Customizing Regular Hardware Equipment in Qingyuan, China

In Qingyuan, China, the process of modifying standard hardware equipment has been underway for several years. With the rapid development of modern technology and the increasing demands of the market, traditional manufacturing methods are no longer sufficient to meet the needs of modern society. Therefore, enterprises have begun to explore new ways to improve their production efficiency and product quality through customized modifications to standard hardware equipment. These modifications include but are not limited to the use of new materials, the optimization of production processes, and the addition of advanced technologies such as automation and intelligent control. The benefits of these modifications are significant, including increased production efficiency, improved product quality, reduced production costs, and enhanced flexibility in meeting customer needs. As a result, customized modifications to standard hardware equipment are becoming increasingly important in today's competitive business environment.

Introduction:

In the world of manufacturing, precision and efficiency are paramount. At Qingyuan Industrial Park, a hub for high-tech industries, there is a growing demand for customized regular hardware equipment that can meet the specific needs of local factories and businesses. This article explores the process of customizing hardware equipment in Qingyuan, China, focusing on the importance of collaboration between manufacturers and clients to ensure the final product meets the highest standards.

Customization Process:

The customization process begins with a thorough understanding of the client's needs, including the size, weight, material specifications, and functional requirements. This involves extensive discussions with the client, who may be located in various parts of China but preferably within close proximity to the manufacturing facility. The client provides detailed specifications and any special requirements or constraints that must be adhered to during the design and production stages.

Design and Development:

Once the client's requirements have been fully understood, a team of engineers and designers at the manufacturer's facility begin the process of designing and developing the hardware equipment. This stage involves creating prototypes and conducting testing to ensure the equipment meets all functional and safety standards. Any modifications or adjustments made during this phase are communicated back to the client, who can provide feedback and make further changes.

Material Selection:

The selection of materials for the hardware equipment is critical as it directly affects the strength, durability, and cost of the final product. The manufacturer selects materials based on the client's specifications and recommendations, considering factors such as cost, availability, and compatibility with other components. Quality control measures are implemented throughout the material selection and processing stages to ensure that only the highest-grade materials meet the standards set by the client.

Manufacturing Process:

