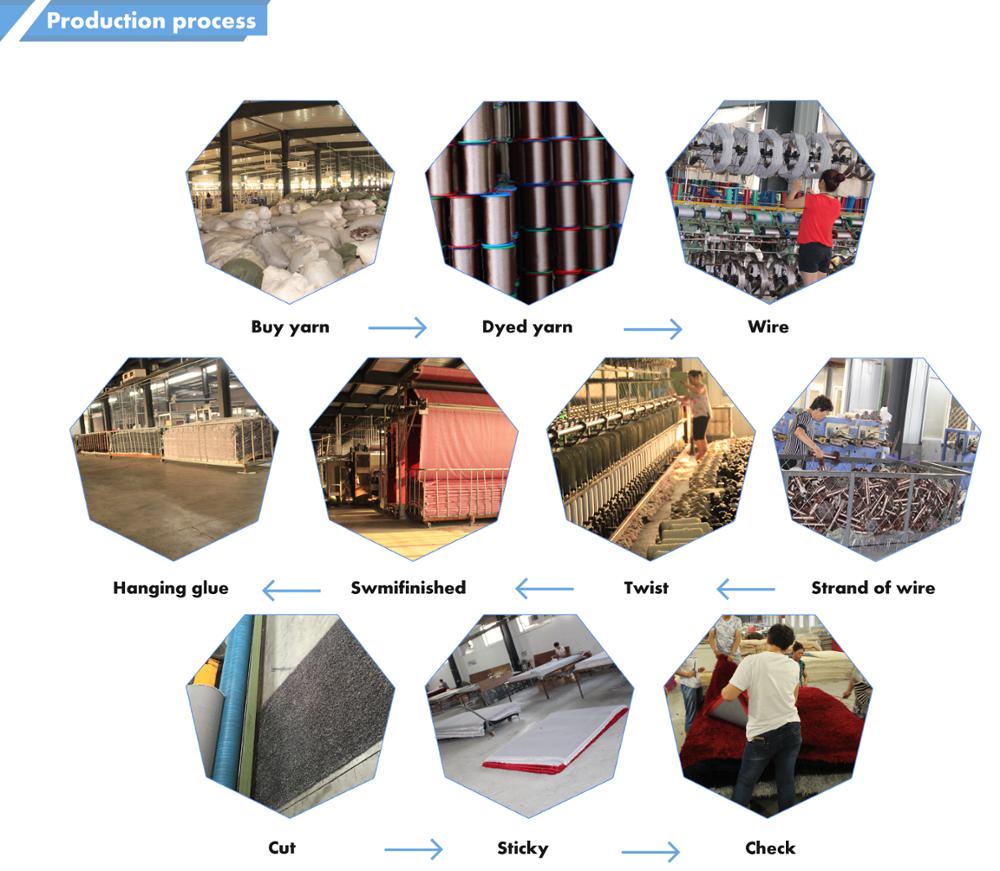

The Production Process

The production process of Xuzhou hardware manufacturers typically begins with raw material procurement. These manufacturers source high-quality raw materials from reputable suppliers to ensure the durability and performance of their products. Once the raw materials are received, they are inspected for quality and then processed to meet the specific requirements of each product.

In the next stage, the processed materials are cut and shaped using precision machines to create the desired components. This process ensures that each component is accurately sized and shaped to fit together seamlessly. Following this, the components undergo heat treatment to enhance their mechanical properties, such as hardness and strength.

Once the components have been heat treated, they are cooled and ground to achieve the desired surface finish. This process removes any imperfections on the surface of the components, ensuring that they are smooth and aesthetically pleasing. The components are then inspected again to ensure that they meet the required quality standards.

Next, the components are assembled into finished products using precision assembly machines. This process involves placing the components together in the correct order and securing them using fasteners or welding techniques. The assembled products are then inspected for quality assurance to ensure that they function properly and meet the specifications of each model.

Finally, the finished products are packaged and shipped to customers worldwide. Xuzhou hardware manufacturers use sustainable packaging materials to protect their products during transportation and ensure that they reach customers in good condition.

Unique Features of Xuzhou Hardware

Xuzhou hardware manufacturers have established a reputation for producing high-quality products that meet international standards. Their products are known for their durability, performance, and aesthetic appeal. Here are some unique features that make Xuzhou hardware stand out from other hardware produced in China:

1、Use of High-Quality Raw Materials: Xuzhou hardware manufacturers source raw materials from reputable suppliers and inspect them for quality before processing. This ensures that their products are made from high-quality materials that meet international standards.

2、Precision Cutting and Shaping: Xuzhou hardware manufacturers use precision machines to cut and shape the processed materials into the desired components. This process ensures that each component is accurately sized and shaped to fit together seamlessly, resulting in precision-crafted products with superior mechanical properties.

3、Heat Treatment and Surface Finishing: Xuzhou hardware manufacturers subject their components to heat treatment to enhance their mechanical properties, such as hardness and strength. Following this, they cool and grind the components to achieve the desired surface finish, removing any imperfections on the surface for a smooth and aesthetically pleasing appearance.

4、Quality Assurance Processes: Xuzhou hardware manufacturers have implemented rigorous quality assurance processes to ensure that their products meet the highest standards of quality. This includes inspecting each component and finished product for defects, as well as testing them under various conditions to ensure their performance and reliability.

5、Sustainable Packaging Materials: Xuzhou hardware manufacturers use sustainable packaging materials to protect their products during transportation. This ensures that their products reach customers in good condition while also reducing environmental impact.

Conclusion

Xuzhou hardware manufacturers have established a reputation for producing high-quality products that meet international standards. Their unique features, such as use of high-quality raw materials, precision cutting and shaping, heat treatment and surface finishing, quality assurance processes, and sustainable packaging materials, have made them a reliable source for global markets. As Xuzhou hardware continues to evolve and innovate, it will continue to meet the demands of customers worldwide for years to come.

Articles related to the knowledge points of this article:

Title: Decorative Hardware Manufacturers: An Introduction to Their Products and Processes

Chinese Hardware Manufacturers: Embracing Innovation and Quality to Shape the Future