五金配件抛光厂

This article discusses the process of polishing hardware accessories, which is an essential step in the manufacturing process of various metal products. The article explains that the quality and appearance of these products can be greatly improved through the proper polishing process. This process involves using specialized equipment and chemicals to remove any scratches, nicks, or imperfections from the surface of the product.The article also highlights the importance of maintaining a consistent level of polish throughout the entire production process. This is achieved through the use of specialized machines and techniques that ensure a uniform and even surface finish. The result is a product that is not only visually appealing but also functional and durable.In conclusion, the polishing process is a crucial step in the manufacturing process of many different types of hardware accessories. By following proper guidelines and techniques, manufacturers can achieve a high level of quality and consistency in their products, which ultimately leads to increased customer satisfaction and market success.

"Improving Quality with the Power of Precision - A Comprehensive Guide to Equipment Polishing in the Hardware Accessory Manufacturing Industry"

Introduction:

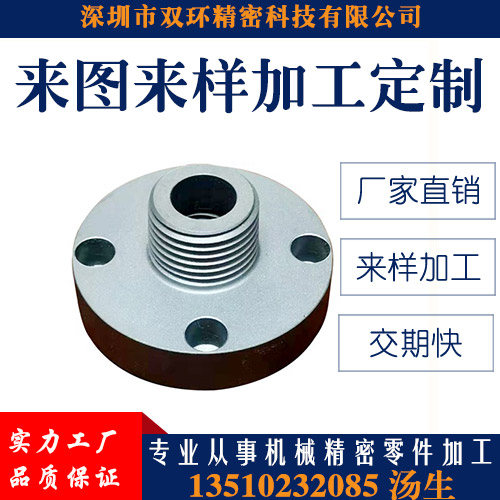

In the world of hardware manufacturing, where precision and durability are paramount, the process of equipment polishing stands as a crucial step towards achieving these standards. As machines and parts become more complex, the need for high-quality finish has never been greater. At our specialized 五金配件抛光厂, we specialize in providing unparalleled precision in our equipment polishing processes, ensuring that every part meets the highest quality standards. In this comprehensive guide, we will explore the importance of precision in polishing, the techniques involved, and the benefits it brings to your product's performance.

Precision in Equipment Polishing: What It Means for Your Products?

At its core, precision in equipment polishing is about reducing the amount of surface roughness on your parts, which directly affects their durability, functionality, and overall performance. When machined or assembled parts have a smooth surface, they require less force when being used, resulting in longer tool life and increased accuracy. Additionally, a smoother surface allows for better lubrication, preventing wear and tear and extending the useful life of your machinery.

Why Is Precision Crucial in Finishing Processes?

The reasons why precision is essential in finishing processes are numerous. For one, it reduces the likelihood of defects, such as burrs and scratches, which can compromise the function and safety of your products. Moreover, a higher degree of precision often translates to a more efficient production line, as well as improved product consistency across batches. Finally, precision in finishing contributes to a company's reputation by showcasing their commitment to excellence in materials and manufacturing processes.

Types of Equipment Polishing Techniques:

There are several types of equipment polishing techniques available, each designed to achieve specific results. The most common methods include:

1、Wheel Polishing: Using abrasive wheels to remove material from surfaces. This technique is fast and effective but requires careful control to avoid excessive wear or damage to the workpiece.

2、Belt Polishing: A slower method that uses a belt that applies pressure to the workpiece. This approach is ideal for delicate parts that may be easily damaged during other methods.

3、Circular Sawing: A method that involves cutting away material from a circular pattern around the workpiece. It’s suitable for removing large amounts of material and creating a uniform surface finish.

4、Wire Drawing: This technique uses thin wire to draw out imperfections from the surface of the workpiece. The wire is then removed, leaving behind a polished surface.

5、Sandblasting: A method that uses a stream of fine sand particles to remove material from a workpiece. It’s an effective way to create a smooth surface but requires careful attention to avoid damaging the workpiece.

Benefits of Precision in Finishing Processes:

Beyond the tangible advantages mentioned above, precision in equipment polishing also has a significant impact on the bottom line. By investing in precision equipment, manufacturers can significantly reduce costs associated with scrap, rework, and replacement parts. Additionally, precision finishes often result in increased product sales and customer satisfaction, as customers appreciate the superior performance of their products.

Conclusion:

The importance of precision in equipment polishing cannot be overstated. It’s not just about making things look nicer; it’s about ensuring that your products meet the needs of the market and stand the test of time. At our 五金配件抛光厂, we understand the significance of precision and are committed to providing you with the highest quality finish possible. With our expertise and state-of-the-art equipment, we are confident we can help you achieve your goals and exceed your expectations. Contact us today to learn more about how we can transform your products with precision.

Articles related to the knowledge points of this article:

Switch Hardware Accessories: An Integral Part of Electrical Systems

Glass and Hardware Accessories Wholesale: A Comprehensive Guide

The Development of Leather and Hardware Accessories for Boxes and Bags

Title: The Evolution and Importance of Stainless Steel Belts in Hardware Accessories