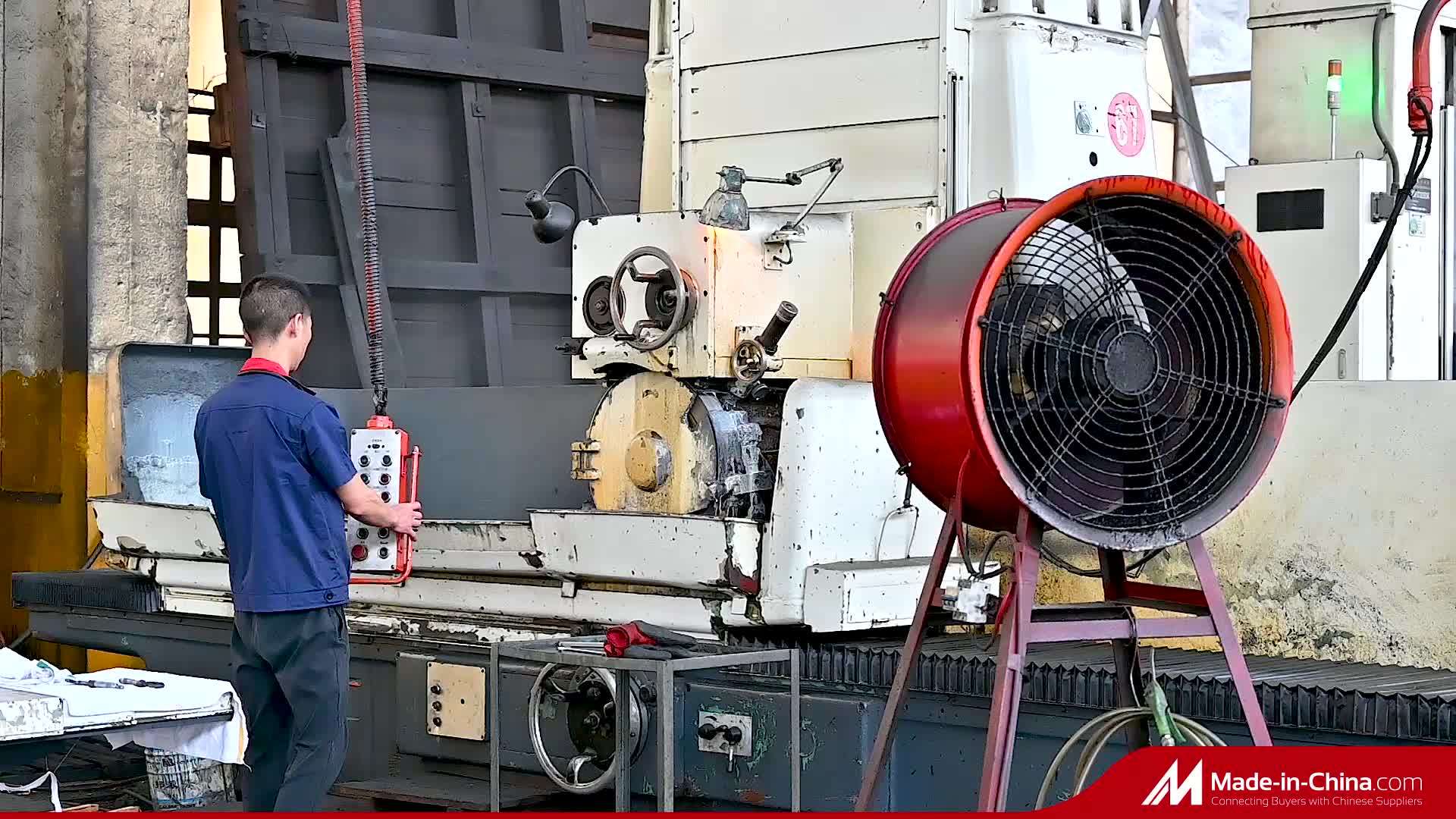

Once the design and materials have been finalized, the next step is to manufacture the hardware equipment. This stage is where craftsmanship and attention to detail become paramount. The manufacturer employs skilled workers who follow precise processes and techniques to ensure that each piece of equipment is of the highest quality. This includes welding, grinding, polishing, and other finishing touches that add to the functionality and aesthetic appeal of the finished product.

Quality Control:

Quality control is an ongoing process throughout the entire customization process. The manufacturer maintains a rigorous system of inspection and testing to ensure that every piece of hardware equipment meets the highest standards. This includes regular checks of the machine's performance, visual inspections of the finished products, and compliance with applicable regulations and industry standards. Any issues found during inspections are promptly addressed, ensuring that the final product is of the highest quality possible.

Packaging and Shipping:

Finally, the customized hardware equipment is packaged and shipped to its destination. The manufacturer uses advanced packaging techniques to protect the equipment during shipping and minimize any damage or scratches that may occur during transit. This ensures that the client receives their investment safely and intact.

Conclusion:

Customizing regular hardware equipment in Qingyuan, China, requires a collaborative effort between manufacturers and clients. By working together, both parties can achieve optimal results, resulting in high-quality, durable, and efficient equipment that meets the specific needs of local factories and businesses. The importance of effective communication, meticulous design and development, careful material selection, attention to detail in the manufacturing process, and strict quality control cannot be overstated. With these key elements in place, customized hardware equipment in Qingyuan is not just a business opportunity but a commitment to excellence that delivers exceptional value to customers around the globe.

Articles related to the knowledge points of this article:

Custom Non-Standard Hardware Manufacturing in China

Title: Exploring the Beauty and Quality of Jinan Bathroom Hardware Customization Stores

Title: Crafting Custom Furniture Hardware: The Art of Creating Unique and Functional Pieces

LISHUI Ouwei Customized Hardware: Quality and Innovation

Title: Customized Metal Hardware and Aluminum Components in Kunming: A Comprehensive Guide