Exploring the World of Hardware Castings: A Wholesale Perspective

Hardware castings play a crucial role in the manufacturing process of various products, from automotive parts to construction equipment. Wholesalers are essential in sourcing and distributing these castings to businesses across industries. The global hardware castings market has seen significant growth over the years, driven by advancements in technology, increasing demand for industrial products, and globalization. Key players in the industry include manufacturers, distributors, and wholesalers. In this article, we will explore the world of hardware castings from a wholesale perspective, discussing trends, challenges, and opportunities in the market. We will also examine the impact of factors such as supply chain management, pricing, and market dynamics on the industry's growth and success. By understanding the complexities of the hardware castings wholesale market, businesses can make informed decisions about sourcing and distributing castings to meet their needs and stay competitive in an ever-changing global marketplace.

Hardware castings are a vital component in manufacturing processes across various industries, including automotive, construction, and aerospace. They are widely used in applications such as engine parts, gears, bearings, and other mechanical components. The global hardware castings market is expected to grow at a significant rate in the coming years, driven by increasing demand from emerging economies and advancements in technology. This article explores the world of hardware castings, focusing on the wholesale aspect of the industry.

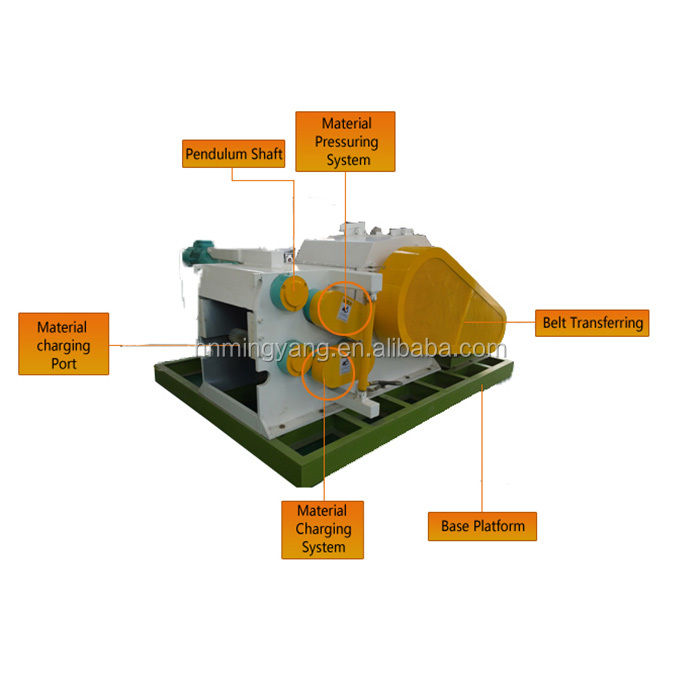

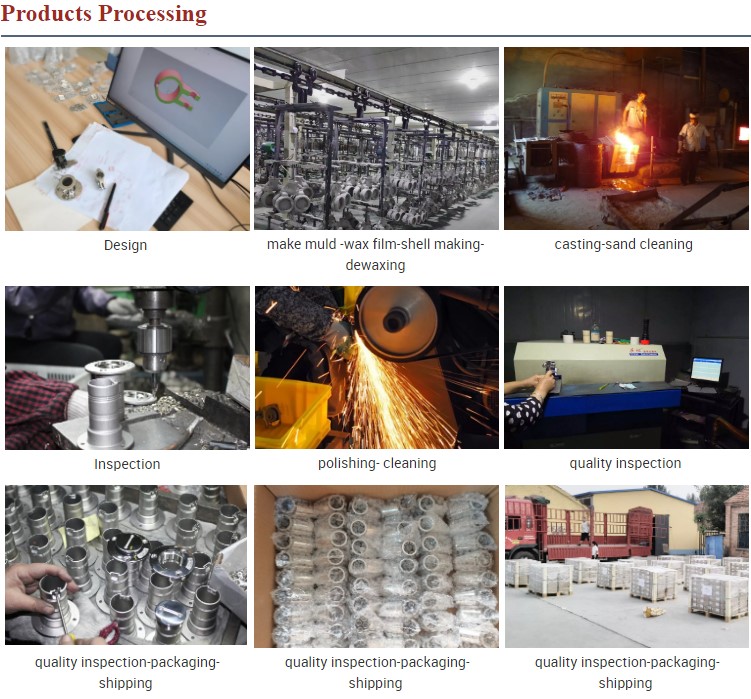

Hardware castings are produced using a variety of techniques, including investment casting, sand casting, die casting, and lost foam casting. Each technique has its advantages and disadvantages based on the specific requirements of the application. Investment casting is a popular method for producing small to medium-sized parts with intricate details, while sand casting is suitable for large-scale production of simple or complex shapes. Die casting is an efficient method for producing high-quality metal parts with precise dimensions and smooth surfaces, while lost foam casting is a cost-effective option for producing lightweight parts with minimal waste.

Wholesale suppliers of hardware castings offer a wide range of products to meet the diverse needs of customers worldwide. These suppliers typically have established relationships with manufacturers and can offer competitive prices and prompt delivery times. In addition, they often provide customization services to produce parts tailored to the specific requirements of customers. Some of the key factors to consider when selecting a wholesale supplier include product quality, pricing, delivery time, and customer service.

Product Quality:

