Custom Fabrication of Hardware in the Factory

The factory has the ability to customize hardware fabrication based on individual needs. This ensures that each customer receives the exact product they want, tailored to their specific application or design. The fabrication process starts with the selection of raw materials, which are then processed through machines to create the desired shape or structure. Quality control measures are in place to ensure that each product meets the required standards and specifications. Custom fabrication allows for more creativity and flexibility in product design, making it possible to create unique solutions for unique problems. Whether it's a simple hardware component or a complex machine, the factory can provide the perfect solution to meet your needs.

The process of custom fabricating hardware in a factory is a crucial aspect of the manufacturing industry. This involves the creation of metal components and assemblies that are tailored to meet the specific needs of a particular application or device. In this article, we explore the essential steps and considerations involved in custom hardware fabrication.

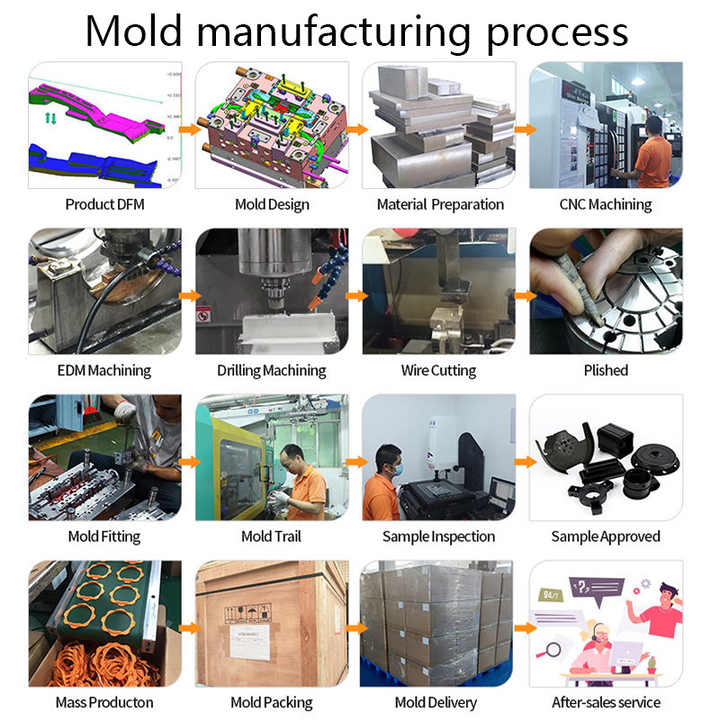

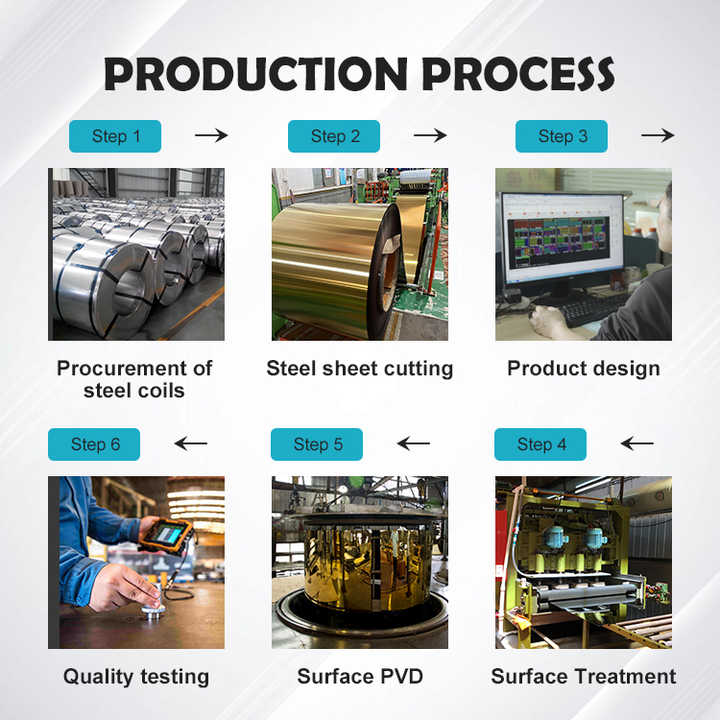

Firstly, the design phase is crucial. This is when the factory identifies the specific requirements of the hardware to be fabricated. This may include the shape, size, material, and performance characteristics needed for the application. The factory then creates a detailed design that outlines the shape and dimensions of the hardware, as well as any specific features or modifications required.

Once the design is approved, the factory moves into the cutting phase. This involves using cutting tools or machines to shape the raw material into the desired form. The factory ensures that the cutting process is precise and accurate to ensure that the hardware meets the design specifications.

Next, the factory performs the machining process. This involves using machines such as lathes, mills, and grinders to further shape and refine the hardware. The machining process allows for the creation of complex shapes and features that may not be possible through simple cutting alone.

Once the machining process is completed, the factory moves into the assembly phase. This is when the various components and assemblies are brought together to form the final hardware product. The factory ensures that the assembly process is precise and that all components are properly aligned and secured.

Finally, the factory performs quality control checks to ensure that the custom hardware meets all specifications and standards. This may involve measuring dimensions, testing performance characteristics, and inspecting for defects or impurities.

In conclusion, custom fabricating hardware in a factory requires a series of precision-oriented steps and considerations. From the design phase to the final quality control check, each step must be carefully executed to ensure that the hardware meets the specific needs of the application or device. The factories that excel in this process are those that can deliver high-quality, cost-effective solutions that meet or exceed customer expectations.

Articles related to the knowledge points of this article:

Custom Bus Door Hardware for the Whole House

Customized Hardware for Entire House: Providing a Personalized Touch to Your Home

Title: Custom Hardware Pricing in Huizhou: A Comprehensive Guide