Custom Metal Stamping Presses: A Comprehensive Guide

This comprehensive guide to custom metal stamping presses introduces readers to the world of metal stamping presses and their customization. The guide explains the basic concepts, operations, and applications of metal stamping presses, providing a solid foundation for understanding this important manufacturing process. It then delves into the world of customization, showing how to tailor these presses to specific needs and requirements. The guide concludes with a series of tips and best practices to help users get the most out of their custom metal stamping presses. Whether you're new to the field or an experienced professional, this guide has something for everyone.

Metal stamping presses are crucial components in various industries, offering precision and efficiency in the manufacturing process. In this article, we explore the world of custom metal stamping presses, providing a comprehensive guide to help you understand the importance and benefits of these machines.

What are Custom Metal Stamping Presses?

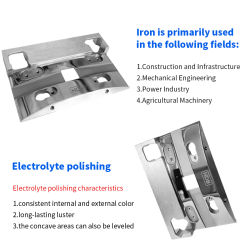

Custom metal stamping presses are machines designed to shape metal parts by applying pressure to a metal sheet or blank. These presses are tailored to meet the specific needs of each industry, offering precision, efficiency, and versatility in the manufacturing process. By customizing the design and specifications of these presses, manufacturers can achieve optimal results for their unique applications.

Benefits of Custom Metal Stamping Presses

1、Precision: Custom metal stamping presses offer precision manufacturing capabilities that ensure the accuracy and quality of each metal part produced. These presses feature advanced technology and precision components that enable them to shape metal parts with high levels of accuracy and repeatability. This ensures that each part meets the specifications and requirements of the application, providing a high-quality finished product.

2、Efficiency: Custom metal stamping presses provide significant efficiency advantages over traditional manufacturing methods. By automating the manufacturing process, these presses can reduce labor costs and increase productivity. Additionally, they offer faster turnaround times and reduce the need for secondary operations, such as drilling, tapping, or milling. This helps to streamline the manufacturing process and improve overall efficiency.

3、Versatility: Custom metal stamping presses exhibit high levels of versatility, offering manufacturers the ability to produce a wide range of metal parts and components. These presses can accommodate different materials, shapes, and sizes, providing flexibility in the manufacturing process. By changing the tooling and die sets, manufacturers can easily transition from one application to another, increasing their capacity to meet diverse customer needs.

4、Cost-effectiveness: Custom metal stamping presses offer cost-effective manufacturing solutions that help manufacturers achieve optimal performance while minimizing expenses. By automating the process and reducing labor costs, these presses enable manufacturers to produce high-quality metal parts at lower costs. Additionally, they reduce the need for secondary operations and reduce overall production time, further reducing expenses and increasing profitability.

5、Customization: Custom metal stamping presses enable manufacturers to tailor their manufacturing process to meet the specific needs of each application. By designing custom tooling and die sets, manufacturers can create unique parts that meet their specific specifications and requirements. This level of customization allows manufacturers to differentiate their products from competitors and create unique solutions that meet their customer needs.

In conclusion, custom metal stamping presses offer precision, efficiency, versatility, cost-effectiveness, and customization benefits that help manufacturers achieve optimal performance in their manufacturing process. By understanding the importance and benefits of these machines, manufacturers can make informed decisions about their manufacturing strategy and improve their overall competitiveness in the market.

Articles related to the knowledge points of this article:

CUSTOMIZED METAL COMPONENTS FOR YOUR SPECIFIC NEEDS

Custom Cabinet Hardware in Zhengzhou

Custom Metal Plate Manufacturers

CUSTOM METAL DISPLAY BOARD IMAGES

Title: Customization of Metal Panel Stamping Processing: A Comprehensive Guide