Custom Hardware Applications: The Future of Product Design

The future of product design is moving towards Custom Hardware Applications. With the increasing demand for personalized and customized products, the need for tailor-made hardware solutions is also growing. Custom Hardware Applications offer numerous advantages such as increased efficiency, improved performance, and better user experience. By allowing designers to create products that perfectly fit the specific needs of their target audience, these applications enable them to create products that are not only unique but also highly functional. From smartphones to computers, Custom Hardware Applications are changing the way we design and manufacture products. They are revolutionizing the industry by providing designers with the tools and resources they need to create truly innovative and practical solutions. In the future, Custom Hardware Applications will continue to grow in popularity as designers and manufacturers look for ways to differentiate their products and meet the demands of their customers.

With the evolution of technology, the demand for customized hardware applications has skyrocketed. From consumer electronics to industrial machinery, tailor-made hardware solutions are revolutionizing the way products are designed and manufactured. In this article, we explore the trend of customization in hardware applications and how it is changing the landscape of product design.

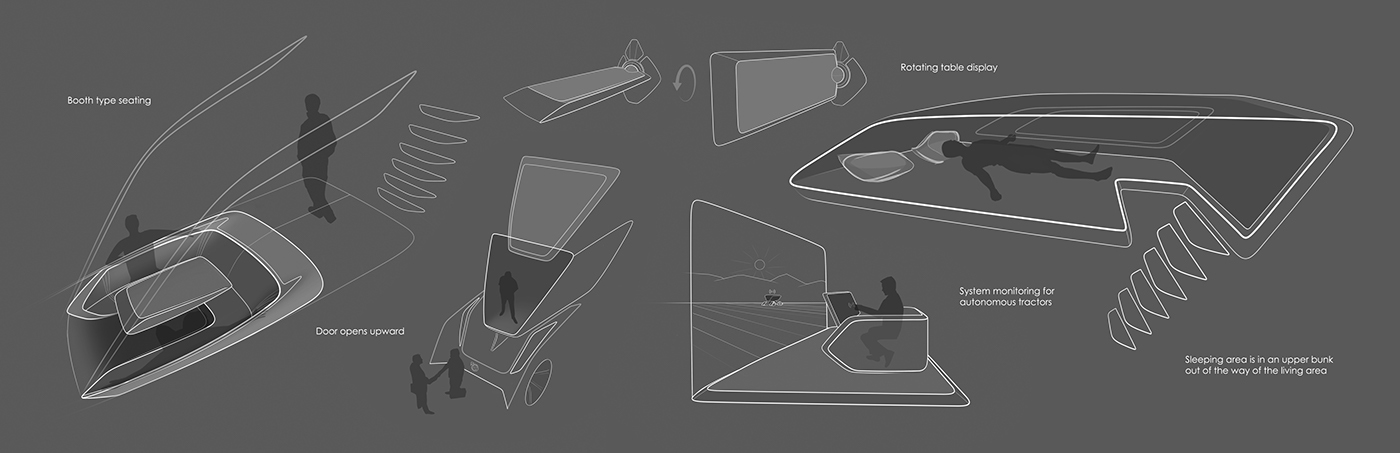

Consumer electronics are among the first sectors to embrace customized hardware solutions. From smartphones to tablets, users now have the option to tailor their devices to their specific needs. For instance, someone who frequently travels may opt for a lightweight, foldable device that fits easily into a backpack, while someone who stays at home most of the time may choose a larger, more powerful device with a longer battery life. This level of customization not only meets user needs but also adds value to the product.

Another area where customized hardware applications are making a significant impact is in industrial machinery. Traditional industrial equipment was designed to perform specific tasks using standardized parts and components. However, with the advent of additive manufacturing and intelligent materials, it is now possible to create machines that are tailored to individual businesses or even specific tasks. This approach significantly enhances productivity and efficiency by reducing the need for maintenance and improving overall performance.

