Custom Metal Damping Solutions

Custom Metal Damping Solutions are designed to effectively reduce vibrations and noise in metal structures. These solutions, tailored to specific applications, improve the performance and durability of metal components in various industries. By integrating advanced damping technologies, these solutions ensure optimal performance and longevity of metal assets. Whether it is for aerospace, automotive, or industrial applications, Custom Metal Damping Solutions provide a cost-effective way to enhance the performance of metal components. These solutions are designed to meet the unique needs of each customer, ensuring optimal results that contribute to the overall success of their business.

Metal damping is a crucial aspect of many engineering and industrial applications, offering numerous benefits such as reducing vibration, preventing damage, and increasing performance. When it comes to tailor-making metal damping solutions, there are several key factors to consider to ensure the most effective and economical outcome.

Firstly, the type of metal to be used is a significant decision. Different metals have unique properties that make them more or less suitable for specific applications. For instance, steel is renowned for its durability and strength, making it an excellent choice for high-stress environments where vibration needs to be controlled effectively. On the other hand, aluminum is lighter and more malleable, making it ideal for applications where weight and cost are major concerns.

Secondly, the design of the metal damping solution is crucial. The shape, size, and configuration of the damping components can significantly impact performance and effectiveness. Customizing these designs to meet specific application requirements is essential to ensure optimal results. This is where advanced engineering software and CAD tools come into play, allowing designers to create tailored solutions that are both functional and cost-effective.

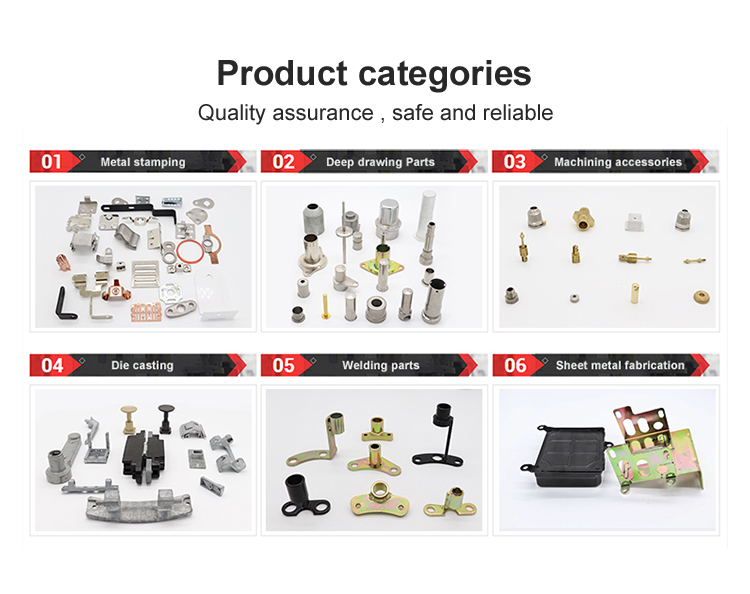

Thirdly, the manufacturing process is another crucial aspect of custom metal damping solutions. Different manufacturing techniques, such as machining, molding, or extrusion, can significantly affect the final product's properties and performance. Choosing the right manufacturing process can help to ensure that the damping solution not only meets the application's needs but also offers good value for money.

Fourthly, quality assurance is essential when it comes to custom metal damping solutions. Ensuring that the final product meets all specified standards and requirements is crucial to ensure its reliability and performance over time. This may involve rigorous testing procedures such as vibration testing, temperature testing, and chemical resistance testing to ensure that the damping solution can withstand the challenges of its intended environment.

In conclusion, custom metal damping solutions are crucial to many engineering and industrial applications. By considering the type of metal, design, manufacturing process, and quality assurance, it is possible to tailor-make effective and economical damping solutions that meet specific application requirements. These solutions can help to reduce vibration, prevent damage, and increase performance, ultimately leading to longer equipment life and reduced maintenance costs.

Articles related to the knowledge points of this article:

Title: Customized Metal Hardware and Aluminum Components in Kunming: A Comprehensive Guide

Title: Customized Metal Racks and Shelving Units in Wenzhou: A Comprehensive Guide

Zhoushan Undertakes Customized Hardware Production

Customized Shanghai Hardware Labeling Machines: A Guide to Selecting the Right One for Your Business