Custom Slide Track Hardware: The Ultimate Guide

This ultimate guide to custom slide track hardware is designed to help you understand the intricacies of this unique hardware solution. From its definition and importance to its applications and how to choose the right one for your needs, this guide provides a comprehensive overview of all aspects related to custom slide track hardware. Firstly, we explore the definition and importance of custom slide track hardware. Essentially, it refers to a type of hardware that allows for the customization of slide tracks according to specific requirements. This level of customization significantly enhances the usability and performance of slide tracks, making them more suitable for a wider range of applications. Then, we take a look at the applications of custom slide track hardware. From industrial machinery to medical equipment, custom slide tracks are employed in numerous sectors to ensure precision, reliability, and efficiency. By understanding the different applications, you can gain a deeper insight into the role and importance of custom slide track hardware. Moreover, this guide also covers how to choose the right custom slide track hardware for your needs. With so many options available on the market, it can be overwhelming to make the right decision. However, by considering factors such as budget, requirements, and preferences, you can narrow down your choices to find the most suitable option for your project or application. In conclusion, this ultimate guide to custom slide track hardware provides a comprehensive understanding of this exciting hardware solution. From its definition and importance to its applications and how to choose the right one for your needs, this guide has everything you need to know about custom slide track hardware.

Slide track hardware is a crucial component in various applications, offering smooth and efficient linear motion. From industrial machinery to consumer products, it plays a vital role in the performance and lifespan of a device. In this article, we explore the world of custom slide track hardware, providing an in-depth understanding of its importance, designs, and applications.

What is Custom Slide Track Hardware?

Custom slide track hardware refers to slide tracks that are designed and manufactured specifically for a particular application or device. These tracks are tailored to meet the specific needs of the user, offering increased performance, durability, and reliability over standard slide tracks. By understanding the requirements of the application, custom slide track hardware can be designed to reduce friction, increase load capacity, and improve overall system efficiency.

Why Use Custom Slide Track Hardware?

There are several advantages to using custom slide track hardware in your application. Firstly, it can significantly improve the performance of the device. By tailor-making the slide track to meet the specific needs of the application, it can reduce friction, increase load capacity, and provide smoother linear motion. This can lead to increased productivity, efficiency, and overall system performance.

Secondly, custom slide track hardware can also enhance the durability of the device. By using high-quality materials and advanced manufacturing techniques, custom slide tracks can be designed to withstand high levels of stress and wear. This can extend the lifespan of the device, reducing maintenance costs and downtime.

Thirdly, custom slide track hardware can improve the reliability of the system. By ensuring that the slide track is designed and manufactured to exacting standards, it can reduce the risk of failure and improve system uptime. This can lead to increased productivity and efficiency, reducing losses and downtime.

Design Considerations for Custom Slide Track Hardware

When designing custom slide track hardware for your application, there are several key considerations that should be taken into account. Firstly, you need to ensure that the design is suitable for the load capacity and linear motion requirements of the application. This will determine the size, shape, and material of the slide track to be used.

Secondly, you should consider the environmental conditions in which the slide track will be operating. This includes temperature, humidity, and any other factors that may affect the performance or lifespan of the hardware. By taking these factors into account, you can ensure that the design is suitable for its intended environment.

Thirdly, it is important to consider the budget and cost-effectiveness of the design. By balancing the need for performance and durability with the cost of manufacturing, you can achieve a design that offers good value for money.

Applications for Custom Slide Track Hardware

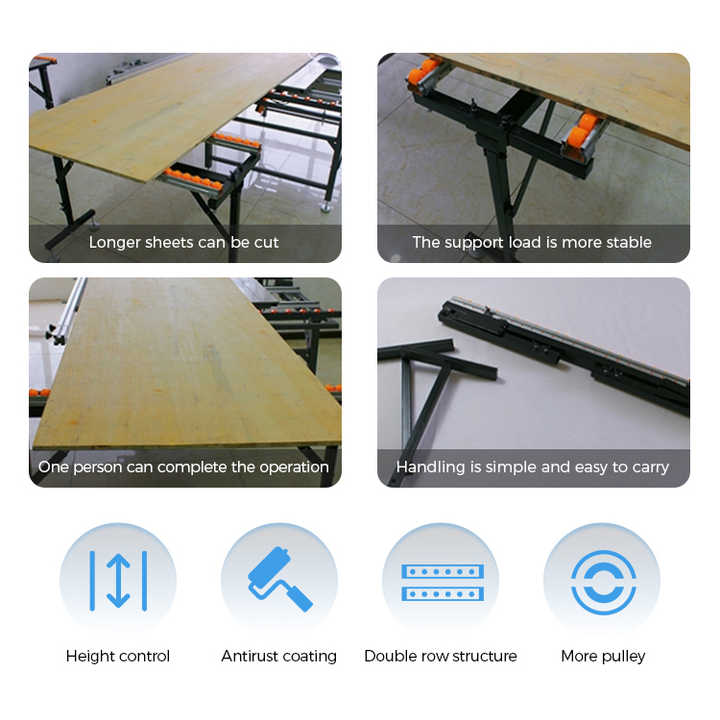

Custom slide track hardware has numerous applications in various industries and consumer products. In industrial machinery, it is often used in machining centers, CNC routers, and laser cutting machines to provide smooth linear motion for cutting tools or workpieces. In automotive applications, custom slide tracks may be used in door systems, windows, or even electric vehicles to provide smooth linear motion for opening and closing components.

In consumer products, custom slide track hardware may be found in office chairs, sliding drawers, or even toy cars to provide smooth linear motion for user convenience or play functionality. By understanding the specific needs of each application or device, custom slide track hardware can be designed to meet those needs effectively and efficiently.

Conclusion

Custom slide track hardware offers numerous advantages over standard slide tracks in terms of performance, durability, and reliability. By taking into account design considerations such as load capacity requirements, environmental conditions, and budget cost-effectiveness; you can achieve a design that offers good value for money while meeting the specific needs of your application or device effectively and efficiently.

Articles related to the knowledge points of this article:

Title: The Pros and Cons of Customized Furniture with Self-bought Hardware

Large Hardware Customization Shop: A Case Study in Craftsmanship and Innovation