Title: Five-Metal Fittings Process

This article introduces the process of manufacturing five-metal fittings, which are widely used in various industries. The process involves cutting, bending, and welding of metals to produce the desired shapes and sizes. The choice of metals used in this process is crucial for achieving the desired mechanical properties and thermal stability. The manufacturing process is controlled by strict quality standards to ensure that the fittings meet the requirements of various applications. The final product is inspected and tested to ensure its performance and reliability. The process described in this article provides a general understanding of how these fittings are made and the factors that affect their quality.

The five-metal fittings process is a crucial manufacturing process in various industries. It involves the use of five different metals to create fittings that are strong, durable, and capable of withstanding harsh conditions. The process begins with the selection of the appropriate metals for the job, followed by cutting, shaping, and assembling the pieces to create the desired fitting. Finally, the fitting is inspected for quality assurance before being shipped to the customer.

In this article, we will discuss the five-metal fittings process in detail, providing a thorough understanding of each step involved. We will also highlight the importance of using high-quality metals and employing skilled craftsmen to ensure the production of top-quality fittings.

Metals Used in Five-Metal Fittings Process

The five metals commonly used in the five-metal fittings process are steel, stainless steel, brass, bronze, and aluminum. Each metal has its own unique properties that make it suitable for specific applications. For example, steel is strong and ductile, making it ideal for creating fittings that need to withstand high pressures or have a long lifespan. On the other hand, stainless steel is resistant to corrosion and heat, making it perfect for harsh environments. Brass and bronze are both non-ferrous metals that have good mechanical properties and are often used in decorative fittings. Finally, aluminum is lightweight yet strong, making it a good choice for applications where weight is a concern.

Cutting and Shaping Process

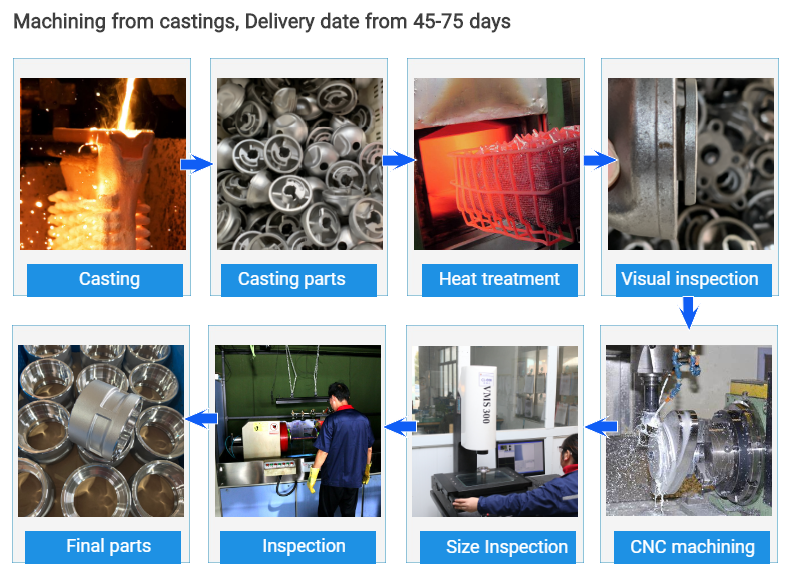

Once the appropriate metals have been selected, the cutting and shaping process begins. This step involves using various cutting tools to remove excess material from the metal pieces, creating the desired shape or profile. The cutting process can be done manually or using CNC machines, depending on the complexity of the shapes involved. After cutting, the pieces are inspected for any defects or irregularities before proceeding to the next step.

Assembling Process

In this step, the cut and shaped pieces are assembled together to create the final fitting. This can be done using various methods such as welding, soldering, or using fasteners like screws or bolts. The assembly process should be done with precision to ensure that the final product is accurate and meets all specifications. Additionally, skilled craftsmen should be employed to ensure that the assembly process is done correctly and efficiently.

Quality Assurance Inspection

Once the assembling process is completed, the final product undergoes a quality assurance inspection to ensure that it meets all standards and customer requirements. This inspection involves checking for defects like cracks, leaks, or loose parts. If any defects are found, they should be immediately addressed and corrected before shipping the product to the customer.

In conclusion, the five-metal fittings process is a crucial manufacturing process that requires skill and precision to ensure top-quality products are produced consistently. By understanding each step involved in this process and employing skilled craftsmen to execute it properly, manufacturers can ensure that they meet their customer’s expectations every time.

Articles related to the knowledge points of this article:

Top 10 Hardware Accessories for Wardrobes

Guangzhou Furniture Hardware Accessories Market

Title: Spring Breeze Hardware Store: Your One-Stop Shop for All Metal Components in Wuhan

Title: Understanding the Prices of Metal Hardware Accessories in Guiyang

Title: Direct Sales Price for High-Quality Metal Hardware in Jilin Province