Customizing Hardware Parts: The Art of Tailor-Made Solutions

"Customizing Hardware Parts: The Art of Tailor-Made Solutions"This paper delves into the art of customizing hardware components, focusing primarily on the process of creating tailor-made solutions for specific applications. It emphasizes the importance of understanding the requirements and constraints of the intended use, as well as the potential limitations of existing hardware designs. By taking a tailored approach to hardware design, engineers can optimize performance, reduce costs, and enhance user experience.The discussion also highlights the need for collaboration between hardware designers and users, who must work together to ensure that the final product meets all necessary functional and aesthetic criteria. This requires a deep understanding of both the hardware components involved and their potential impact on the overall system.Ultimately, the goal of customizing hardware parts is to create solutions that are uniquely suited to the needs of each individual application, while still maintaining a high degree of reliability and durability. Through careful consideration of all relevant factors, engineers can craft truly bespoke hardware solutions that meet even the most demanding of requirements.

Introduction:

In the ever-evolving world of industrial production, precision and functionality often dictate the success of any project. One area where these principles shine through is in the realm of hardware customization, where specialized machinery is designed to meet unique needs and specifications. At the heart of this process lies the art of custom hardware part manufacturing, where each part is crafted from scratch with the specific requirements of a client or project in mind. In this article, we explore the complexities and benefits of customizing hardware parts, delving into the techniques, considerations, and the end results that make this process not just functional but truly exceptional.

Techniques for Custom Hardware Part Manufacturing:

The process of crafting custom hardware parts begins with thorough planning and analysis. This involves understanding the intended purpose, size, shape, material, and performance criteria of the part. The next step is designing the part based on these factors. Here, the expertise of engineers and designers comes into play, using advanced software tools and simulation technologies to create a blueprint that will guide the manufacturing process.

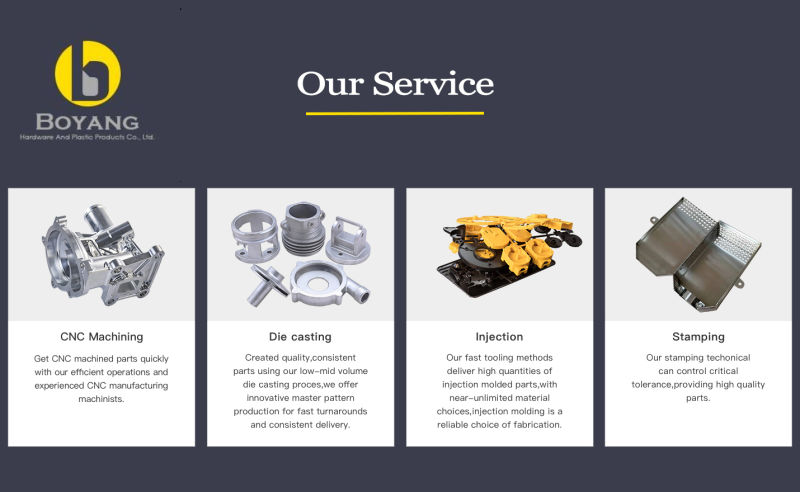

Once the design is finalized, the manufacturing phase begins. Depending on the complexity of the part, it may involve several stages such as machining, grinding, polishing, welding, or even CNC (Computer Numerical Control) programming. The choice of technology will largely determine the precision and speed of the process, with CNC being particularly useful for intricate designs requiring high accuracy.

Material Choices:

When selecting the right material for a custom hardware part, it is important to consider its strengths, durability, resistance to wear and tear, and compatibility with the intended application. For instance, stainless steel is commonly used for applications requiring corrosion resistance, while aluminum alloys offer light weight and good heat conductivity. Moreover, there are many composite materials available that combine the best properties of two or more different materials to produce a unique combination that offers superior performance.

Considerations:

One of the most significant challenges in custom hardware part manufacturing is ensuring that the finished product meets or exceeds customer expectations. This requires careful attention to detail, meticulous testing, and continuous improvement. Additionally, ethical considerations must also be taken into account, including environmental impact and fair labor practices. It's essential to maintain transparency throughout the entire process, from design to delivery, so customers can trust that their investment in custom hardware is secure and sustainable.

Benefits of Custom Hardware Parts:

Custom hardware pieces have numerous advantages over standard products, ranging from increased functionality to improved safety. By tailoring the design and features to specific applications, custom parts offer unparalleled precision, reliability, and adaptability. They can also reduce maintenance costs by being less prone to wear and tear, offering a longer lifespan for the equipment they support. Furthermore, customized hardware pieces can enhance operational efficiency by reducing downtime due to faulty components or worn-out gears.

Conclusion:

Custom hardware parts manufacturing is a sophisticated and demanding process that demands both technical expertise and creative vision. Through thoughtful planning, precise execution, and continuous improvement, businesses can realize significant cost savings and enhanced productivity while delivering exceptional value to their clients. As the demand for custom solutions continues to grow, the importance of investing in custom hardware manufacturing cannot be overstated. In the future, it is likely that this field will continue to evolve, embracing emerging technologies and materials to push beyond the boundaries of what was once deemed impossible.

Articles related to the knowledge points of this article:

Title: The Art of Customizing Metal模具货架 - A Comprehensive Guide

Top 10 Hardware Brands for Custom Furniture in 2023

Custom Metal Plate Images: Creating, Benefits, and Uses

Customized Hardware Shelves in Ningbo: The Ultimate Guide

Title: Customize Your Lv Hardware to Perfection: A Guide to Crafting Stunning Lv Accessories