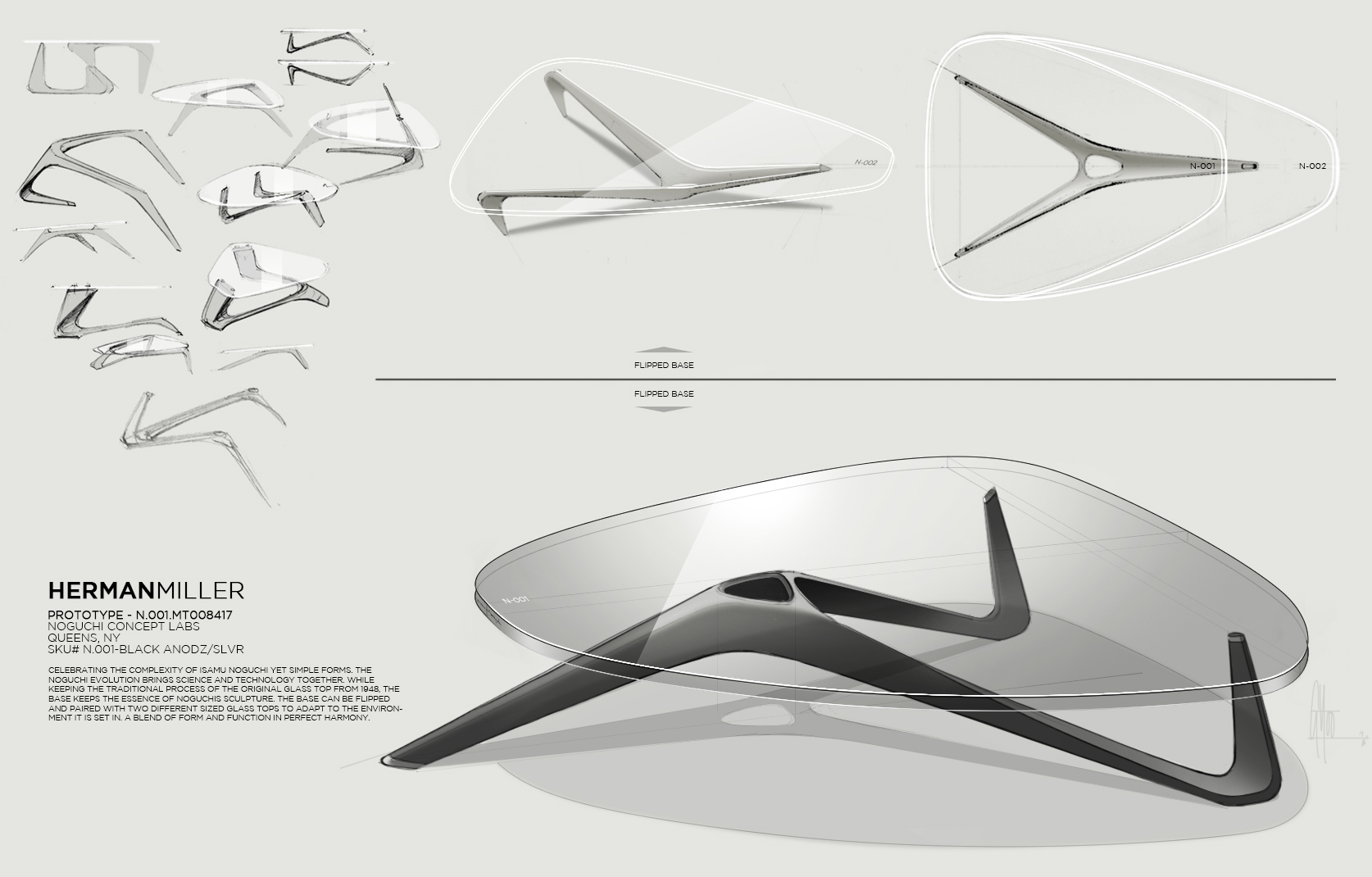

Moreover, customized hardware applications are changing the way products are designed and manufactured. Instead of relying solely on conventional manufacturing techniques, designers now have access to a range of advanced technologies that enable them to create products that are not just functional but also unique and attractive. From 3D printing to nanotechnology, these technologies are being used to create products that are lightweight, strong, and have an increased level of detail and precision.

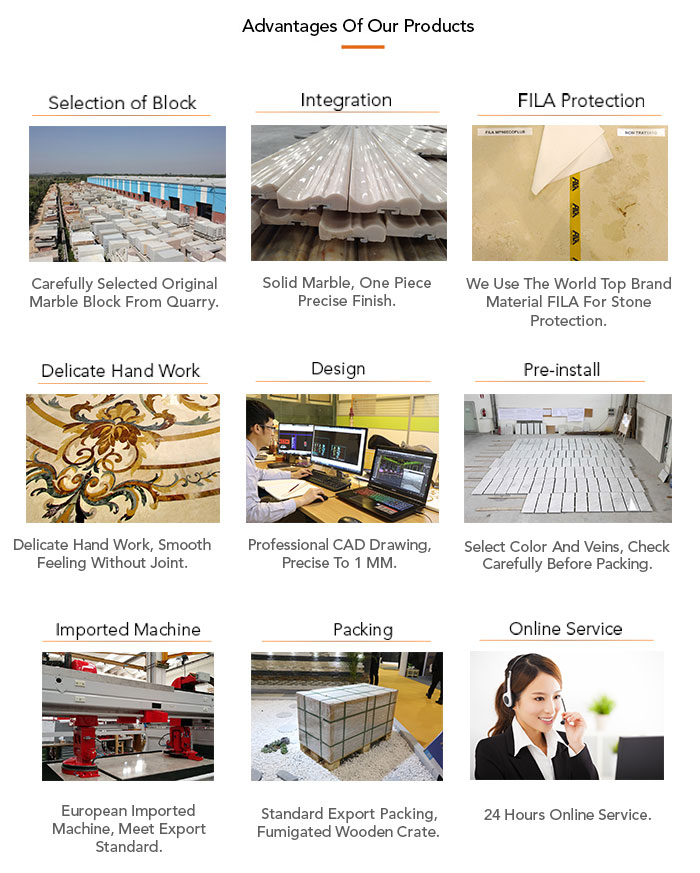

Moreover, customized hardware solutions are enabling businesses to reduce their environmental footprint. By creating products that are tailored to specific needs, businesses can reduce the number of unnecessary components and materials used, thus reducing waste and pollution. This approach is particularly beneficial for industries that have traditionally been heavy users of resources, such as the automotive or aerospace industries.

However, while customized hardware applications have brought about significant benefits, there are also challenges that need to be addressed. One major concern is the issue of scalability. While it is relatively easy to create small batches of customized products, scaling up to meet large-scale demand can be challenging. Additionally, there is the issue of cost. While customized hardware solutions may initially cost more than off-the-shelf products, in the long run, they could save businesses significant amounts of money by reducing maintenance and operational costs.

In conclusion, customized hardware applications are changing the landscape of product design in significant ways. By offering increased levels of personalization and customization, these solutions are meeting user needs and adding value to products. However, there are also challenges that need to be addressed, such as scalability and cost. As these issues are addressed, we can expect customized hardware applications to become even more prevalent in future product designs.

Articles related to the knowledge points of this article:

Custom Hardware Market in Linyi: A Comprehensive Overview

Title: Precision Hardware Production for Furniture Batch Manufacturing

Guangdong Mango Hardware Customization: Quality and Service for Your Project

Title: Customizing Hardware Intra-Pallet Trays in Hunan Province: A Comprehensive Guide