Customized Metal Stampings in Yancheng: A Comprehensive Guide

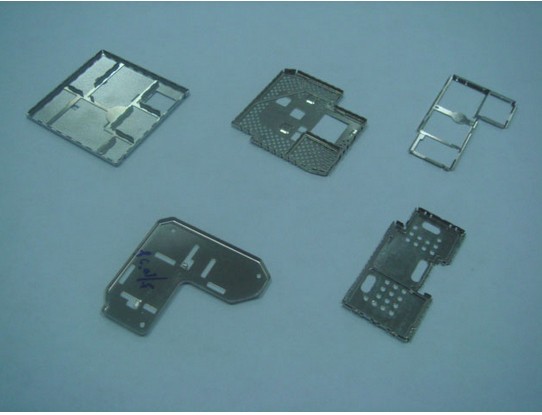

Yancheng is known as the "hometown of customized metal stampings" in China. With a rich history and advanced technology, Yancheng has become an important center for customized metal stampings production in Asia. The city's comprehensive industry chain, from design to production, ensures high-quality products and efficient service. Custom metal stampings can be used in various industries, including automotive, medical, electronic, and aerospace. The processing techniques include punching, bending, welding, and polishing. The quality control measures are rigorous and include material testing, dimensional inspection, and surface treatment. The market demand for customized metal stampings is continuously growing due to its flexibility, durability, and cost-effectiveness. Many well-known companies in the world have established their own subsidiaries or partnerships in Yancheng to meet the rising demand. In summary, Yancheng's customized metal stampings industry offers a competitive advantage with its advanced technology, skilled workforce, and comprehensive industry chain. It is an excellent choice for businesses looking to expand their global reach and increase efficiency.

Yancheng, a city located in eastern China's Jiangsu Province, has long been recognized for its expertise in metal stampings. With a rich history of over a century, the city boasts a comprehensive range of services, from simple metal blanks to complex, high-precision components. This article aims to provide an in-depth look at the process of producing customized metal stampings in Yancheng, highlighting key aspects such as design, production, and quality control.

The first step in creating custom metal stampings in Yancheng is the design phase.yancheng's experienced engineers work closely with clients to develop precise specifications for the final product. This may include determining the material type (steel, aluminum, or other), the shape and size of the parts, and any necessary surface finishing. With the help of cutting-edge technology, designers can create detailed 3D models and simulate the performance of the finished product, ensuring client satisfaction.

Once the design is finalized, production begins in Yancheng's state-of-the-art factories. These facilities employ the latest machinery and automation technologies to produce high-volume runs of metal stampings quickly and efficiently. The production process usually involves several steps, including blanking, punching, bending, and welding. Each stage requires strict quality control measures to ensure that the parts meet the specified requirements.

In addition to standard sizes and shapes, Yancheng also offers custom metal stamping services, allowing customers to create truly unique components. For example, some manufacturers specialize in creating specialized brackets or hardware that meets specific architectural or engineering requirements. Others may offer customization options for surface finishing or add visual elements such as branding or decorative patterns.

Quality control is a top priority at every stage of the Yancheng metal stamping process. From raw materials to final products, rigorous testing is conducted to ensure compliance with industry standards and customer requirements. Inspection procedures include visual inspection, dimensional accuracy checks, material tests, and functional testing. Any defects or issues are promptly addressed to maintain consistent quality levels.

Yancheng's metal stamping industry has also been investing in innovation and research to improve efficiency and productivity while maintaining environmental sustainability. Some recent developments include the use of artificial intelligence and machine learning to optimize production processes and reduce waste. Additionally, many companies have implemented green initiatives like recycling programs and energy conservation measures to minimize their carbon footprint and contribute to a sustainable future.

In conclusion, Yancheng's metal stamping industry offers a comprehensive solution for custom manufacturing needs. From initial design to final delivery, the city's dedicated team ensures superior quality and prompt service. As businesses continue to seek cost-effective and efficient solutions for their manufacturing processes, Yancheng's metal stamping industry will undoubtedly remain a vital player in the global market.

Articles related to the knowledge points of this article:

Title: Custom Hardware Solutions in Taizhou, China

ANHUI CUSTOMIZED HARDWARE PRODUCTS IN STOCK

Custom Cabinet Hardware Glue: The Ultimate Guide

Title: Crafting Custom Metal Products: The Art and Science of Bag and Trunk Hardware Manufacturer