The Ultimate Guide to Wholesale Hardware Grinders for Your Industrial Needs

This comprehensive guide provides a detailed analysis of the best wholesale hardware grinders available in the market, catering to your industrial needs. The primary focus is to provide you with the essential information required to make an informed decision and choose the best grinder for your specific application. The guide covers various factors such as the type of material being ground, the desired grind size, the grinding process, and more. It also provides an overview of different types of hard drive grinders, including hammer mills, ball mills, and rod mills, their advantages, and disadvantages, and their applications. Additionally, the guide discusses the maintenance and operational aspects of these grinders, highlighting the importance of regular cleaning and servicing to ensure optimal performance and longevity. Finally, the guide concludes by providing tips on how to choose the right grinder based on your specific needs, ensuring that you get the most out of your investment.

Introduction

The realm of industrial machinery is a vast and complex one, where precision and functionality are paramount. Among the essential pieces that keep machinery running smoothly is the humble hardware grinder. This essential tool serves as the pivotal component in various manufacturing processes, from cutting metals to grinding components, and it's no wonder that the wholesale market for these grinders is booming with demand. In this comprehensive guide, we will explore the ins and outs of wholesale hardware grinders, from their classification to how they function and how you can effectively purchase them for your business's needs.

Types of Hardware Grinders

Before diving into the buying process, it's important to understand what different types of hardware grinders are available and their applications. There are several categories of grinders, each with its unique set of features and uses:

1、Universal Grinders: These versatile machines can handle a wide range of materials and sizes, making them ideal for a variety of industrial settings. They come with adjustable speeds and grinding patterns for precise control over cutting and grinding tasks.

2、Wire Wheel Grinders: These grinders use a wire wheel to cut and shape metal parts. They are highly effective in removing material and creating intricate shapes. However, they are typically bulkier and more expensive than other grinders.

3、Ball Grinding Machines: These grinders use a series of balls to apply pressure and force on the workpiece, which helps break down tough materials like cast iron. Ball grinding machines offer high efficiency and low cost per unit of work.

4、Cone Grinders: Also known as impact grinders, cone grinders are designed to remove large amounts of material quickly and efficiently. They come in various sizes and configurations, allowing for customized solutions tailored to specific applications.

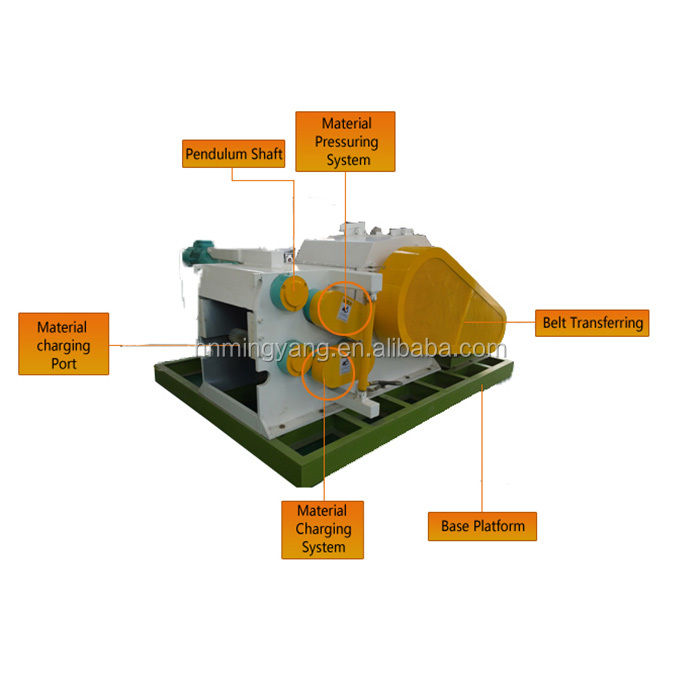

5、Sawmill Grinders: These are specialized machines that combine cutting and grinding functions, making them ideal for shaping and polishing metal parts. They offer a clean and efficient cutting edge that minimizes burring and tearout.

