The Role of a Fabrication Company in Manufacturing Pump Parts for Metal Finishing

In the manufacturing sector, fabrication companies play a crucial role in the production of pump parts for metal finishing processes. These companies specialize in the design, fabrication, and testing of these components, which are essential for the successful completion of metal finishing operations. Fabrication companies have the necessary expertise and tools to produce high-quality pump parts that meet specific technical and functional requirements.The process begins with the fabrication company receiving orders for pump parts from various clients, who require them for their respective metal finishing applications. The fabrication company then works closely with its engineers to design the pump parts according to the specifications provided by the clients. The engineers use advanced software and simulation tools to ensure that the designed parts meet all the required standards and specifications.Once the design is approved, the fabrication company moves on to the actual fabrication of the pump parts. This involves machining, grinding, polishing, and other precision techniques to create the precise shapes and dimensions required for the pump parts. The fabrication company also ensures that the parts are tested for functionality and durability before being delivered to the clients.Overall, fabrication companies play an integral role in the manufacturing of pump parts for metal finishing processes. Their expertise and dedication to delivering high-quality products to their clients make them a valuable resource in this field.

In the industrial world, precision and efficiency are often paramount considerations when it comes to the manufacturing process. For the metal finishing sector, this translates to creating parts that meet stringent standards for durability, functionality, and aesthetic appeal. One such critical component is pump components, which play a significant role in the efficient operation of machinery and systems. A specialized company, known as 'Metal Finishing Co.', specializes in the fabrication of these vital parts for various industrial applications.

At Metal Finishing Co., our commitment to excellence extends beyond mere product manufacturing. Our expertise lies in the meticulous craftsmanship that ensures every pump part meets the highest quality standards. From conceptualization to completion, we employ advanced technologies and state-of-the-art equipment to manufacture pump parts that not only function flawlessly but also last long into the future.

The process begins with a detailed design phase where our engineers work closely with clients to understand their specific needs and requirements. This stage involves considering factors like pressure, flow rate, material type, and the intended application. Based on these parameters, we develop an optimized design that balances cost effectiveness with performance.

Once the design is finalized, the next step is to produce a blueprint or schematic of the part, which will guide our production process. Using this blueprint, we then create the molds or dies required for mass production. These molds must be designed to accurately replicate the shape of the final part while ensuring consistent dimensions and precise placement of features.

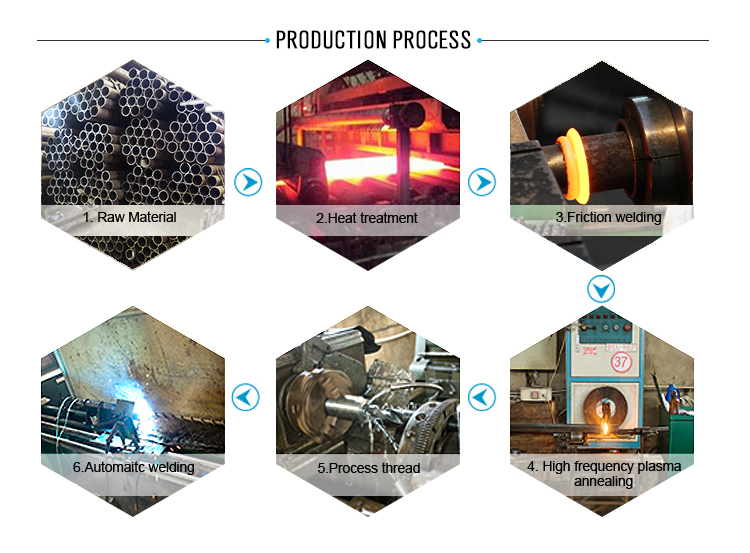

With the molds in place, we move onto the actual manufacturing process. At Metal Finishing Co., we utilize the latest techniques and equipment to produce high-quality parts. This may include casting, machining, welding, grinding, and finishing processes depending on the type of pump part being produced. Each step of the manufacturing process is carefully monitored and controlled to ensure consistency in quality and accuracy.

Our commitment to quality extends beyond just meeting client expectations; we also prioritize safety and environmental responsibility. All materials used in our processes comply with industry standards for both toxicity and sustainability. We use energy-efficient machines and implement practices such as waste minimization and recycling to minimize environmental impact.

As the manufacturing process nears its end, we undergo rigorous testing to ensure that each component meets the specified standards of strength, durability, and function. This testing includes internal pressure tests, leakage inspections, and stress analysis to guarantee the part's reliability and longevity.

Once a part passes all these tests and meets our rigorous standards, it is ready to join the pipeline towards its intended destination. From there, it can be integrated into a complete system, providing the necessary functionality for the machine or device it serves.

In conclusion, at Metal Finishing Co., we understand that the fabrication of pump parts requires a level of precision and dedication that goes beyond mere technical expertise. Our commitment to excellence, combined with a deep understanding of the market demands and client needs, has made us a trusted partner for numerous industries. With each component crafted with care by our team using state-of-the-art technology, we strive to provide solutions that enhance efficiency and productivity, thereby contributing to a better tomorrow for all those who depend on these critical parts.

Articles related to the knowledge points of this article:

Coal Mine Hardware Manufacturers

Xian Tao Hardware Manufacturers

Title: Exploring the Comprehensive Shantou Domestic Hardware Manufacturers Pricing List