Painting Solutions for Hardware Stores: The Art of Coating Metal Products

The art of coating metal products is crucial to the success of hardware stores. The right paint solution can enhance the durability, corrosion resistance and aesthetic appeal of metal products. Hardware stores must choose the appropriate coating for each product type and application. The choice of paint depends on factors such as the metal substrate, environmental conditions and intended use. Painting solutions must be applied with precision to ensure a smooth and uniform finish. Hardware stores that invest in proper paint solutions can provide their customers with high-quality products that are built to last. With the right paint solution, hardware stores can elevate their products from ordinary to extraordinary, providing customers with a superior shopping experience.

Introduction

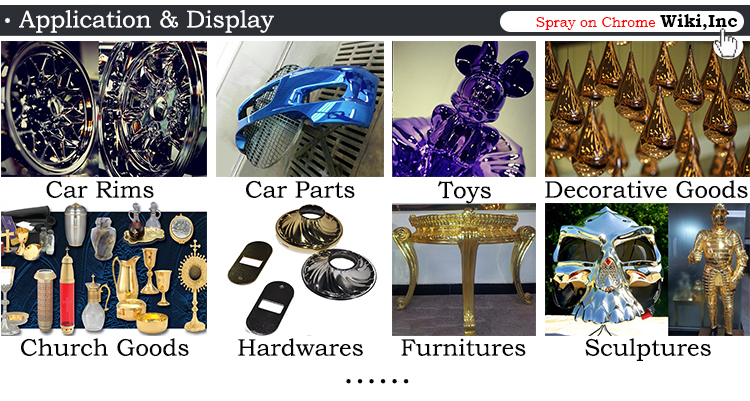

The world of hardware stores is a vast and ever-evolving industry that caters to the needs of homeowners, contractors, and DIY enthusiasts. At the heart of this industry are the metal products that form the foundation of construction, renovation, and repair projects. From door handles and window locks to fence posts and shed doors, these products require regular maintenance to ensure their longevity and performance. One essential aspect of maintaining metal products is coating them with a protective layer of paint or varnish. This process not only enhances the visual appeal of the product but also provides protection from environmental factors such as rust, corrosion, and UV rays. In this article, we will explore the art of painting metal products in hardware stores and the different techniques and tools used by professional painters.

Choosing the Right Paint for Metal Products

When it comes to painting metal products, there are several factors to consider, including the type of metal, the environment in which the product will be used, and the desired finish. The first step in selecting the right paint is to determine the type of metal. There are four main categories of metals used in metal fabrication: aluminum, steel, iron, and wrought iron. Each type of metal has its own unique properties and requires specific treatment before painting. For example, aluminum is highly reactive and can corrode easily, while steel is prone to rust formation. Therefore, it is important to choose a paint that is designed specifically for each metal type.

Once the metal type has been determined, the next step is to consider the environment in which the product will be used. Metal products that will be exposed to harsh weather conditions such as rain, snow, or strong winds should be coated with a more durable paint than those that will be indoors. Additionally, if the product will be used in areas with high levels of humidity or moisture, it is important to choose a paint that is resistant to mildew and mold growth.

Finally, the desired finish is an important consideration when selecting paint for metal products. There are several types of finishes available for metal products, including flat, matte, gloss, and semi-gloss. Each finish has its own set of benefits and disadvantages, and the choice ultimately depends on personal preference and the intended use of the product. For example, a flat finish is ideal for outdoor metal products that will be exposed to sunlight, while a glossy finish is better suited for indoor metal products that require a high level of shine.

Preparing Metal Products for Painting

Before applying paint to metal products, it is essential to prepare the surface thoroughly. This involves cleaning the metal surface using a degreaser or sandpaper to remove any dirt, oil, or rust. It is important to work slowly and carefully when cleaning metal surfaces to avoid damaging them. Once the surface has been cleaned, it should be dried completely before applying paint.

Applying Paint to Metal Products

There are several methods for applying paint to metal products, including brushwork, roller application, and spraying. The method chosen will depend on the size of the project, the level of accuracy required, and personal preference. When using a brush or roller, it is important to apply light coats of paint rather than thick ones, as this will help prevent drips and streaks from forming. If using a spray gun, it is important to maintain a consistent distance between the gun and the surface being painted and to hold the gun at an angle to avoid spreading paint too far.

To achieve even coverage and prevent peeling or flaking of paint, it is important to follow proper painting techniques such as priming before painting and allowing sufficient time for drying between coats. It may also be necessary to use a primer specifically designed for metal surfaces to provide additional protection against rust and corrosion.

Conclusion

Painting metal products in hardware stores requires careful planning, selection of appropriate paint and tools, and adherence to proper painting techniques. By following these guidelines, professional painters can ensure that their metal products are coated with a durable and long-lasting protective layer that enhances their visual appeal while providing essential protection against environmental factors. Whether you're a homeowner repairing a damaged fence or a contractor renovating a building, understanding the art of painting metal products is an essential skill that can help ensure success in your projects.

Articles related to the knowledge points of this article:

Title: The Profitability of Opening a Small Hardware Store Monthly

Jiaozhou Hardware Store: Quality Hardware, Unbeatable Prices

Title: The Cost of Bicycle Tires in a Hardware Store: A Comprehensive Guide

Title: The Salary of a Hardware Store Salesperson: A Comprehensive Analysis

Title: The Cost of a 15-Square-Meter Hardware Store: A Comprehensive Guide

Title: Is the Water Inlet of Washing Machines Available for Sale in Hardware Stores?