Custom Metal Fabrication: A Detailed Guide to the Process

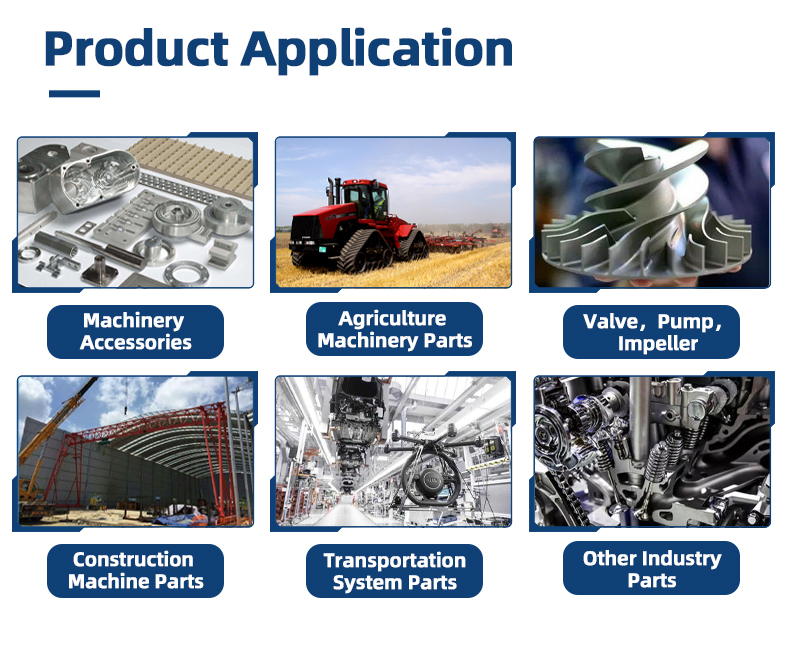

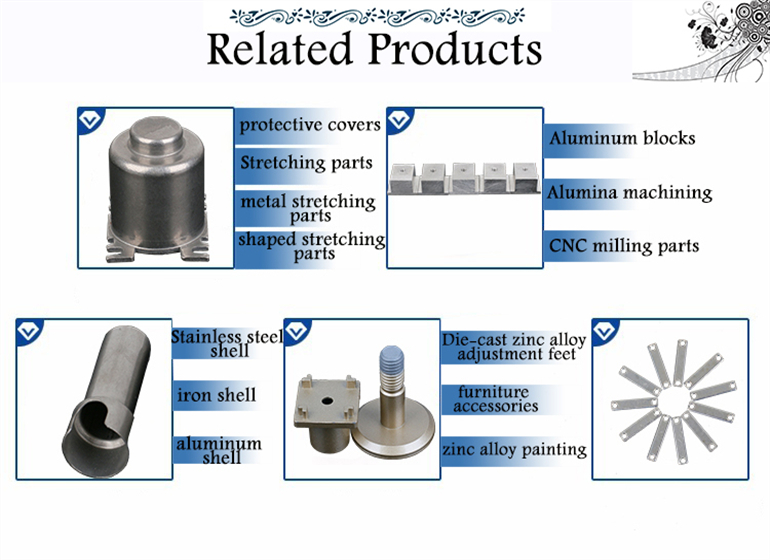

Custom Metal Fabrication: A Detailed Guide to the ProcessCustom metal fabrication is a process that involves the cutting, bending, welding, and finishing of metal materials to create unique and specialized products. This guide provides a detailed overview of the process to help you understand how it works and how it can benefit your business or project.Firstly, the process starts with the selection of suitable metal materials based on their mechanical properties, durability, and cost-effectiveness. Then, using advanced cutting techniques like laser cutting or waterjet cutting, the metal is cut into the desired shapes and sizes. This ensures precision and accuracy in the final product.Once the metal pieces are cut, they are then bent or formed into the desired shape using bending machines or forming presses. This step is crucial in creating complex shapes and designs that cannot be achieved through simple cutting techniques.After bending, welding is often used to join the metal pieces together to create a single, strong structure. Different welding techniques like arc welding or laser welding can be used based on the specific requirements of the project.Finally, the fabricated metal product is finished to ensure its smooth operation and longevity. This may involve deburring, polishing, and coating the surface to protect it from corrosion or wear and tear.In conclusion, custom metal fabrication is a highly specialized process that requires precision and skill to achieve the desired results. By understanding the process and its benefits, you can make better decisions when it comes to your business or project needs.

Metal fabrication, also known as "定制五金施工", is a crucial aspect of many construction and industrial projects. It involves the process of cutting, shaping, and joining metal materials to create a desired structure or product. In this article, we explore the essential steps and considerations involved in custom metal fabrication to help you understand the process better.

Step 1: Understanding the Project Requirements

The first step in any metal fabrication project is to fully understand the requirements of the job. This includes determining the shape, size, and type of metal needed to complete the project. For example, a construction project may require steel beams for support or copper pipes for plumbing. The fabricator needs to know these details to quote the job accurately.

Step 2: Designing the Fabrication Plan

Once the project requirements are clear, the next step is to design a fabrication plan. This plan outlines the specific steps needed to create the desired metal structure or product. It includes the cutting, shaping, and joining processes that will be used. The fabricator will provide a detailed drawing or model to ensure everyone is on the same page.

Step 3: Preparing the Metal Materials

Before any cutting or shaping can occur, the metal materials must be prepared. This may involve cleaning the metal to remove any impurities or coatings, cutting it to size using a plasma cutter or laser cutter, and shaping it using a brake press or rolling machine. The level of preparation depends on the specific project requirements.

Step 4: Cutting and Shaping the Metal

Once the metal materials are prepared, the cutting and shaping process can begin. This step requires precision and skill to ensure the metal is cut and shaped accurately. The fabricator will use a variety of tools and techniques to achieve the desired results, such as using a laser cutter for precise cutting or a brake press for bending metal.

Step 5: Joining the Metal Pieces

After the metal has been cut and shaped, the next step is to join the pieces together to create the final structure or product. This may involve welding, soldering, or using fasteners like screws or bolts to hold the pieces in place. The fabricator will ensure that the joints are strong and secure to ensure the integrity of the final product.

Step 6: Finishing and Inspecting the Product

Once the metal has been joined, the finishing and inspecting process can begin. This step involves adding any necessary coatings or finishes to protect the metal from corrosion or wear, and inspecting the product for any defects or imperfections. The fabricator will ensure that the product meets all quality standards and specifications before it is shipped to the customer.

In conclusion, custom metal fabrication is a complex but essential process in many construction and industrial projects. By understanding the project requirements, designing a fabrication plan, preparing the metal materials, cutting and shaping them accurately, joining them together securely, and finishing them properly, a fabricator can create a high-quality product that meets customer needs and expectations.

Articles related to the knowledge points of this article:

Title: Elevating Home Decor with Customized Bronze Furniture Hardware

Customizing Hebei Hardware Sheet Metal Parts

Title: Customized Hardware Sales in Suzhou: Current Prices and Trends

Guangxi Wujing Custom Factory: Quality Customization for Your Needs