How to Choose the Right Hardware Grinder

When selecting a grinder for your industrial needs, there are several factors to consider:

Material: Determine the type of metal or material you need to grind first. This will influence the choice of grinder. For instance, if you deal with aluminum or stainless steel, a ball grinder may be the best option. If you need to grind hardened or cast iron, opt for a sawmill grinder or an impact machine.

Size: The grinder's capacity or size should match your production volume. You want to ensure that the grinder you select can handle your current and future needs without becoming overwhelmed or requiring frequent maintenance.

Speed: The grinder's speed is crucial for achieving the desired level of accuracy, speed, and productivity. Consider the speed range of the grinder and determine whether it fits within your production cycle.

Power Requirement: Depending on the size of the grinder, its power requirements will vary. Make sure to check the motor's horsepower and energy efficiency rating before making any commitments.

Cost: While quality and performance are important, don't skimp on costs. Evaluate the total cost of ownership, including maintenance expenses, replacement parts, and labor costs.

Professional Advice and Support

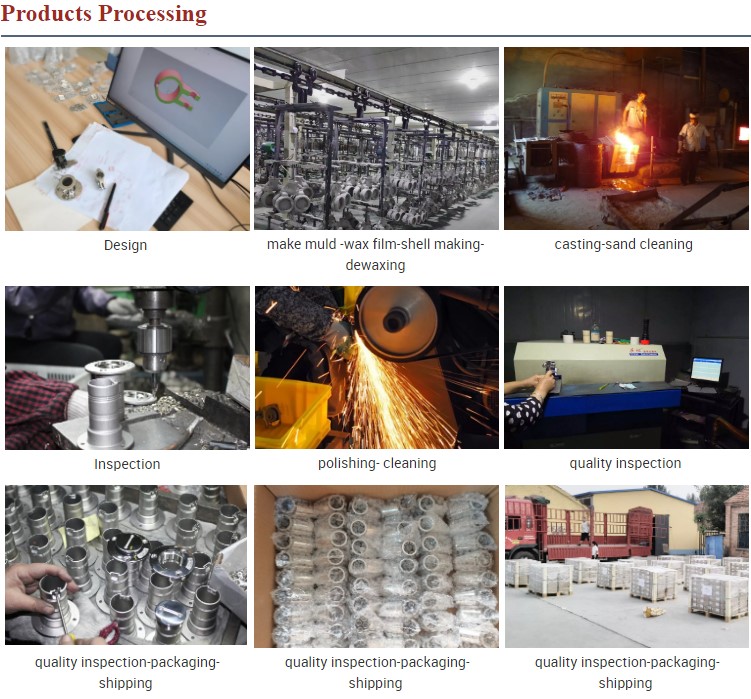

While purchasing hardware grinders can seem overwhelming at first, investing in the right equipment is critical to maintaining a smooth workflow and maximizing productivity. To make informed decisions, consider seeking professional advice from industry experts or consulting with manufacturers. They can provide insights into the latest trends, product specifications, and best practices for your specific application.

Additionally, consider sourcing spare parts and maintenance services from reputable suppliers. A reliable supplier can ensure that you have access to quality replacement parts when needed, saving you time and money in the long run.

In conclusion, choosing the right hardware grinder for your needs involves careful consideration of various factors such as material, size, speed, power requirement, and cost. By doing so, you can ensure that you get the most out of your investment, resulting in increased efficiency, reduced downtime, and improved product quality. Don't hesitate to explore options and seek professional guidance to find the perfect grinder for your industrial machinery needs.

Articles related to the knowledge points of this article:

Title: Datong Hardware Cable Wholesale

Title: Jiangmen Hardware Wholesale Market: A Comprehensive Guide

Title: Guangdong Hardware and Electrical Materials Wholesale

Xinjiang Building Materials and Hardware Wholesale

Title: Custom Hardware Wholesale in Beijing

Title: Exploring the Wonders of Yongkang Hardware Wholesale Market