The quality of hardware castings is critical to ensuring their reliability and longevity in industrial applications. Wholesale suppliers must work closely with manufacturers to ensure that the raw materials, production processes, and final inspections meet strict standards. Key quality parameters to monitor during the supply chain include material purity, dimensional accuracy, surface finish, and corrosion resistance. By maintaining high standards of product quality, wholesale suppliers can build trust with customers and maintain a competitive advantage in the market.

Pricing:

Pricing is one of the most important factors influencing purchasing decisions for hardware castings. Wholesale suppliers must balance the need to remain competitive with the desire to generate profit. To this end, they may offer different pricing structures depending on the quantity, size, and complexity of the order. Some suppliers may offer volume discounts for larger orders or specialize in certain types of products to differentiate themselves from competitors. It is essential for customers to compare prices and terms from multiple suppliers before making a decision.

Delivery Time:

Prompt delivery is crucial for businesses operating in time-sensitive industries such as automotive and aerospace. Wholesale suppliers must have efficient logistics systems in place to ensure that orders reach customers on time. This may involve working with transportation providers that offer express shipping options or having inventory available for immediate dispatch. Customers should communicate any time constraints clearly when placing an order to help suppliers prioritize and plan accordingly.

Customer Service:

Good customer service is essential for building long-term relationships with customers and retaining their business. Wholesale suppliers must be responsive to customer inquiries and concerns throughout the entire buying process, from initial contact to delivery and after-sales support. This may involve providing technical assistance, offering product recommendations, or resolving issues promptly. By prioritizing customer satisfaction, suppliers can establish themselves as trusted partners and enhance their reputation in the industry.

Conclusion:

In conclusion, hardware castings are an integral part of modern manufacturing, and the wholesale sector plays a significant role in distributing these products worldwide. By understanding the various techniques used in hardware castings production, exploring the world of hardware castings wholesale, and considering key factors such as product quality, pricing, delivery time, and customer service, businesses can make informed decisions when selecting a supplier to meet their needs. As the global hardware castings market continues to grow, it is essential for suppliers to adapt and innovate to stay competitive in this dynamic landscape.

Articles related to the knowledge points of this article:

Title: Windows and Doors Hardware Wholesale Manufacturer

How to Set Prices for Hardware Wholesale

Title: Exploring the Marvel of Chinas Foshan South China Hardware Wholesale Market

Urumqi Hardware Handle Wholesale: Quality and Selection for Your Projects