Customized Furniture Export Procedures

"Customized Furniture Export Procedures: An In-depth Analysis"The global furniture industry has witnessed a surge in demand for customized products, driven by consumers' preference for unique and personalized furnishings. This essay aims to provide a comprehensive analysis of the export procedures involved in custom furniture manufacturing.The first phase involves the design phase, where furniture designers work closely with clients to create bespoke pieces that meet their specific needs. The design process often includes detailed sketches, 3D models, and physical samples to ensure accuracy and functionality.Once the design is finalized, the next step is the production phase, which involves selecting the appropriate materials, tools, and techniques to manufacture the custom furniture. Quality control measures must then be implemented during this stage to ensure that the finished product meets the client's requirements and exceeds expectations.After production is completed, the final stage is packaging and shipping, which require careful consideration to minimize damage during transit. Customs clearance and documentation are also crucial steps in ensuring that the export process proceeds smoothly.In conclusion, the export of customized furniture requires a meticulous planning and execution of each stage of production. It is important to maintain communication with clients throughout the process to ensure that they receive high-quality products that meet their unique needs.

Introduction to Customized Furniture Export: The Journey from Design to the International Market

Custom furniture export is a multifaceted process that requires meticulous planning and execution from the outset. From conceptualization, design, sourcing materials, manufacturing, to final assembly and packaging, each step must be executed with precision to ensure the end product meets global standards and customer expectations. In this article, we will delve into the key steps of customized furniture export, covering everything from initial research and design, to final shipment and beyond.

1、Research and Planning

The first step in any successful export endeavor is thorough market research. Companies need to understand the target markets' cultural nuances, consumer preferences, and regulatory frameworks. They should also analyze the competitive landscape by assessing their competitors' strengths and weaknesses. With this information at hand, companies can develop a comprehensive export strategy that outlines the goals, objectives, and timelines for their custom furniture export program.

2、Design and Development

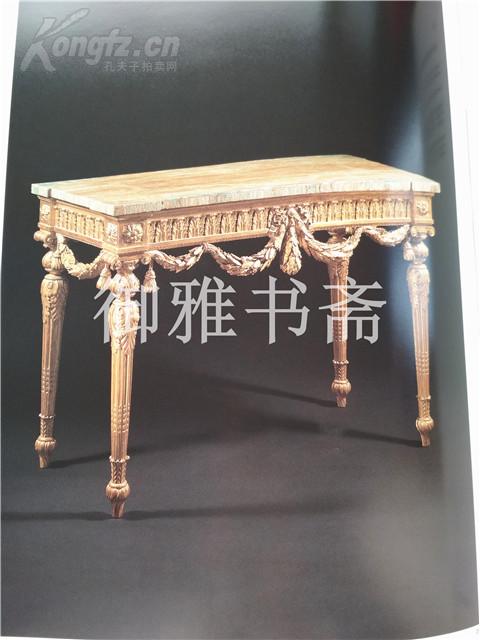

Once a plan has been developed, the next stage involves designing and developing custom furniture that meets international standards. This involves collaborating with local designers or consultants who are familiar with the target markets' aesthetics and functional requirements. The designs should be innovative yet practical, ensuring they appeal to customers while meeting their needs. The development phase may involve prototyping, testing, and iterative refinement until the final product is ready to be exported.

3、Sourcing Materials

The success of a custom furniture export project depends on the quality and reliability of the materials used. Companies must source materials from trusted vendors who can deliver consistent performance at competitive prices. This may include selecting materials such as hardwood, metal, plastic, or fabrics that are both durable and aesthetically pleasing.

4、Manufacturing

Once the materials arrive, the next step is to manufacture the custom furniture. This involves coordinating with skilled craftsmen or factories in different countries to ensure the highest levels of quality control are maintained throughout the production process. Quality checks should be conducted on every step of the manufacturing process, including inspection of finished products before dispatch.

5、Packaging and Shipping

Proper packaging is crucial for ensuring the safety and integrity of the custom furniture during transportation. Companies must choose packaging materials that are both sturdy enough to withstand shipping stress and visually appealing to attract potential buyers. Shipping arrangements should be made in advance to ensure the products are delivered on time and without damage.

6、Customs Clearance and Logistics

Customs clearance is another critical component of the export process. It involves submitting necessary documents and following customs regulations to clear customs and avoid delays or additional fees. Additionally, efficient logistics are essential for ensuring timely delivery to customers worldwide. This includes selecting reliable transportation partners, arranging for insurance coverage, and managing inventory effectively.

7、Customer Service and After-Sales Support

After the custom furniture is delivered to customers, excellent customer service and after-sales support are essential to build long-term relationships. Companies should provide detailed product manuals, installation guides, and technical support to ensure customers have all the necessary tools and resources to use the furniture effectively. Providing regular feedback loops allows companies to identify areas for improvement and address any issues promptly.

8、Marketing and Sales

Finally, marketing and sales play a significant role in driving sales for custom furniture export businesses. Companies need to establish a strong online presence through social media, e-commerce platforms, and SEO optimization. They should also organize trade shows, exhibitions, and events to showcase their products and network with potential customers. Promotional campaigns should be tailored to target specific markets and incorporate local cultural elements to increase brand recognition.

Conclusion: Enhancing the Success of Customized Furniture Export

Exporting custom furniture successfully requires a comprehensive approach that encompasses research, planning, design, material selection, manufacturing, packaging, customs clearance, logistics, customer service, and marketing. By following these steps carefully and working closely with stakeholders from the design team, manufacturers, suppliers, and logistics providers, companies can create high-quality custom furniture that resonates with global consumers. As demand for unique and stylish furniture continues to grow, investing in effective export processes ensures that companies can tap into new markets, expand their reach, and achieve long-term success in today's global marketplace.

Articles related to the knowledge points of this article:

Custom Cabinet Import Hardware

Custom Home Hardware: A Guide to Selecting and Installing Quality Hardware for Your Home

Title: Custom Processing of Non-standard Hardware in Xiamen

Miyun Hardware Customization Factory: Quality Customization for All Your Hardware Needs