A Comprehensive Guide to Custom Hardware Factory Production Tables

This comprehensive guide to custom hardware factory production tables provides an in-depth understanding of the various components, design principles, and manufacturing processes involved in creating customized tables. The guide covers topics such as choosing the right materials, designing the table's layout and dimensions, selecting appropriate tools and equipment, and implementing quality control measures to ensure precision and durability. Additionally, it includes tips for managing inventory, optimizing production processes, and reducing waste. This guide is designed for those who are interested in building or upgrading custom hardware factory production tables, whether for their own business or as a valuable resource for others.

Introduction:

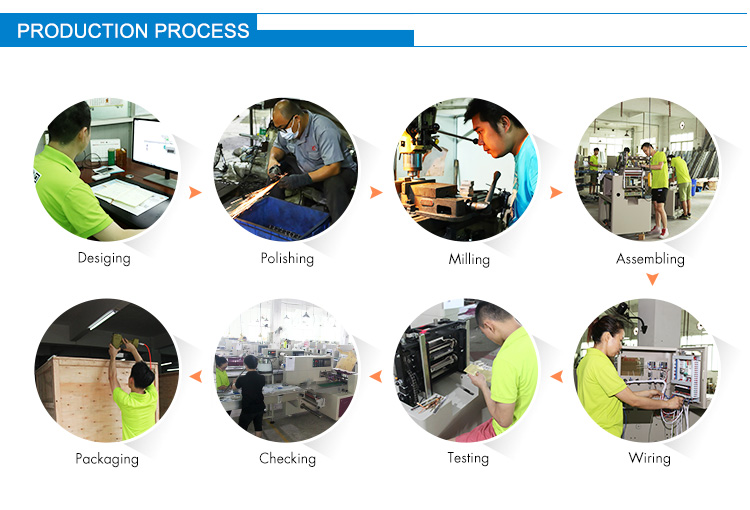

Custom hardware manufacturing is a crucial aspect of the industrial sector, as it enables businesses to produce products tailored specifically to their needs. One of the critical steps in this process is ensuring that each product is accurately measured and assembled with precision. This necessitates the use of specialized tools such as factory production tables, which are designed for precise measurement and assembly of various components. In this article, we will provide an overview of the different types of custom hardware production tables available and offer tips on selecting the appropriate table for your specific needs.

Types of Custom Hardware Production Tables:

There are several types of custom hardware production tables available in the market, each with its unique features and benefits. Here are some of the most common types:

1、Flatbed Tables:

Flatbed tables are the most common type of production table used in the industry. They feature a smooth and flat surface that allows for easy alignment and measurement of components. These tables can be customized to fit any size or shape of components, making them ideal for mass production settings.

2、Adjustable Tables:

Adjustable tables offer more flexibility in terms of component placement and orientation. They can be adjusted to accommodate various sizes and shapes of components, making them suitable for niche markets or custom-tailored designs.

3、CNC-Equipped Tables:

CNC (Computer Numerical Control)-equipped tables are designed for high-precision assembly operations. They feature advanced CNC technology that allows for precise cutting and machining of components, resulting in tighter tolerances and better overall quality. These tables are typically used in industries requiring high precision and reliability, such as automotive, electronics, and medical equipment.

4、Multifunctional Tables:

Multifunctional tables are designed to perform multiple tasks at once. They may include features like adjustable height, rotating platforms, or integrated lighting systems, allowing for a more efficient and streamlined workflow.

5、Mobile Tables:

Mobile tables are designed to be portable and easy to move around the work area. They are perfect for small workshops or remote locations where space is limited.

Selecting the Right Production Table:

When selecting a custom hardware production table, there are several factors to consider, including the size and shape of the components you will be working with, your budget, and your specific needs. Here are some tips to help you make an informed decision:

1、Alignment:

Make sure the table is aligned correctly to prevent errors during assembly. Consider the angle of tilt, the distance apart, and the positioning of the table's legs or feet.

2、Accessibility:

Ensure that the production table is easy to access and maneuver. Consider the size of the work area and the placement of other equipment to avoid clutter and make it easier to move around the table quickly.

3、Material and Quality:

Choose a table that is made from durable and high-quality materials. Look for tables that are designed for precision and accuracy to ensure longevity and reliability.

4、Features:

Determine if additional features are necessary based on your needs. For example, if you require precision machining or CNC capabilities, look for tables equipped with these features.

5、Cost:

Compare prices and features of different production tables to find the best value for your budget. Consider the cost of maintenance, repair, and replacement parts over time.

Conclusion:

The right custom hardware production table is essential for achieving high-quality products within the shortest possible timeframe. By understanding the various types of tables available, considering factors such as alignment, accessibility, material quality, and features, and comparing prices and features, you can select the best production table for your specific needs. Remember, investing in the right tool will not only improve efficiency but also enhance overall productivity and customer satisfaction.

Articles related to the knowledge points of this article:

Custom Hardware Manufacturing: A Look Inside the Factory

Title: Custom Hardware Solutions: The Art of Creating High-Quality Hardware in Humen

TianTai High-End Customized Hardware: Quality and Precision At Its Finest

Title: Custom Hardware Solutions in Taizhou, China

Title: Customized Brass Hardware Manufacturing and Pricing - A Comprehensive Guide