Exploring the World of Precision CNC Supply in the Hardware Trade

"The Hardware Trade: An Overview of Precision CNC Supply in the World of Hardware Trading"In the realm of hardware trading, precision CNC (Computer Numerical Control) supply has become a crucial aspect. As technology advances, precision CNC systems have emerged as an essential tool for manufacturing and engineering industries that demand high precision and accuracy. This paper aims to explore the significance of precision CNC supply in the hardware trade, focusing on its impact on manufacturing, engineering, and other related sectors.Precision CNC supply plays a vital role in enhancing efficiency and reducing errors in hardware production. It enables manufacturers to produce products with precise dimensions, shapes, and sizes, leading to better quality and customer satisfaction. The use of CNC systems also reduces the need for manual labor, resulting in higher productivity and reduced labor costs.Moreover, precision CNC supply is essential for modern-day engineering and design. With the help of CNC machines, engineers can create intricate designs and models with ease, saving time and resources. This has led to increased innovation and development in various fields, including aerospace, automotive, and electronics.In summary, precision CNC supply is an essential part of the hardware trade that plays a significant role in manufacturing, engineering, and design. Its importance cannot be overstated, and it continues to drive technological advancements and innovation in various industries.

Introduction

In a world where technology is constantly evolving, precision and efficiency are paramount for businesses seeking to stay competitive. The field of CNC (Computer Numerical Control) manufacturing stands at the heart of these advancements, with its focus on precise machining that allows for intricate workpieces to be produced with unmatched accuracy. As the demand for high-quality hardware products continues to surge, the importance of reliable CNC supply chains cannot be overstated. This guide will delve into the intricacies of CNC wholesale and how it contributes to the thriving industry of hardware production.

The Basics of CNC Supply

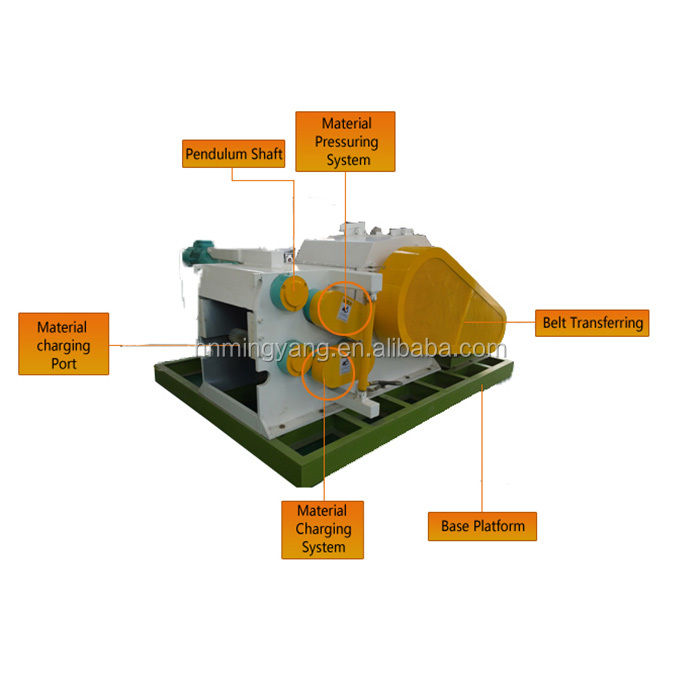

A CNC machine, short for Computer Numerical Control Machine, is a type of machine tool that uses computer-controlled movements to perform complex tasks, often including cutting, grinding, and drilling. These machines offer significant advantages in terms of speed, accuracy, and repeatability, making them ideal for producing parts with intricate designs or high volumes of work.

CNC supply refers to the range of products that manufacturers purchase from suppliers to meet their specific needs. It encompasses everything from raw materials like metal, plastics, and composites to finished products like screws, bolts, and gears. When it comes to CNC supply, there are several crucial elements to consider:

1、Raw Materials: These are the building blocks for your product. They can range from standardized components to customized pieces made from rare or exotic materials. Choosing appropriate raw materials is critical for the quality and performance of your CNC parts.

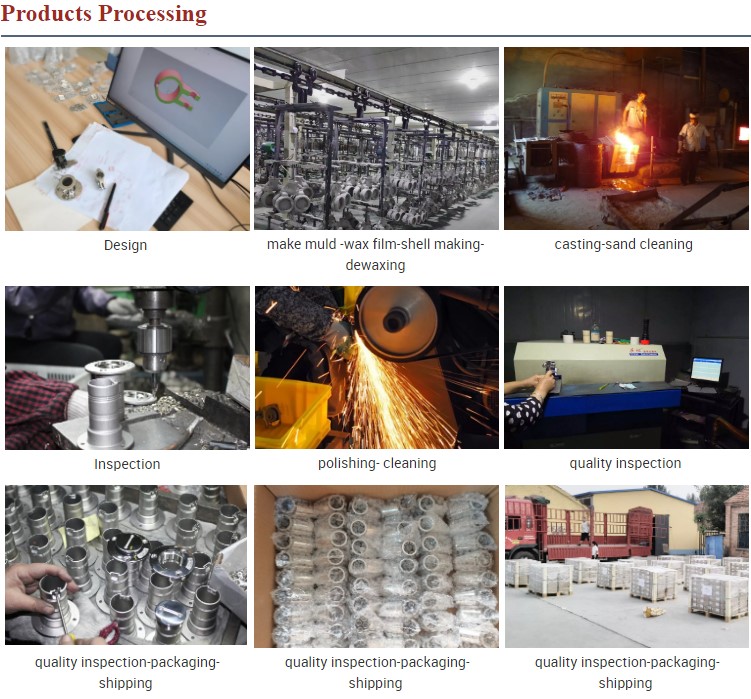

2、Manufacturing Capabilities: Your supplier must have the ability to manufacture parts using CNC techniques. This includes not only the machinery but also the expertise to design and program the machines for optimal performance.

3、Quality Assurance: A reliable CNC supply chain should ensure that the final product meets stringent quality standards. This involves regular inspections, tests, and certifications to verify that the parts meet industry standards and customer requirements.

4、Customization Services: Many businesses require their parts to be custom-designed or modified to meet unique specifications. Your CNC supplier should have the capability to work closely with you to develop solutions that meet these specific requirements.

5、Cost Considerations: Choosing a CNC supplier can be expensive, especially if you're sourcing from overseas or specialized niche markets. It's essential to compare costs across different suppliers, factoring in not only the upfront costs but also the cost of maintenance, spare parts, and labor.

6、Technology Adoption: As industries evolve, so do the technologies used in manufacturing. Your CNC supplier should be able to keep up with the latest advancements in automation, digitalization, and robotics. This ensures that your parts remain competitive and efficient over time.

7、Communication and Collaboration: Building a strong working relationship with your CNC supplier goes beyond just meeting your immediate needs. It requires ongoing communication to ensure smooth operations, coordinate schedules, and address any issues that arise.

8、Sustainability Practices: With environmental concerns becoming increasingly pressing, it's important to consider the impact your CNC supply chain has on the planet. Look for suppliers who prioritize sustainability practices, such as recycling waste materials, minimizing energy usage, and reducing carbon emissions.

9、Flexibility: In an ever-changing market, having a flexible CNC supply chain can mean the difference between success and failure. Your supplier should be able to quickly adjust to changes in demand, market trends, or technological advancements.

10、Legal Compliance: Ensure that your CNC supplier adheres to all relevant legal requirements for exporting, importing, and manufacturing. This may include compliance with international trade agreements like WTO (World Trade Organization), FTAs (Free Trade Agreements), and local regulations.

Case Study of Successful CNC Wholesale

Consider the case of Advanced Manufacturing Systems (AMS), a leading manufacturer of precision hardware components based in the United States. AMS's success lies in their commitment to providing top-notch CNC supplies that align with their customers' demanding specifications.

AMS sources their raw materials from reputable suppliers in China, Europe, and Japan, ensuring the highest quality and consistency in their products. They invest in state-of-the-art manufacturing equipment that enables them to produce CNC parts with unparalleled speed and precision. Their team of skilled engineers and technicians are experts in programming CNC machines to meet specific requirements, whether it's creating intricate shapes or finely controlling the size and finish of individual components.

To ensure that they maintain their position as a leader in the CNC supply industry, AMS implements strict quality control measures. They regularly inspect their products for defects and use advanced testing methods to validate their parts' durability and reliability. They also collaborate closely with their customers to understand their needs better and adjust their processes accordingly.

Moreover, AMS is committed to sustainable practices in their CNC supply chain. By adopting eco-friendly materials and implementing energy-efficient manufacturing processes, they reduce their environmental footprint while still maintaining their competitive edge in the market.

Conclusion

In today's fast-paced world of hardware production, precision and efficiency are key factors that drive growth. CNC supply plays an integral role in this ecosystem, providing businesses with the raw materials, manufacturing capabilities, and expertise they need to succeed. By considering the various aspects discussed in this guide, businesses can select the right CNC wholesale partner that aligns with their goals and objectives. With the right partners by their side, they can achieve unprecedented levels of success in the hardware manufacturing industry.

Articles related to the knowledge points of this article:

Agricultural Hardware Wholesale

Title: Chongqing Hardware Wholesale Market: Your Ultimate Guide

Title: Exploring the World of Small Hardware Wholesale: A Comprehensive Guide to the Best Resources